Ageing test device for PE pipes under fluctuating pressure and lifetime prediction method

A technology of aging test and aging device, which is applied in the direction of applying repeated force/pulsation force to test the strength of materials, measuring devices, instruments, etc., which can solve problems such as deviation and achieve low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

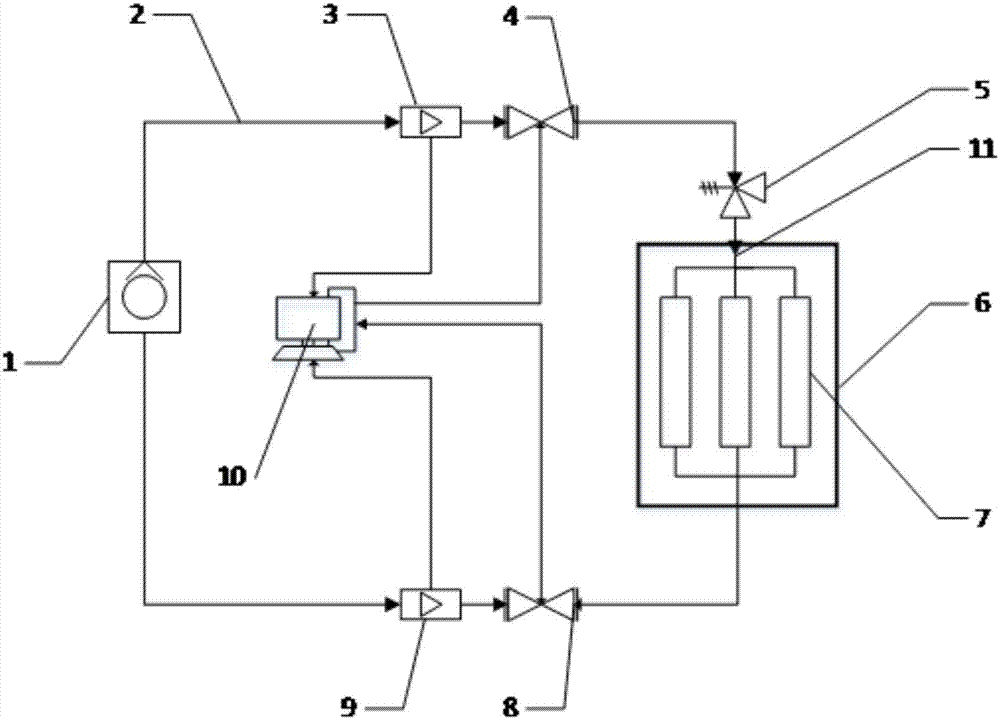

[0028] see figure 1 , which is a structural schematic diagram of an aging test device for PE pipes under fluctuating pressure in this embodiment. The aging test device includes a compressor 1, a pipeline 2, an oven 6, a first pressure sensor 4, a first electric control valve 3, a second pressure sensor 8, a second electric control valve 9, a central controller 10 and a pressure reducing valve 5.

[0029] The compressor 1 and the oven 6 are connected through a pipeline 2 to form a circulation loop, and the test pipe section 7 is placed in the oven 6 .

[0030] Specifically, the compressor 1 serves as a gas generating device to provide a gas load for the pipeline, and also serves as an air extraction device to ensure that the gas load in the pipeline fluctuates within a certain range. The oven 6 plays the role of heating, providing high-temperature environmental stress to age the test pipe section 7 . A sealing ring is tightly fitted between the pipeline 2 and the oven 6 to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com