Heavy oil well shaft viscosity reduction test device

A testing device and wellbore technology, applied in the direction of measurement device, DC flow characteristic measurement, flow characteristic, etc., can solve the problems of low accuracy and reliability, lack of theoretical basis, etc., achieve simple structure, high degree of simulation, improve field The effect of applying the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

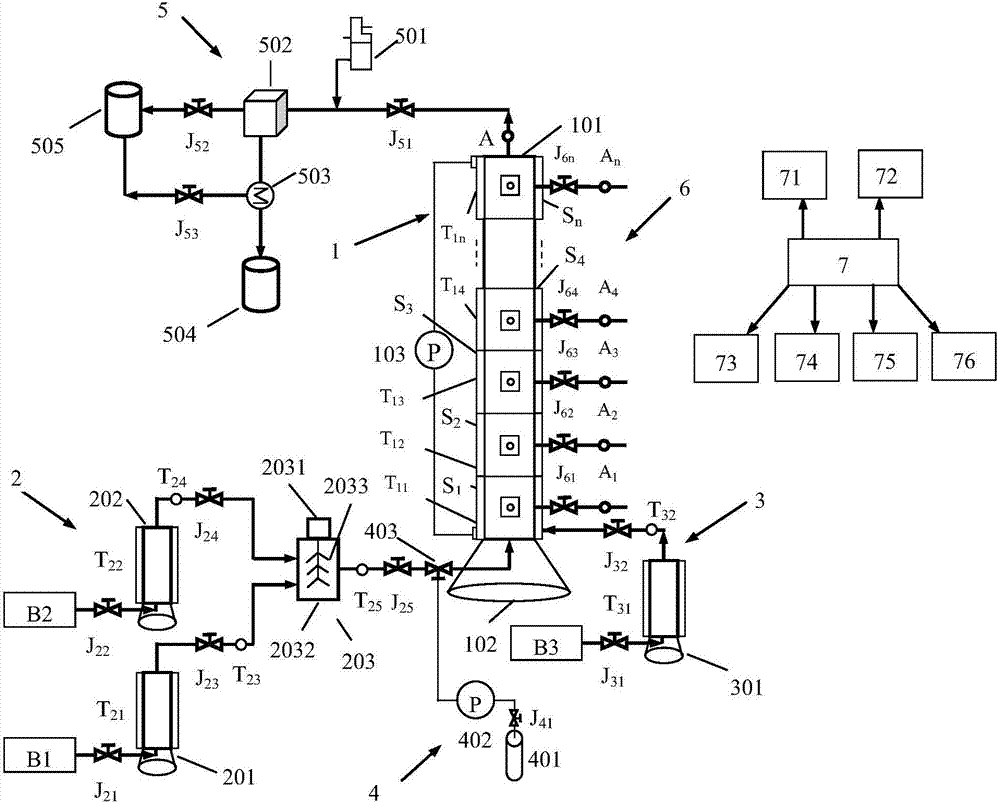

[0024] like figure 1As shown, a heavy oil well wellbore viscosity reduction test device provided by the present invention includes a simulated wellbore unit 1, an oil and water injection unit 2, a viscosity reducer dosing unit 3, a reservoir pressure simulation unit 4, produced fluid treatment and Recovery unit 5, viscosity online testing unit 6 and control unit 7. The oil and water injection unit 2 and the reservoir pressure simulation unit 4 are connected to the bottom of the simulated wellbore unit 1 through a high-pressure pipeline, and the viscosity reducer dosing unit 3 is connected to the bottom of the side wall of the simulated wellbore unit 1 through a high-pressure pipeline. The liquid treatment and recovery unit 5 is connected to the top of the simulated wellbore unit 1 through a high-pressure pipeline, and the viscosity online testing unit 6 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com