Full-automatic cloth cutting device

A fully automatic, cloth feeding device technology, applied in the cutting of textile materials, textile and paper making, metal processing, etc., can solve the problems of inconvenient use, achieve the effect of less labor consumption, increase driving force, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

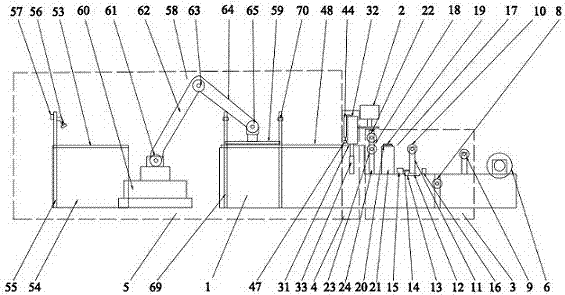

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

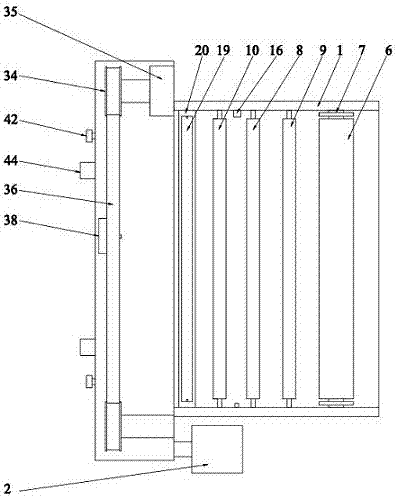

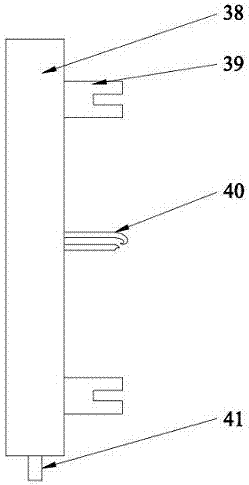

[0019] A fully automatic cloth cutting device, comprising a frame 1 and a power distribution console 2, the frame 1 is provided with a cloth feeding device 3, a cloth cutting device 4 and a cloth receiving device 5, and the front end of the cloth feeding device 3 is provided with a raw material roller 6. It is characterized in that: the two ends of the raw material drum 6 are connected to the frame 1 through the supporting shaft and the bearing, and the supporting shafts at the two ends of the raw material drum 6 are respectively covered with magnetic powder brakes 7, and the magnetic powder brakes 7 are connected to the power distribution console 2. Connection, magnetic powder brakes, such as YSB series magnetic powder brakes, have the advantages of fast response, simple structure, no pollution, no noise, no impact vibration, energy saving, etc., which can effectively p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com