A kind of room temperature binding preparation method of powder coating

A powder coating and binding technology, applied in powder coating, polyester coating, coating, etc., can solve the problems of high scrap rate, wrong binding, pre-curing, etc., to reduce the binding temperature, avoid high scrap rate, Guaranteed the effect of gloss and flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. The preparation mass fraction is 100g of polyvinyl alcohol (PVA1788) solution of 2%;

[0031] 2. Prepare a borax solution with a mass fraction of 5%, take 1 g of the borax solution, slowly add it to the stirring polyvinyl alcohol solution (prepared in step 1), and continue stirring for 10 minutes at a stirring speed of 2000 rpm;

[0032] 3. Mix metal aluminum powder, artificial zeolite powder with a particle size of 1-2 microns, and the solution obtained in step 2 in a mass ratio of 3:1:6 in a mixer at a low speed for 30 seconds at a stirring speed of 300 rpm to prepare a metal powder wet material mixture ;

[0033] 4. Stir the polyester-TGIC powder coating base material and the metal powder wet material mixture obtained in step 3 at a mass ratio of 97:10 in a mixer at a low speed for 60 seconds at a stirring speed of 200 rpm;

[0034] 5. The mixture obtained in step 4 is dispersed and dried instantly with an airflow mixer at an air pressure of 0.1 MPa, and the boun...

Embodiment 2

[0038] 1. The preparation mass fraction is 100g of polyvinyl alcohol (PVA 1799) solution;

[0039] 2. Prepare a borax solution with a mass fraction of 10%, take 1 g of the borax solution, slowly add it to the stirring polyvinyl alcohol solution (prepared in step 1), and continue stirring for 10 minutes at a stirring speed of 2000 rpm;

[0040] 3. Mix metal aluminum powder, artificial zeolite powder with a particle size of 1-2 microns, and the solution obtained in step 2 in a mass ratio of 4:1:6 in a mixer at a low speed for 60 seconds at a stirring speed of 300 rpm to prepare a metal powder wet material mixture ;

[0041] 4. Stir the polyester-TGIC powder coating base material and the metal powder wet material mixture obtained in step 3 at a mass ratio of 96:11 in a mixer for 60 seconds at a low speed, and the stirring speed is 200rpm;

[0042] 5. The mixture obtained in step 4 is dispersed and dried instantly with an airflow mixer at an air pressure of 0.1 MPa, and the bound...

Embodiment 3

[0046] 1. The mixture obtained in steps 1-4 in Example 1 was mixed with a high-shear mixer (rotating speed 2000r / min) for 1 minute, and then naturally volatilized and dried in the air for 5 hours to obtain a bound product;

[0047] 2. The prepared bound products were scanned by electron microscope and sprayed on board respectively.

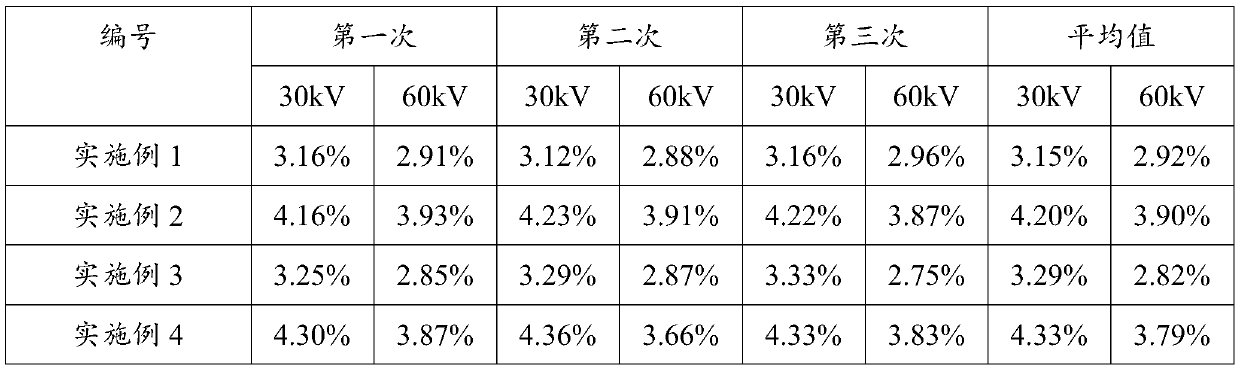

[0048] The metal powder is well bound to the powder coating particles; when the spraying voltage is 30kV and 90kV respectively, the measured metal powder content in the upper plate powder is 3.29% and 2.82%, which is different from the original addition of 3.00% metal powder The quantity is basically the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com