Image module structure

An image module and image sensor technology, which is applied in image communication, television, color television, etc., can solve the problems of optical axis offset, unsuitable for miniaturized devices, and optical axis alignment, etc., so as to improve quality and improve The effect of difficult alignment and easy alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

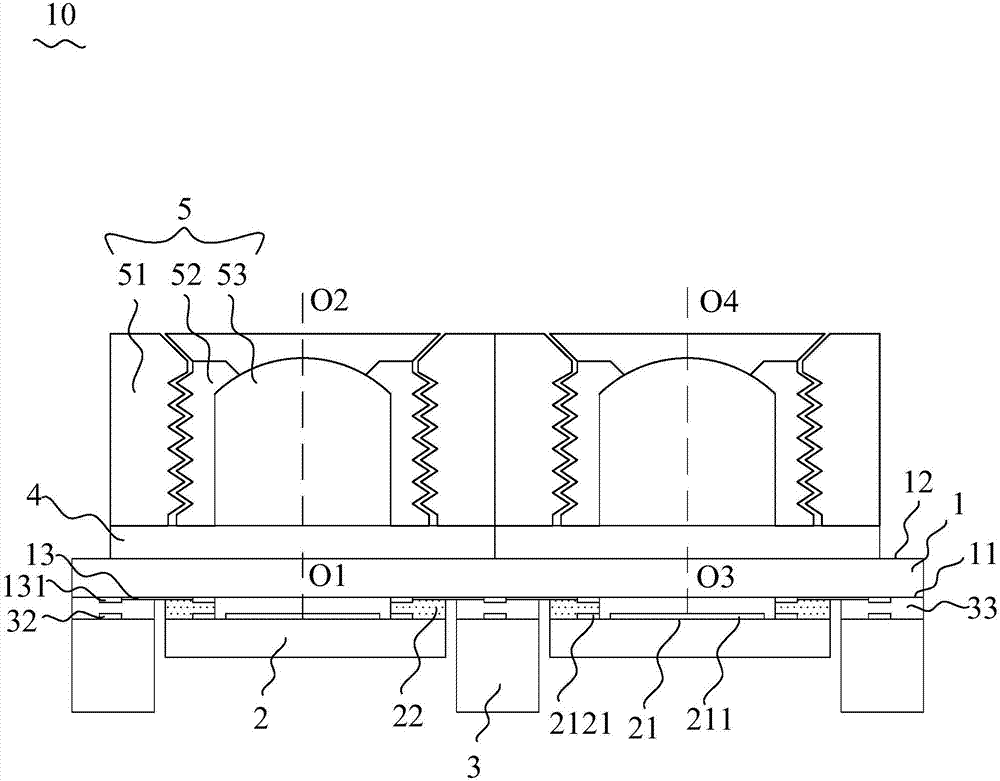

[0019] In order to describe the technical content, structural features, purpose and effect of the present invention in detail, the following examples are given together with the drawings to describe in detail.

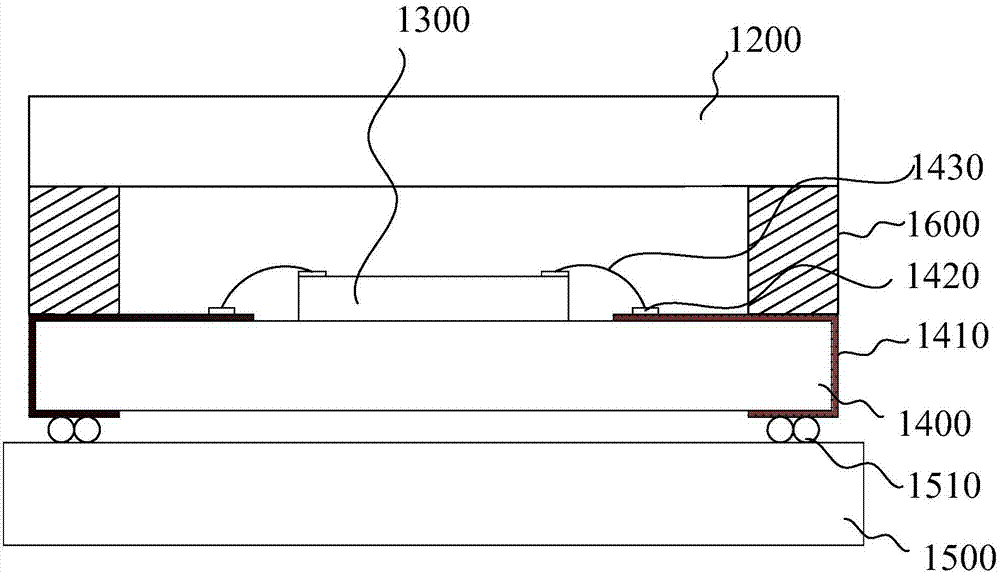

[0020] see figure 2 as shown, figure 2 As an embodiment of the present invention, an image module structure 10 includes a glass substrate 1 , a plurality of image sensors 2 , a circuit board 3 , a carrier pad 4 , and a lens device 5 .

[0021] In this embodiment, the design of two lens devices 5 is used as a schematic diagram of the present invention. Wherein, the glass substrate 1 has a first surface 11 and a second surface 12 , and a plurality of image sensors 2 are disposed on the first surface 11 . The circuit board 3 is also arranged on the first surface 11, and has a plurality of hollow blocks 31 and a conductive area 32. The conductive area 32 is adjacent to the hollow blocks 31 and faces the glass substrate 1. Each hollow block 31 Corresponding to the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com