Shifting device for a motor vehicle transmission

A technology for vehicles and shifting devices, which is applied in the directions of transmissions, transmission parts, transmission control, etc., can solve problems such as high power loss, and achieve the effect of increasing torque transmission capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

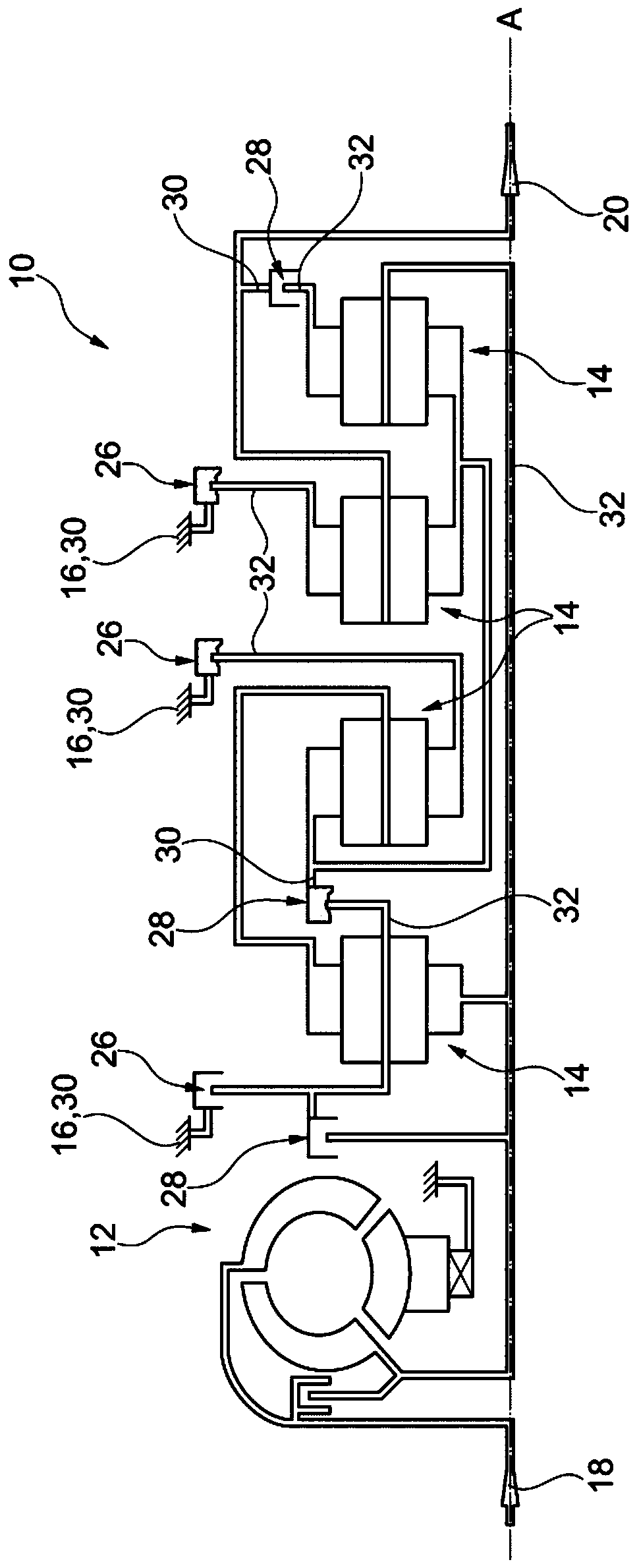

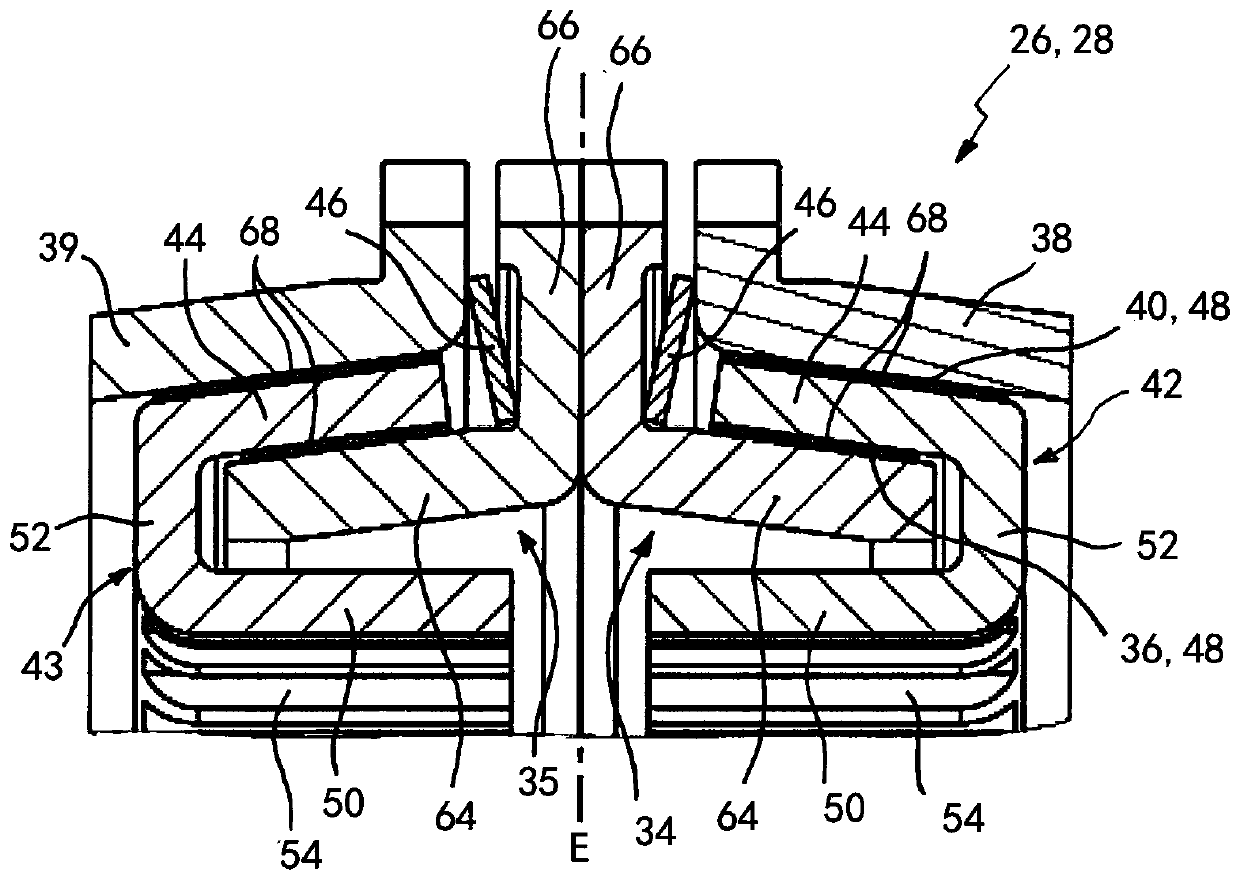

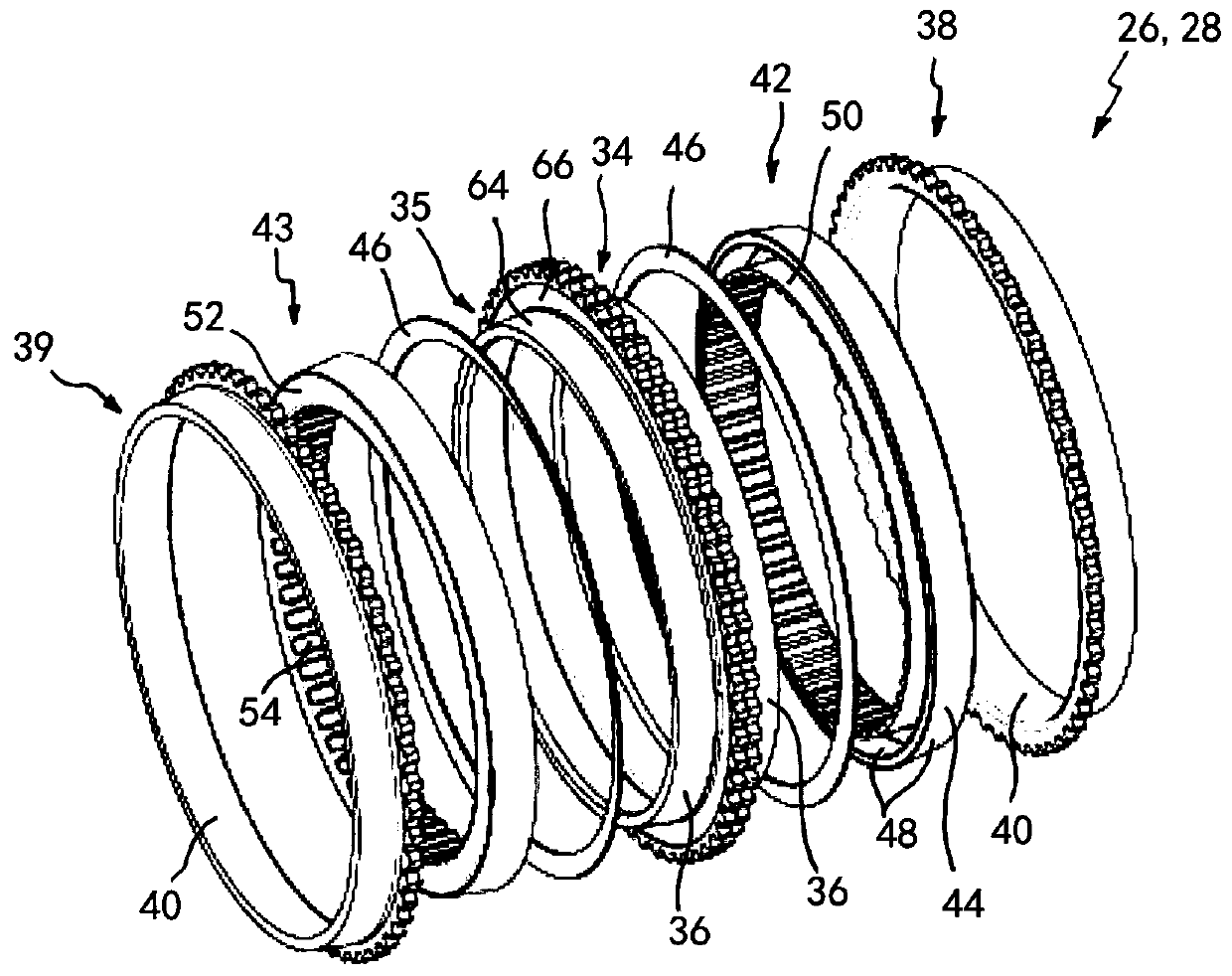

[0049] figure 1 An electro-hydraulic actuated, fully automatic stepped transmission 10 of a motor vehicle is shown, which includes a torque converter 12, four planetary transmissions or planetary gear sets 14, and a transmission housing 16 shown schematically. In addition, a drive shaft 18, a driven shaft 20 and a plurality of transmission shafts are also provided, and the planet carrier is also referred to as a transmission shaft in the following content. The transmission shafts are allocated to the respective planetary gear sets 14 and are arranged coaxially with each other.

[0050] The stepped transmission 10 further includes shifting devices 26, 28, which can be applied to hydraulic pressure, and can couple the transmission shaft to another transmission shaft or the transmission housing 16, or connect the transmission shaft to the further transmission shaft Or the transmission housing 16 is separated.

[0051] The shifting device 26 that couples the transmission shaft to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com