Device and method for hot charging rotary hearth furnace direct-reduced pellets into furnaces

A rotary hearth furnace and pelletizing technology, applied in hearth furnaces, furnaces, furnace types, etc., can solve the problems of difficult overhead, complicated civil construction, huge costs, etc., achieve a high degree of automation, improve economic benefits, and reduce comprehensive energy. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

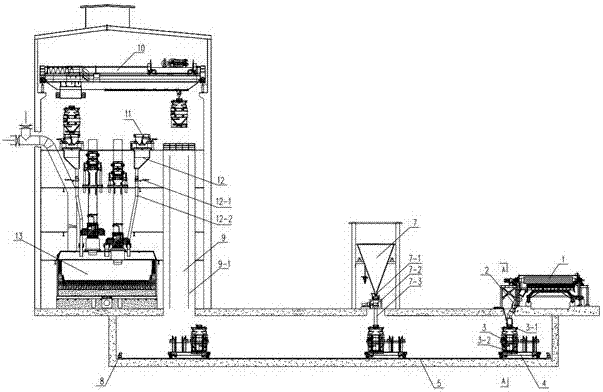

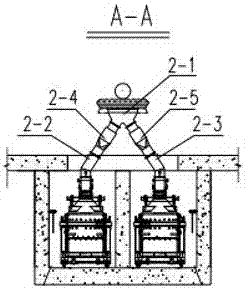

[0024] Embodiment: A kind of device of rotary hearth furnace direct reduction pellet hot charging furnace, such as figure 1 , 2 As shown, it includes rotary hearth furnace 1, discharge chute 2, closed material tank 3, carrier vehicle 4, transport track 5, batching bin 7, positioning sensor 8, lifting shaft 9, bridge crane 10, material bell 11, furnace Bottom material bin 12, submerged arc furnace 13.

[0025] In this embodiment, two parallel transport rails 5 are set, and each rail 5 corresponds to a reciprocating transport vehicle 4 , and each transport vehicle 4 is provided with two loading positions for airtight material tanks 3 . The airtight material tank 3 can keep the pellets warm, and the upper and lower sides are respectively equipped with a material receiving port 3-1 and a material discharging port 3-2. Automatically turns on and turns off automatically when you leave. During the transportation and lifting process of the material tank 3, the discharge port 3-2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com