A kind of microbial strain and its application in cocoon silk degumming

A technology of microorganisms and cocoons, applied in microbial strains and its application fields, can solve the problems of high cost of enzyme refining, long production cycle, poor working environment, etc., and achieve the effect of simple operation method, environmentally friendly production process and mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

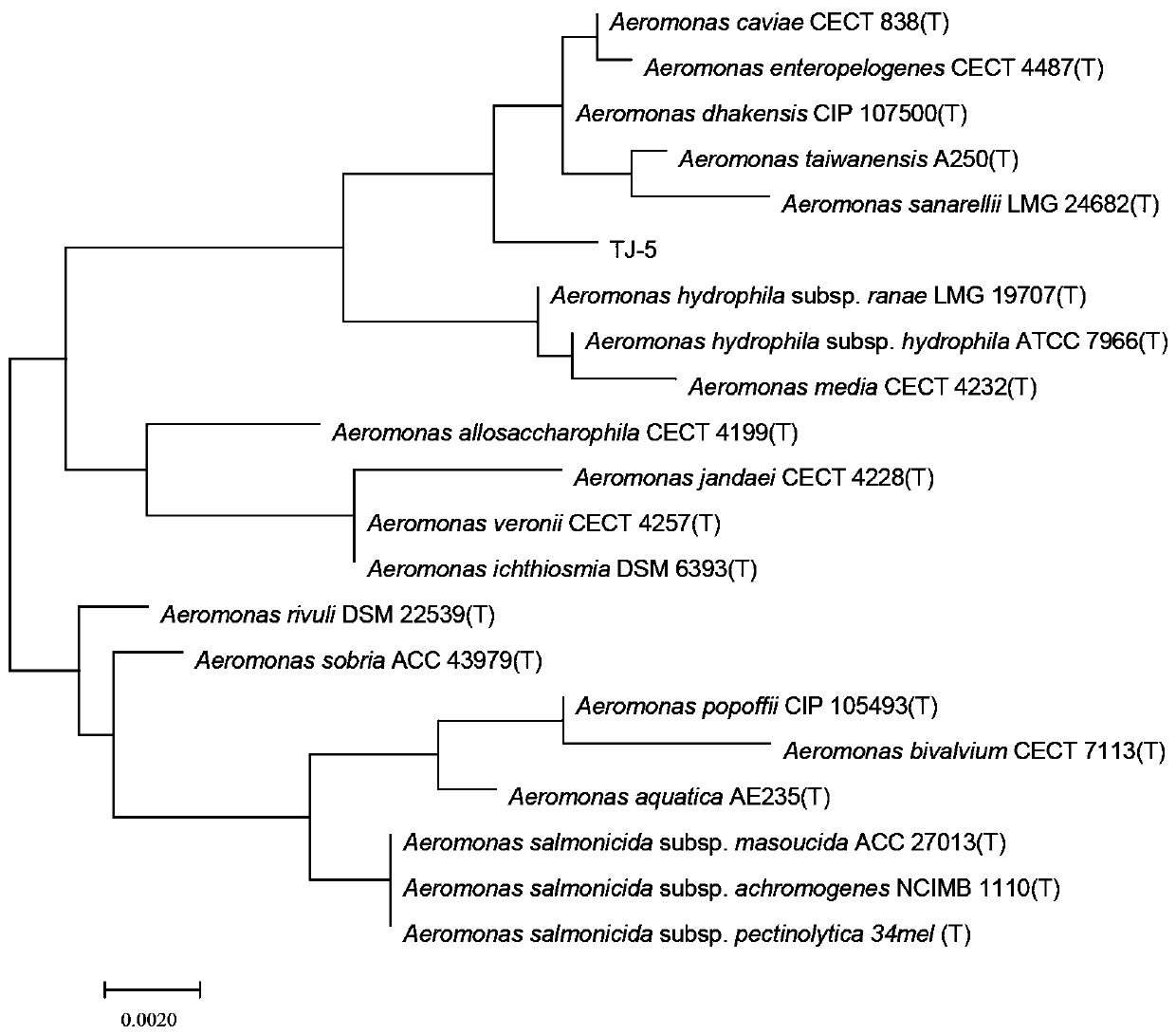

[0026] A microbial strain that can be used for cocoon silk degumming is Aeromonas, with a Latin literary name of Aeromonassp.TJ-5. The microorganism was preserved in the China Center for Type Culture Collection on April 14, 2017, and the preservation number is CCTCCNO :M2017192.

Embodiment 2

[0028] The screening method of microbial strain Aeromonas sp.TJ-5, comprises the following steps:

[0029] (1) Add 10mL of cocoon silk decomposing liquid obtained by sampling into 90mL of seed medium prepared as follows: 10g / L tryptone, 5g / L yeast extract, and 5g / L NaCl, pH 7.0; then placed on a shaker at 37°C, shaken at 180rpm for 12 hours to obtain a bacterial suspension;

[0030] (3) Dilute the above-mentioned cultured bacterial suspension to different times and spread it on the seed liquid agar plate, and cultivate it at 37°C for 24 hours;

[0031] (4) Pick a single colony and inoculate it into the degumming medium. The degumming medium is prepared as follows: 3g / L ammonium nitrate; 0.5g / L potassium dihydrogen phosphate; 1.5g / L disodium hydrogen phosphate, 1g / L NaCl , 0.2g / L magnesium sulfate heptahydrate; pH 7.0, then add 0.5g cocoon silk, then shake and culture at 37°C and 180rpm for 48h.

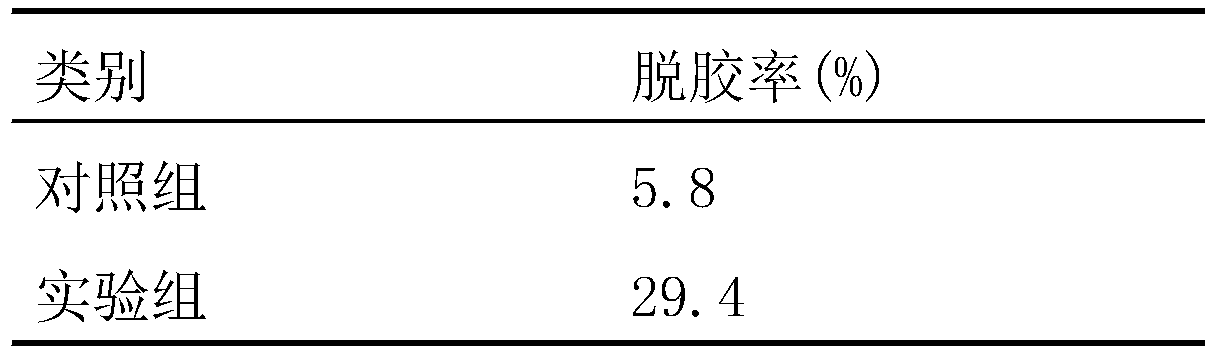

[0032] (5) Measure and calculate cocoon degumming rate.

[0033] After the deg...

Embodiment 3

[0039] Microbial strain Aeromonas Aeromonassp.TJ-5 can be applied to remove sericin in cocoon silk. The specific cocoon silk degumming application includes the following steps:

[0040] (1) preparation of degumming microorganisms;

[0041] (2) cocoon silk microbial degumming treatment;

[0042] (3) Water washing: after the degumming is finished, take out the cocoon silk and wash it with water;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com