A preparation method of nanocellulose, nanocellulose and water purification membrane, and a preparation method of water purification membrane

A technology of nano-cellulose and α-cellulose, applied in chemical instruments and methods, permeation/dialysis water/sewage treatment, membranes, etc., can solve the problems of inability to meet the requirements of water purification membranes, low service life, and poor durability of natural fiber membranes , to achieve the effect of safe separation operation method, low density and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The embodiment of the present invention provides a kind of preparation method of nanocellulose, such as figure 1 shown, including the following steps:

[0057] Step 1: Raw material pretreatment: take the asparagus grass and cut it and crush the asparagus powder, put the asparagus powder into the fermentation tank for biodegradation to obtain the raw material for degradation treatment;

[0058] Step 2: Prepare α-cellulose; take the dehydrated raw materials for degradation treatment and add them to ionic liquids, stir and mix them for solid-liquid separation to obtain filtrate A and filter residue B, add filter residue B to ionic liquids, heat to dissolve, and undergo solid-liquid separation Obtain filtrate C and filter residue D, add ethanol to filtrate C and obtain alpha cellulose through solid-liquid separation;

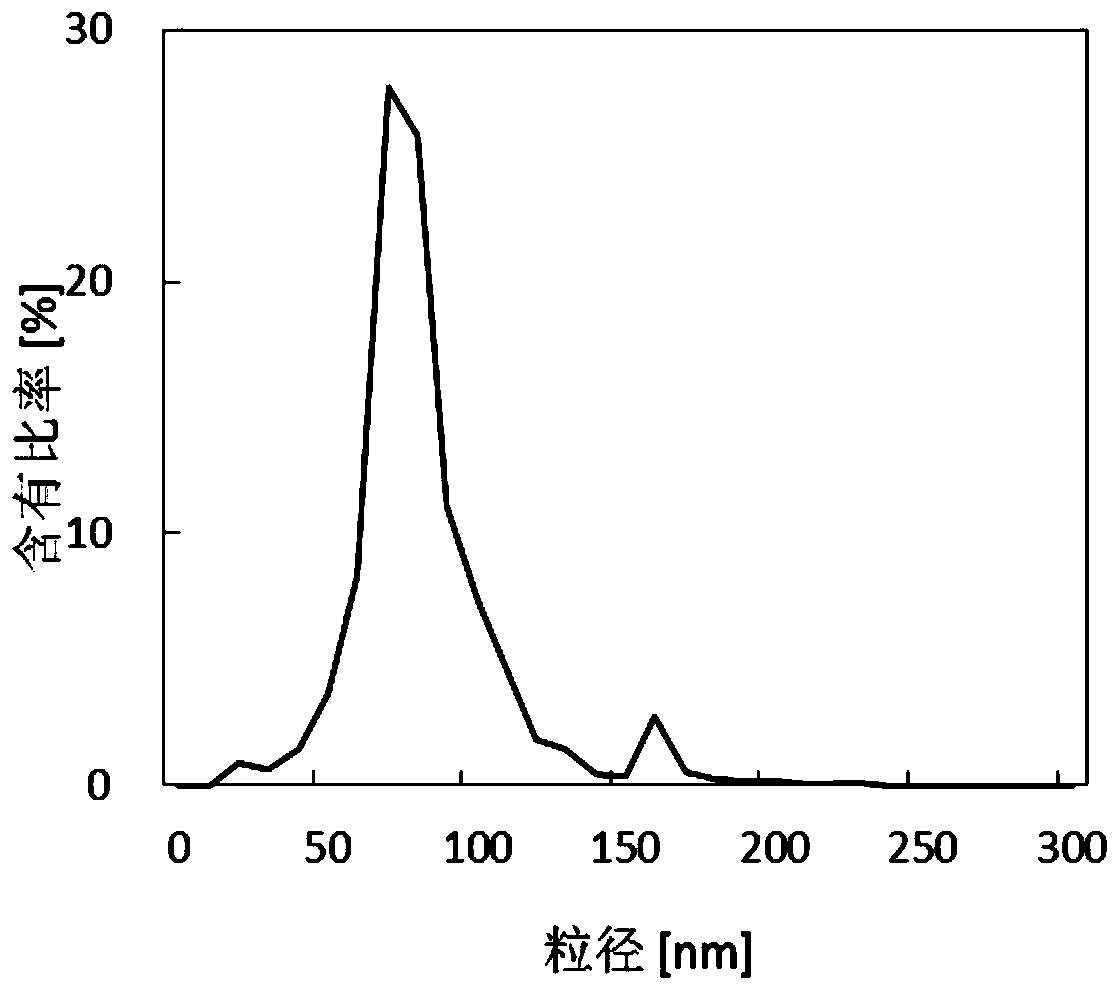

[0059] Step 3: Preparation of nanocellulose: take anhydrous phosphoric acid to prepare anhydrous phosphoric acid solution, mix the α cellulose prepared in s...

Embodiment 1

[0099] A preparation method of nanocellulose, comprising the following steps:

[0100] Step 1: Raw material pretreatment: take asparagus grass and cut and crush the asparagus powder, take the asparagus powder and put it into the fermentation tank, and add hemicellulase to make the hemicellulose concentration in the fermentation tank 0.05g / L, the temperature in the fermentation tank is 50°C, and the biodegradation time is 24 hours; biodegradation is carried out to obtain raw materials for degradation treatment;

[0101] Step 2: Prepare α-cellulose; take the dehydrated degraded raw material and add 2-methoxyethyl-1-methylpyrrolidinium lysine salt according to the solid-to-liquid ratio of 1:1, and the mixing condition is stirring at 50°C 2h, after stirring and mixing, carry out solid-liquid separation to obtain filtrate A and filter residue B, take filter residue B and add methoxyethyl bisethyl methylamine alanine salt, heat to dissolve, and obtain filtrate C and filter residue ...

Embodiment 2

[0105] A preparation method of nanocellulose, comprising the following steps:

[0106] Step 1: Raw material pretreatment: take asparagus grass and cut and crush the asparagus powder, take the asparagus powder and put it into the fermentation tank, and add hemicellulase, so that the hemicellulose concentration in the fermentation tank is 0.1g / L, the temperature in the fermentation tank is 45°C, and the biodegradation time is 26 hours; biodegradation is carried out to obtain the degradation treatment raw materials;

[0107] Step 2: Prepare α-cellulose; take the dehydrated degraded raw material and add 2-methoxyethyl-1-methylpyrrolidinium lysine salt according to the solid-to-liquid ratio of 1:1, and the mixing condition is stirring at 60°C 3h, after stirring and mixing, carry out solid-liquid separation to obtain filtrate A and filter residue B, take filter residue B and add methoxyethyl bisethyl methylamine alanine salt, heat to dissolve, obtain filtrate C and filter residue D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com