Super-hydrophobic and superoleophilic metal nickel net as well as preparation method and application thereof

A super-oleophilic and super-hydrophobic technology, applied in separation methods, chemical instruments and methods, and separation of immiscible liquids, can solve problems such as high cost, poor durability, and complex manufacturing process of super-hydrophobic and super-oleophilic membrane materials, and achieve The effect of small rolling angle, good durability, and good recyclability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

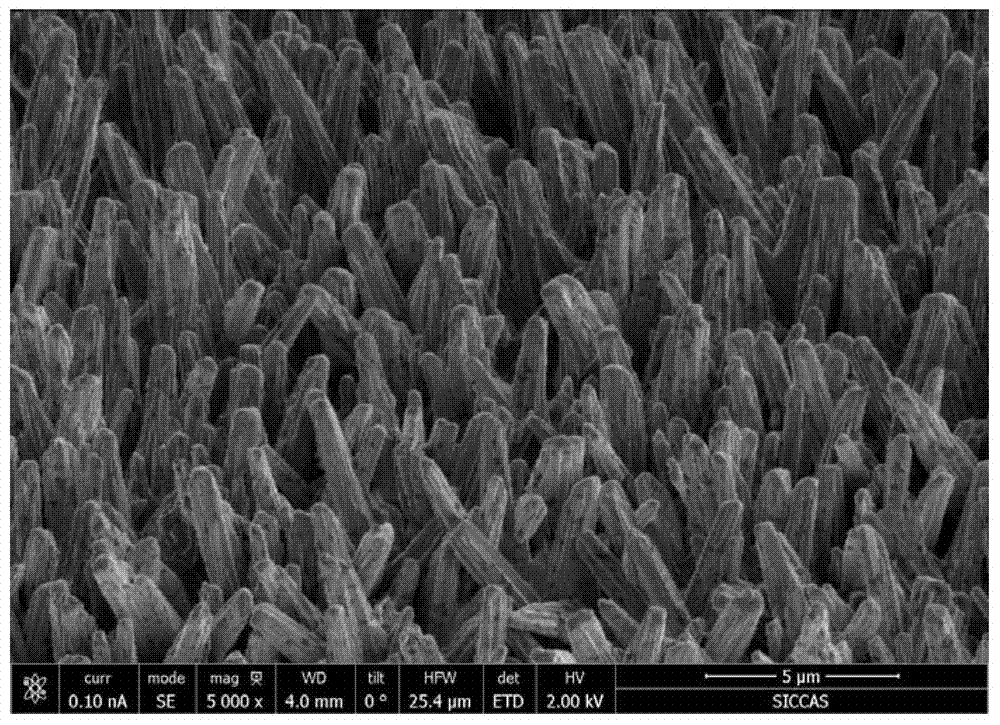

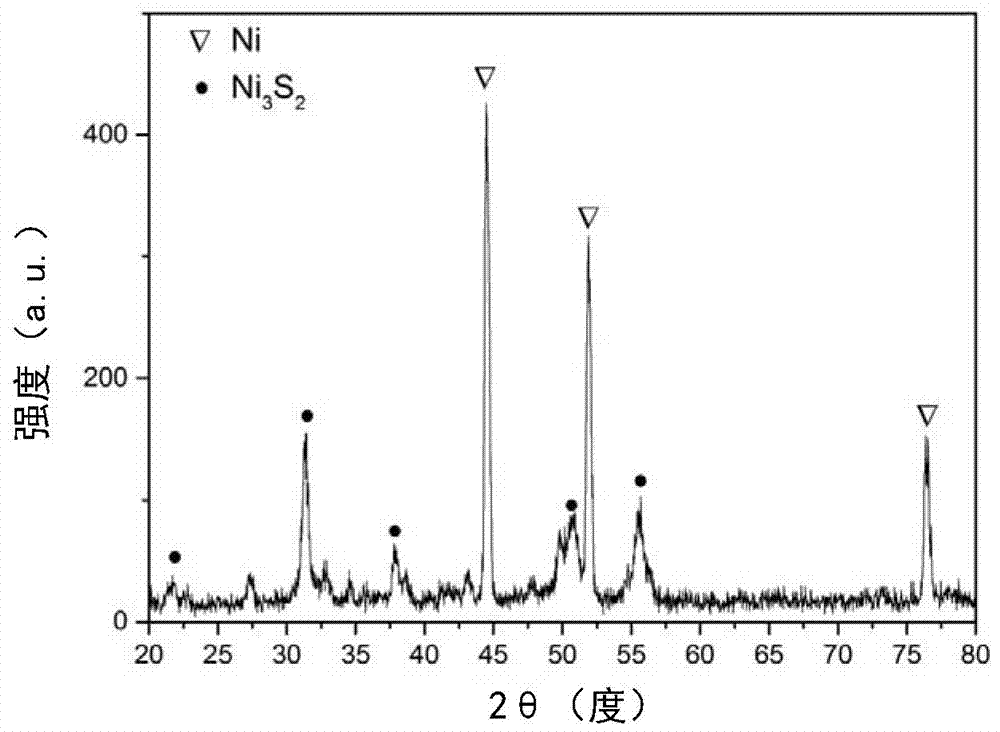

[0046] A nickel mesh sample with a diameter of 4 cm (mass 0.65 g) was ultrasonicated in acetone, ethanol, and pure water for 10 minutes, washed with pure water and dried in an oven at 50°C for 2 hours; then immersed in 3M HCl solution for 2 After taking it out, wash it with pure water and dry it in an oven at 50°C for 2 hours; then soak it in 70 ml of thiourea solution with a concentration of 13.8%, and conduct a closed hydrothermal reaction at 180°C for 6 hours, take it out, wash it with pure water, and then It was dried in an oven at 50°C for 2 hours; then the sample was immersed in a 0.1% ethanol solution of octadecanethiol (50 ml) for 24 hours, taken out and washed with ethanol and dried in an oven at 50°C for 2 hours. Finally, the Ni used in this experiment was obtained 3 S 2 Superhydrophobic superoleophilic nickel mesh. figure 1 for the resulting Ni 3 S 2 SEM photographs of superhydrophobic superoleophilic nickel mesh, visible, Ni 3 S 2 It is rod-shaped, with a dia...

Embodiment 2

[0050] A nickel mesh sample (0.63g) with a diameter of 4 cm was ultrasonicated in acetone, ethanol and pure water for 10 minutes, washed with pure water and dried in an oven at 50°C for 2 hours; then immersed in 3M HCl solution for 2 hours, After taking it out, wash it with pure water and dry it in an oven at 50°C for 2 hours; then immerse it in a thiourea solution (70 ml) with a concentration of 13.8%, and conduct a closed hydrothermal reaction at 180°C for 12 hours. After taking it out, wash it with pure water and put it on Dry in an oven at 50°C for 2 hours; then put the sample in 0.1% stearyl mercaptan ethanol solution (50 ml) for 12 hours, take it out and wash it with ethanol and dry it in an oven at 50°C for 2 hours. Finally, the Ni used in this experiment was obtained 3 S 2 Superhydrophobic superoleophilic nickel mesh. Through measurement, the contact angle reached 150°, and the rolling angle was about 13°, showing good superhydrophobic performance. The Ni 3 S 2 Th...

Embodiment 3

[0053] A nickel mesh sample (0.65 g) with a diameter of 4 cm was ultrasonicated in acetone, ethanol and pure water for 10 minutes, washed with pure water and dried in an oven at 50 °C for 2 hours; then immersed in 3M HCl solution for 2 hours, After taking it out, wash it with pure water and dry it in an oven at 50°C for 2 hours; then immerse it in a mixed solution of ammonium molybdate and thiourea (70 ml), in which the mass concentration of ammonium molybdate is 15%, and the concentration of thiourea is 40%. Hydrothermal reaction at 230°C for 24 hours, take it out, wash it with pure water, and dry it in an oven at 50°C for 2 hours; then put the sample in 0.1% stearyl mercaptan ethanol solution (50 ml) for 24 hours, take it out After washing with ethanol, dry in an oven at 50°C for 2 hours. Finally, the superhydrophobic superlipophilic MoS used in this experiment was obtained 2 -Ni 3 S 2 Finished nickel mesh. Figure 4 For its SEM photo, it can be seen that MoS 2 and Ni ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com