Calcium phosphate biological bone cement composite material reinforced by carbon nanotube and graphene

A technology of composite materials and carbon nanotubes, which is applied in the intersecting fields of materials science and biomedicine, can solve the problems of low strength, lack of solutions, poor toughness, etc., and achieve improved strength, good strength and biocompatibility, and shortened coagulation the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The ratio of the calcium phosphate bio-bone cement composite material is (wt%): α-tricalcium phosphate 94.8%, hydroxyapatite 5%, graphene 0-1%, carbon nanotube 0%.

[0042]First, weigh a certain amount of α-tricalcium phosphate, hydroxyapatite and graphene according to the proportion, place them in a ball mill jar, mill them at 400r / min for 5 hours, and pass through a 300-mesh sieve to obtain a calcium phosphate bio-bone cement composite. Material Raw material powder. Then the raw material powder and distilled water are mixed uniformly at 0.35ml / g, and placed in an environment with a temperature of 37° C. and a humidity of 100% to condense it. This process does not require microwave treatment. After 24 hours, a fully coagulated calcium phosphate biocement composite material was obtained.

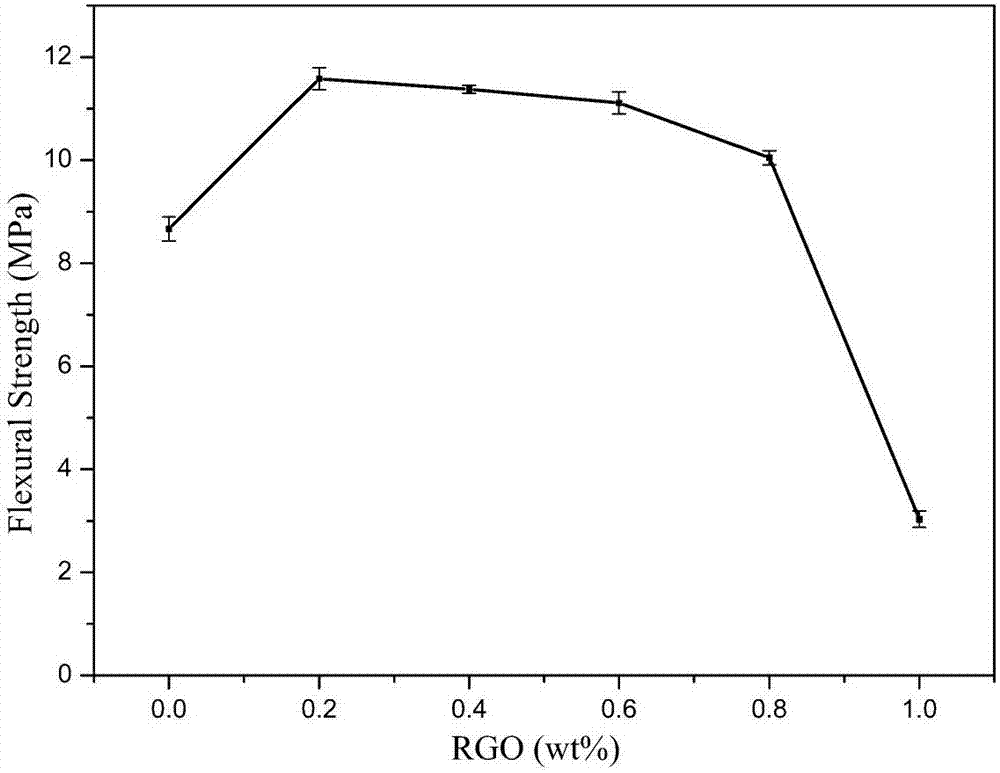

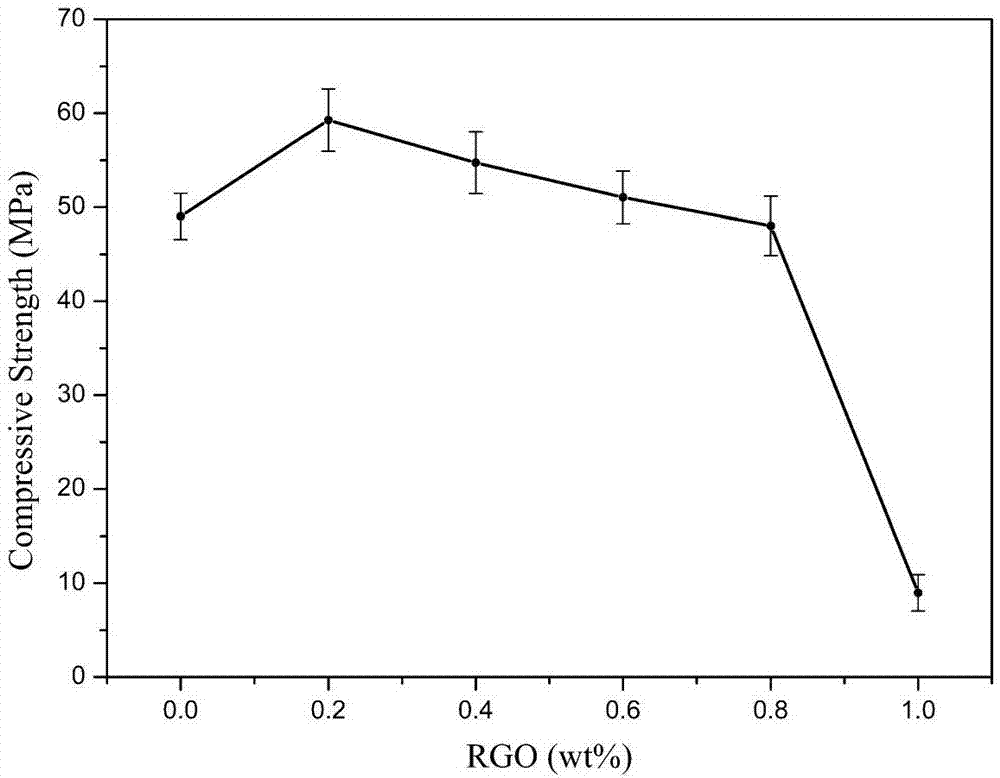

[0043] The maximum flexural strength of the calcium phosphate bio-bone cement composite material reaches 11.6±0.2MPa, see figure 1 , the highest compressive strength reaches 59.3±3....

Embodiment 2

[0045] The ratio of the calcium phosphate bio-bone cement composite material is (wt%): α-tricalcium phosphate 94.2%, hydroxyapatite 5%, graphene 0.2%, and carbon nanotube 0.2-1%.

[0046] First, weigh a certain amount of α-tricalcium phosphate, hydroxyapatite and graphene according to the proportion, place them in a ball mill jar, mill them at 400r / min for 5 hours, and pass through a 300-mesh sieve to obtain a calcium phosphate bio-bone cement composite. Material Raw material powder. Then the raw material powder and distilled water are mixed uniformly at 0.35ml / g, and placed in an environment with a temperature of 37° C. and a humidity of 100% to condense it. This process does not require microwave treatment. After 24 hours, a fully coagulated calcium phosphate biocement composite material was obtained.

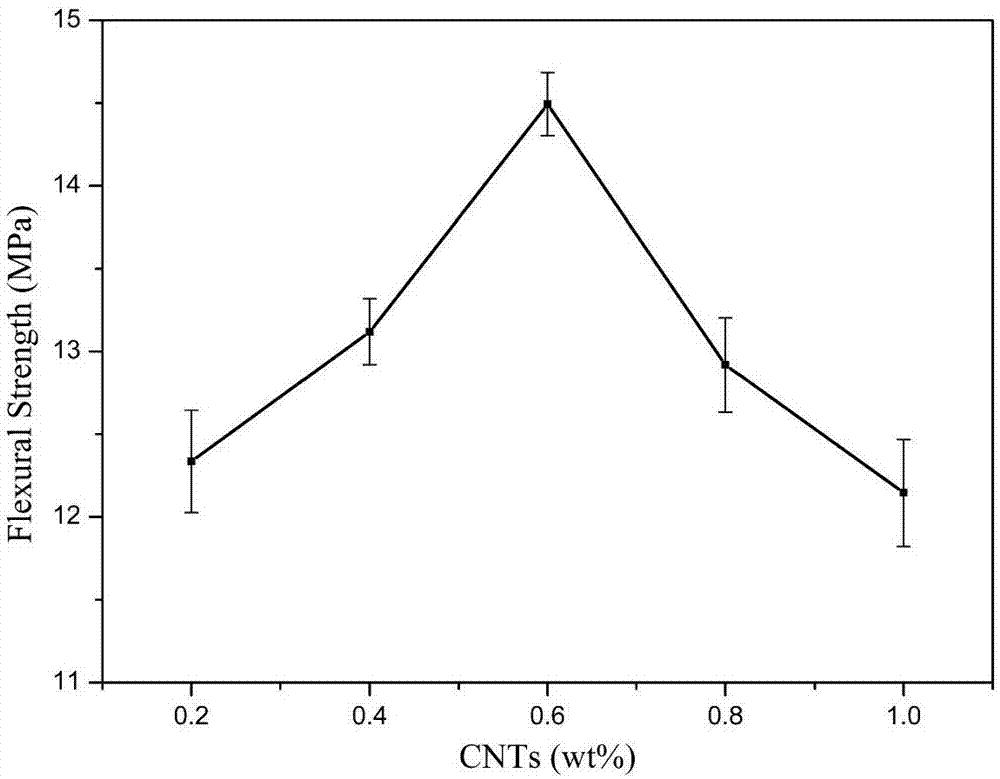

[0047] The flexural strength of the calcium phosphate bio-bone cement composite material can reach 14.5±0.2MPa, see image 3 , the compressive strength can reach 86.5±2.7MP...

Embodiment 3

[0049] The ratio of the calcium phosphate bio-bone cement composite material is (wt%): α-tricalcium phosphate 94.2%, hydroxyapatite 5%, graphene 0.2%, and carbon nanotube 0.2-1%.

[0050] First, weigh a certain amount of α-tricalcium phosphate, hydroxyapatite and graphene according to the proportion, place them in a ball mill jar, mill them at 400r / min for 5 hours, and pass through a 300-mesh sieve to obtain a calcium phosphate bio-bone cement composite. Material Raw material powder. Then mix the raw material powder and distilled water evenly at 0.35ml / g, place it in an environment with a temperature of 37°C and a humidity of 100% to coagulate it. This process continues to be treated with microwaves before the final coagulation. 4h Microwave treatment for half an hour. After 24 hours, a fully coagulated calcium phosphate biocement composite material was obtained.

[0051] The flexural strength of the calcium phosphate bio-bone cement composite material can reach 17.4±0.2MPa,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com