Formula and preparation method of animal marking paint

An animal marking and coating technology, applied in epoxy resin coatings, coatings and other directions, can solve the problems of pollution, reduction of wool grade, and reduction of economic benefits of farmers and herdsmen, and achieves good color retention, no irritating odor, good color retention The effect of gloss and color retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

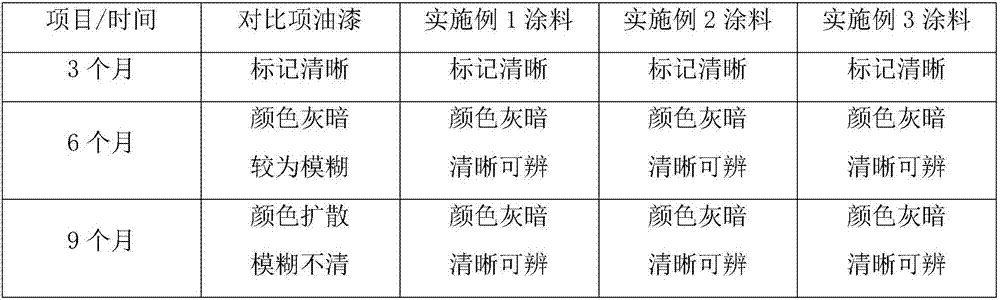

Examples

Embodiment 1

[0025] The invention provides a technical solution: a formula for animal marking paint, which consists of the following raw materials in weight percentage:

[0026] Acrylic resin: 12%;

[0027] Epoxy resin: 15%;

[0028] Organic solvent: 8%;

[0029] Organic bentonite: 2%;

[0030] Emulsifier: 0.6%;

[0031] Dispersant: 0.3%;

[0032] Colorant: 0.3%;

[0033] Water: 48%.

Embodiment 2

[0035] A kind of formula of animal marking paint, is made up of the raw material of following percentage by weight:

[0036] Acrylic resin: 18%;

[0037] Epoxy resin: 18%;

[0038] Organic solvent: 10%;

[0039] Organic bentonite: 2% to 8%;

[0040] Emulsifier: 0.8%;

[0041] Dispersant: 0.6%;

[0042] Colorant: 0.4%;

[0043] Water: 56%.

Embodiment 3

[0045] A kind of formula of animal marking paint, is made up of the raw material of following percentage by weight:

[0046] Acrylic resin: 24%;

[0047] Epoxy resin: 21%;

[0048] Organic solvent: 14%;

[0049] Organic bentonite: 8%;

[0050] Emulsifier: 1.2%;

[0051] Dispersant: 0.9%;

[0052] Colorant: 0.6%;

[0053] Water: 48% to 68%.

[0054] In above-mentioned embodiment 1 to embodiment 3, described organic solvent all adopts styrene; Described emulsifying agent adopts monoglyceride diacetyl tartrate; Described coloring agent adopts acrylic paint.

[0055] And in above-mentioned embodiment 1 to embodiment 3, the preparation method of this animal marking paint comprises the steps:

[0056] (1) Crushing and grinding of raw materials: according to the above formula, acrylic resin, epoxy resin and organic bentonite are respectively put into a sand mill and fully ground, and after being stirred evenly, they are bottled for use;

[0057] (2) Organic fusion: dissolve t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com