Anti-extruding stretch-proof power cable

A power cable and tensile-resistant technology, applied in the field of power cables, can solve the problems of power cable extrusion, insulation layer performance change, conductor temperature rise, etc., to achieve the effect of extending service life, improving performance, and maintaining straightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

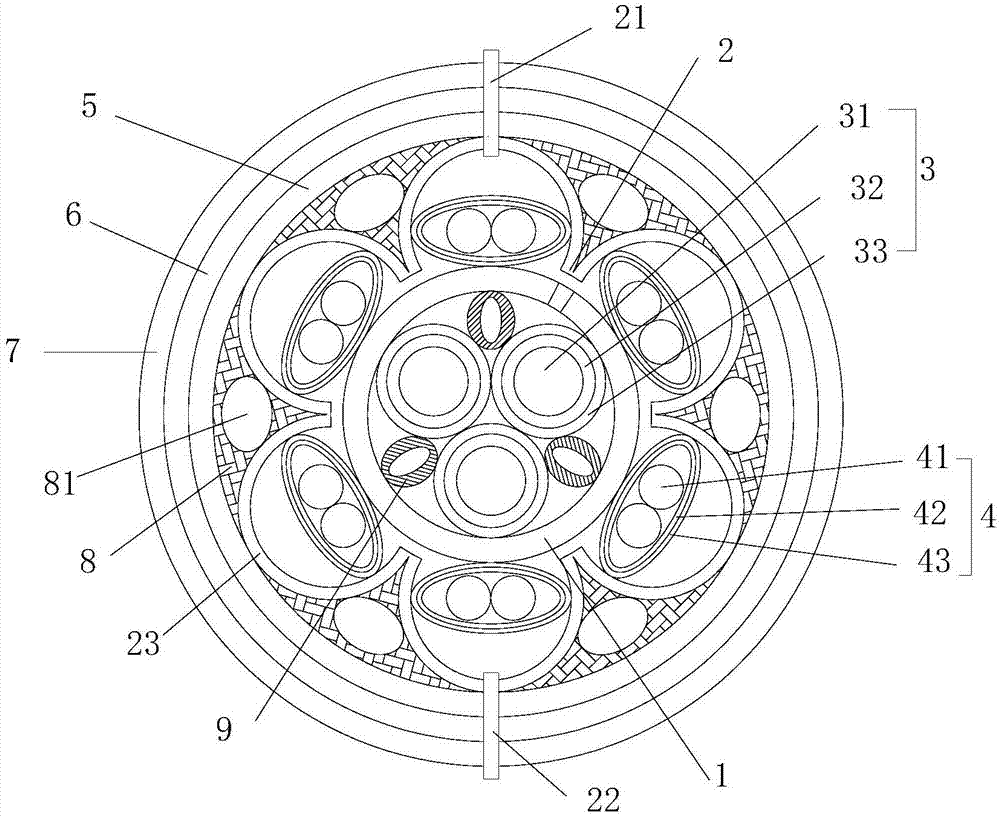

[0018] refer to figure 1 , the present invention proposes an anti-extrusion and stretch-resistant power cable, including a first elastic tube 1, a second elastic tube 2, three first conductors 3 and six second conductors 4, wherein:

[0019] The first elastic tube 1 is arranged on the inner side of the second elastic tube 2, and the first elastic tube 1 is provided with an air guide hole 11 communicating with the inner cavity of the first elastic tube 1 and the inner cavity of the second elastic tube 2; the second elastic tube 2 is composed of six The arc-shaped elastic parts 23 are sequentially connected end to end, and the arc-shaped openings of each arc-shaped elastic part 23 face the first elastic tube 1, and the outside of the second elastic tube 2 is wrapped with an inner sheath 5, a total shielding layer 6, and an outer sheath in turn. 7. Both the first elastic tube 1 and the second elastic tube 2 are filled with gas, and the air inlet pipe 21 and the air outlet pipe 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com