Plane bending forming clamping device and die with clamping device

A clamping device and plane technology, which is applied in the field of clamping devices for flat bending of copper bars, can solve the problems of difficulty in ensuring the quality of molding, cumbersome installation and disassembly procedures, and poor quality stability of molded parts, achieving simple structure, Guaranteed surface smoothness, easy construction and portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

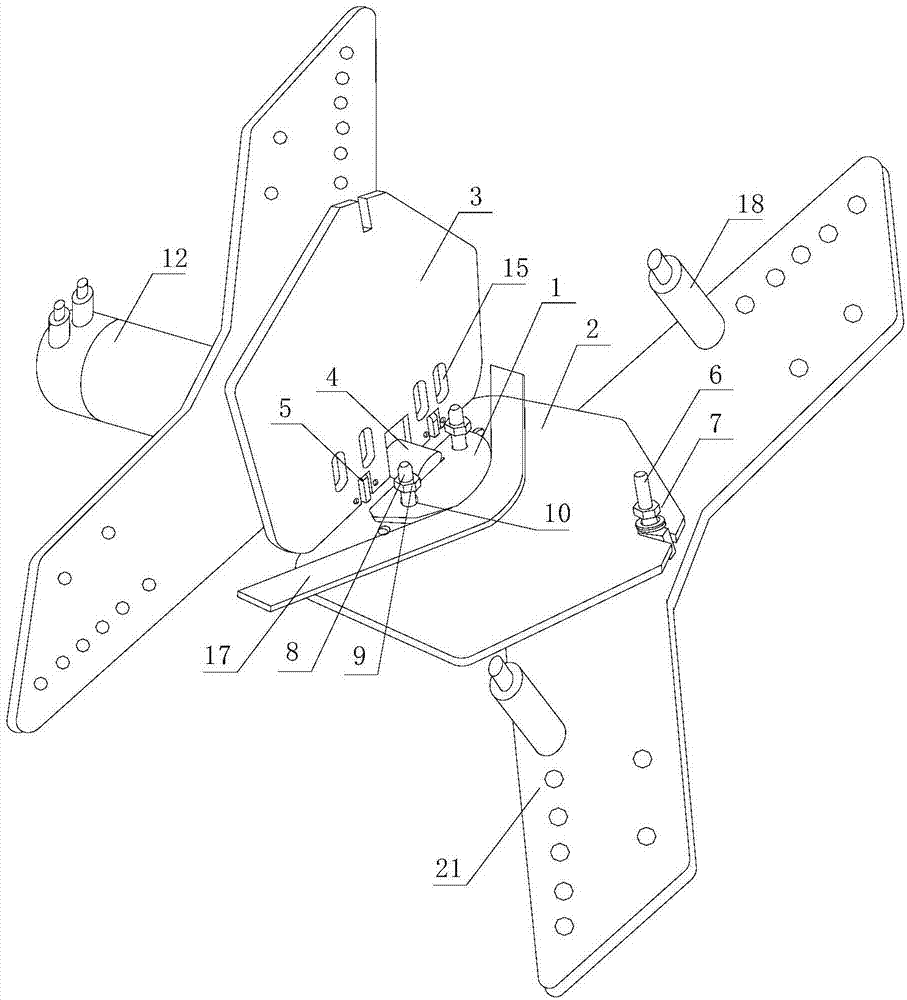

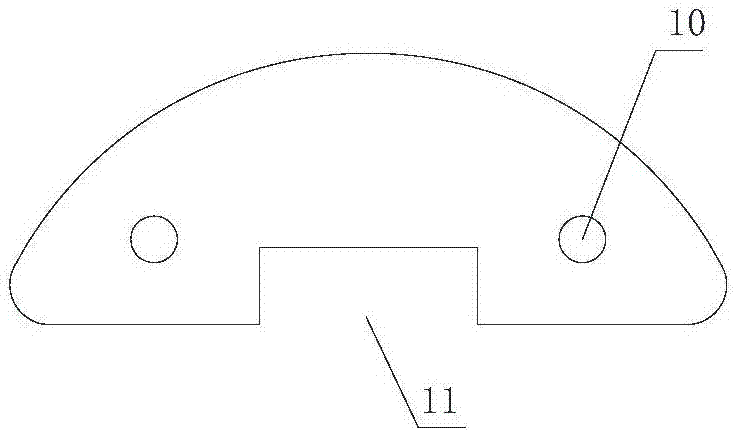

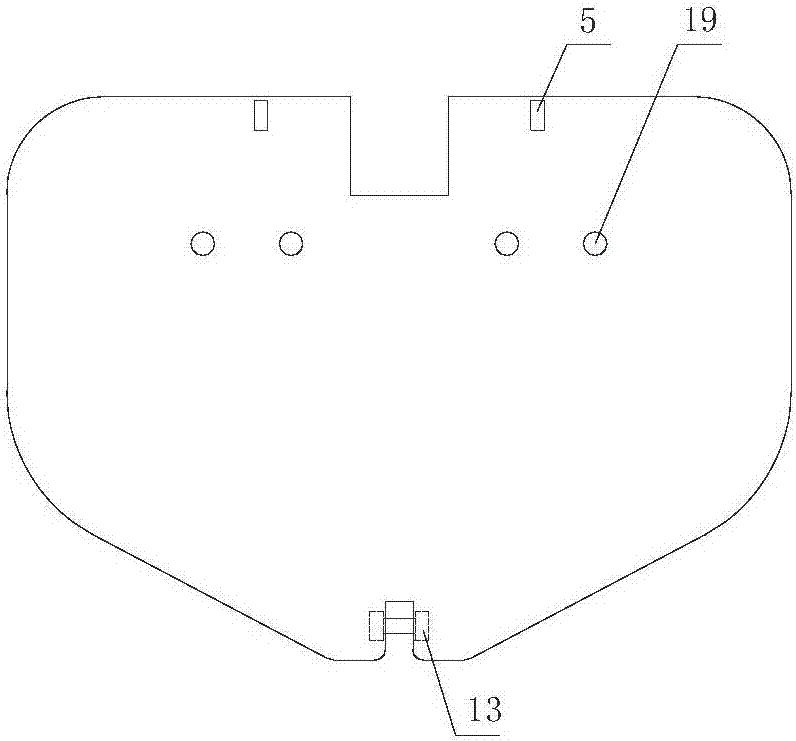

[0054] Such as Figure 1 to Figure 10 As shown, the first choice is to place the clamping device (20) in the hydraulic pipe bender (12), insert the hydraulic rod into the sinking groove of the sleeve head 4, select the appropriate angle forming module 1 according to the raw material specification, and form the mold according to the angle Positioning hole (10) of part 1, fix the angle forming module 1 on the first splint 2, the positioning bolt on the first splint 2 passes through the positioning hole (10) of the angle forming module 1, delineate on the raw material The position of the inflection point is placed flat on the first splint 2, the inflection point is aligned with the center of the angle forming module 1, and the second splint 3 is closed so that the positioning screw 8 passes through the positioning screw 8 holes on the second splint 3, and at the same time Set the positioning screw nut (9) on the positioning screw 8, use the first clamping plate 2 and the second c...

Embodiment 2

[0056] The difference between this embodiment and the above-mentioned first embodiment is that the angle forming module 1 is located on the side away from the connector of the first splint 2, the sleeve 4 is still welded on the first splint 2, and the forming part (17) is against Hold the support (18), the hydraulic pipe bender (12) starts, the hydraulic rod is inserted into the sleeve 4, and the hydraulic rod drives the entire clamp to move forward until the formed part (17) is between the support (18) and the hydraulic pipe bender ( 12) Under the action of plane bending molding.

Embodiment 3

[0058] The difference between this embodiment and the first embodiment above is that there are two locking devices, which are symmetrically arranged on both sides of the first splint 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com