A printing platform of an inkjet printing device

A technology of inkjet printing equipment and printing platform, applied in printing devices, printing and other directions, can solve problems such as affecting the printing image quality, scrapping, scratching the print head screen, etc., and achieve the effect of ensuring long-term stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Below in conjunction with accompanying drawing, the present invention is further described:

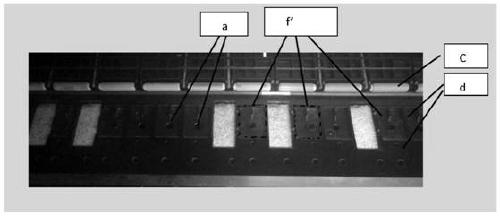

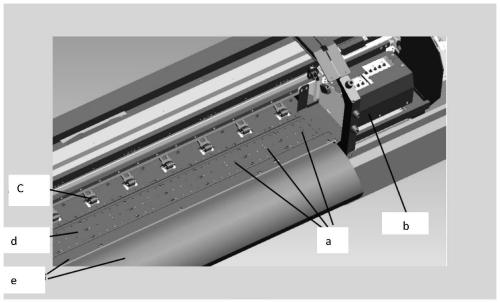

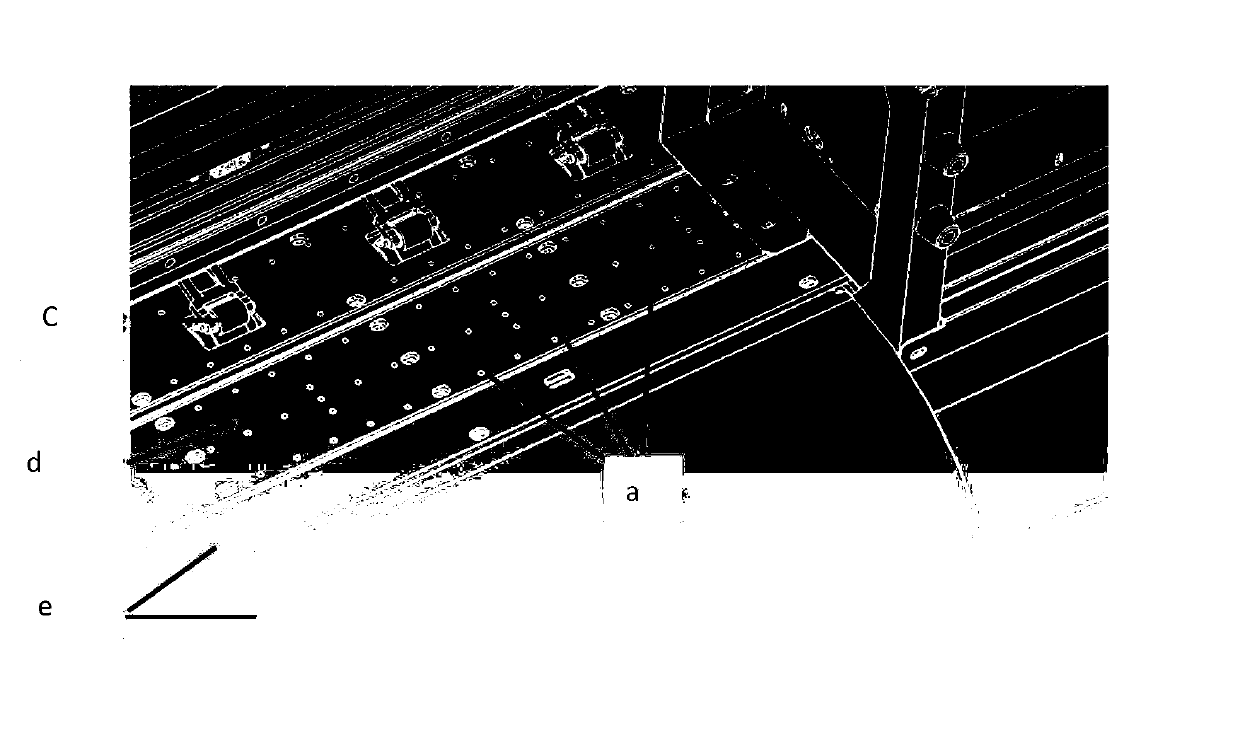

[0064] Figure 1-Figure 6 Shown is the situation of the printer in the prior art, figure 1 It is a three-dimensional rendering of the printing platform of a conventional printing device. figure 2 It is a three-dimensional wireframe diagram of the printing platform of a conventional printing device. image 3 It is a printing equipment platform with groove design on the market. Figure 4 It is a printing equipment platform with a suction pool on the market. Figure 5 It is a measured photo of the swelling and wrinkling of the printing platform. Figure 6 It is another measured photo of the swelling and wrinkling of the printing platform.

[0065] A printing platform structure, including vertical raised planes with a certain width, which are evenly distributed in the X direction of the entire platform (that is, the printing width direction); at the same time, concave planes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com