Enclosed nose for butt welding of high-temperature fused salt collector tubes

A technology of high-temperature molten salt and heat-collecting tubes, which is applied in applications, household appliances, welding equipment, etc., can solve the problems of butt welding of stainless steel high-temperature molten-salt heat-collecting tubes with a thickness of 3 mm, increased welding difficulty and welding costs, and weld assembly gaps Higher requirements and other issues, to achieve the effect of improving welding operation efficiency, simple structure, convenient maintenance and testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

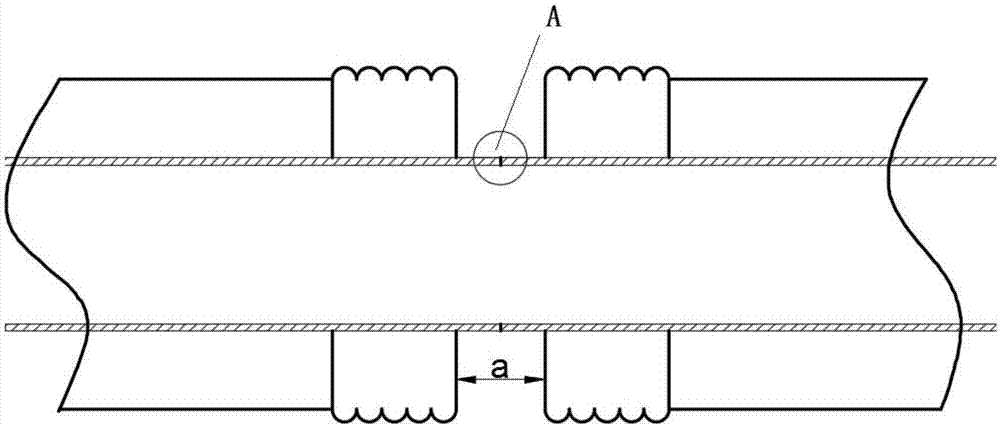

[0033] Attached below Figures 1 to 4 The present invention will be further described in detail with specific embodiments. It should be noted that: the following examples are illustrative, not restrictive, and the protection scope of the present invention cannot be limited by the following examples.

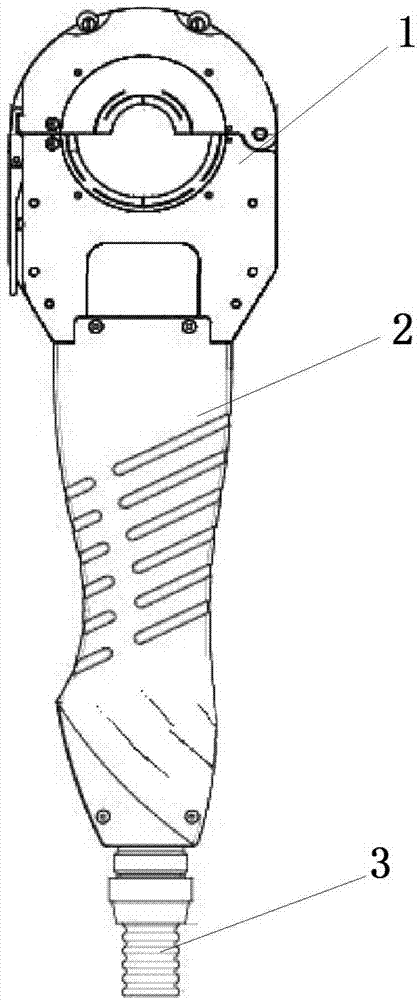

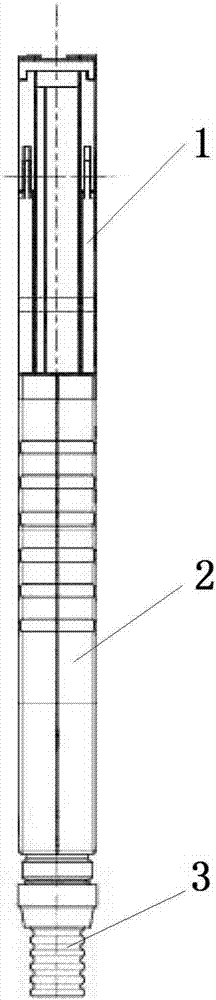

[0034] A closed head for butt welding of high-temperature molten salt heat collecting tubes, including an insulating body 1, a handle 2 and a wire harness 3; the thickness of the insulating body 1 is 20mm, including a top cover, an inner core and a shell, and the The top cover is set opposite to the shell and forms a through hole through which the high-temperature molten salt heat collecting tube can pass axially. One end of the top cover is fixed on one side of the shell and can be opened and closed with the fixed point as the axis. The angle is 180°; the other end is movably connected to the housing through a pin shaft; the inner core is arranged inside the housing, and the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com