Normal-temperature binding preparation method of powder coating

A powder coating and binding technology, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of high scrap rate, wrong binding, high cost, etc., to reduce binding temperature, avoid high scrap rate, The effect of simplifying the binding operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. The preparation mass fraction is 100g of polyvinyl alcohol (PVA1788) solution of 2%;

[0031] 2. Prepare a borax solution with a mass fraction of 5%, take 1 g of the borax solution, slowly add it to the stirring polyvinyl alcohol solution (prepared in step 1), and continue stirring for 10 minutes at a stirring speed of 2000 rpm;

[0032] 3. Mix metal aluminum powder, artificial zeolite powder with a particle size of 1-2 microns, and the solution obtained in step 2 in a mass ratio of 3:1:6 in a mixer at a low speed for 30 seconds at a stirring speed of 300 rpm to prepare a metal powder wet material mixture ;

[0033] 4. Stir the polyester-TGIC powder coating base material and the metal powder wet material mixture obtained in step 3 at a mass ratio of 97:10 in a mixer at a low speed for 60 seconds at a stirring speed of 200 rpm;

[0034] 5. The mixture obtained in step 4 is dispersed and dried instantly with an airflow mixer at an air pressure of 0.1 MPa, and the boun...

Embodiment 2

[0038] 1. The preparation mass fraction is 100g of polyvinyl alcohol (PVA 1799) solution;

[0039] 2. Prepare a borax solution with a mass fraction of 10%, take 1 g of the borax solution, slowly add it to the stirring polyvinyl alcohol solution (prepared in step 1), and continue stirring for 10 minutes at a stirring speed of 2000 rpm;

[0040] 3. Mix metal aluminum powder, artificial zeolite powder with a particle size of 1-2 microns, and the solution obtained in step 2 in a mass ratio of 4:1:6 in a mixer at a low speed for 60 seconds at a stirring speed of 300 rpm to prepare a metal powder wet material mixture ;

[0041] 4. Stir the polyester-TGIC powder coating base material and the metal powder wet material mixture obtained in step 3 at a mass ratio of 96:11 in a mixer for 60 seconds at a low speed, and the stirring speed is 200rpm;

[0042] 5. The mixture obtained in step 4 is dispersed and dried instantly with an airflow mixer at an air pressure of 0.1 MPa, and the bound...

Embodiment 3

[0046] 1. The mixture obtained in steps 1-4 in Example 1 was mixed with a high-shear mixer (rotating speed 2000r / min) for 1 minute, and then naturally volatilized and dried in the air for 5 hours to obtain a bound product;

[0047] 2. The prepared bound products were scanned by electron microscope and sprayed on board respectively.

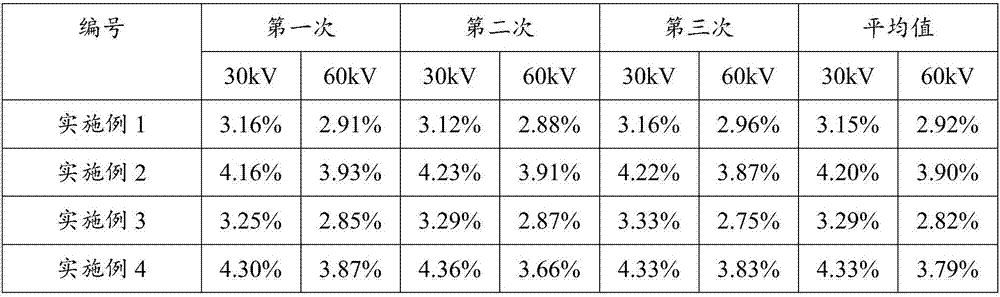

[0048] The metal powder is well bound to the powder coating particles; when the spraying voltage is 30kV and 90kV respectively, the measured metal powder content in the upper plate powder is 3.29% and 2.82%, which is different from the original addition of 3.00% metal powder The quantity is basically the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com