Pneumatic high-temperature superconducting magnetic levitation rail vehicle system

A high-temperature superconducting, rail car technology, applied in electric vehicles, vehicle components, railway vehicle testing, etc., can solve the problems of increasing train operating costs, expensive guide rail manufacturing costs, and reducing train effective load capacity, so as to improve the effective load capacity. , the structure is simple, the effect of reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings, so that those skilled in the art can better understand the present invention.

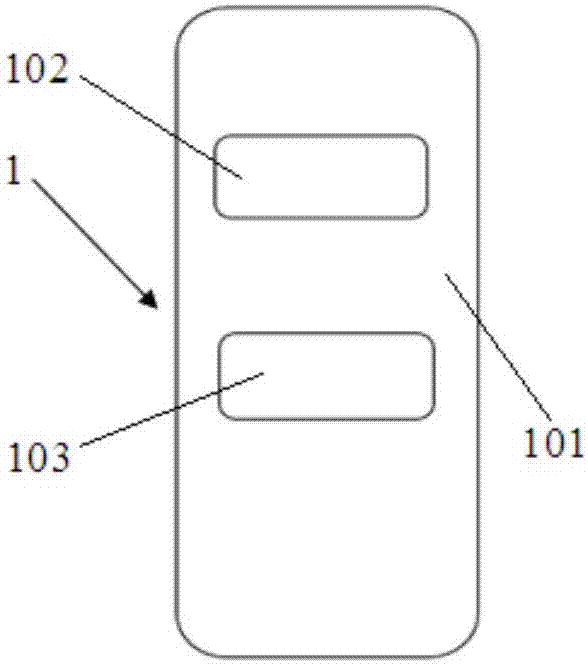

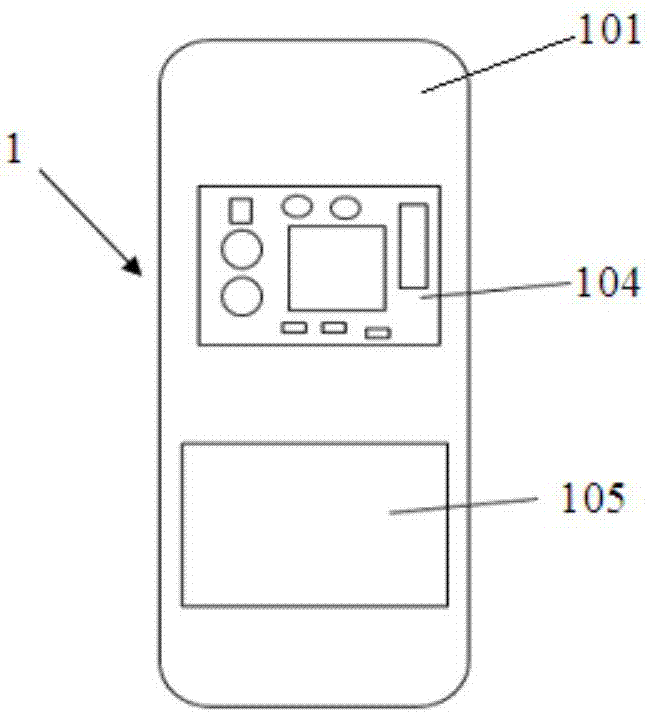

[0030] A pneumatic high-temperature superconducting maglev rail car system of the present invention includes a remote controller 1 , a permanent magnet rail 2 and a superconducting rail car 3 . Such as figure 1 with figure 2 As shown, the remote controller 1 includes a remote control box 101. The remote control box 101 is provided with a button one 102 and a button two 103. The button one 102 represents "forward", and the button two 103 represents "backward". There are remote control battery 104 and signal transmission system 105, remote control battery 104 adopts 9V battery, is used for powering signal transmission system 105, and signal transmission system 105 is used for issuing instructions.

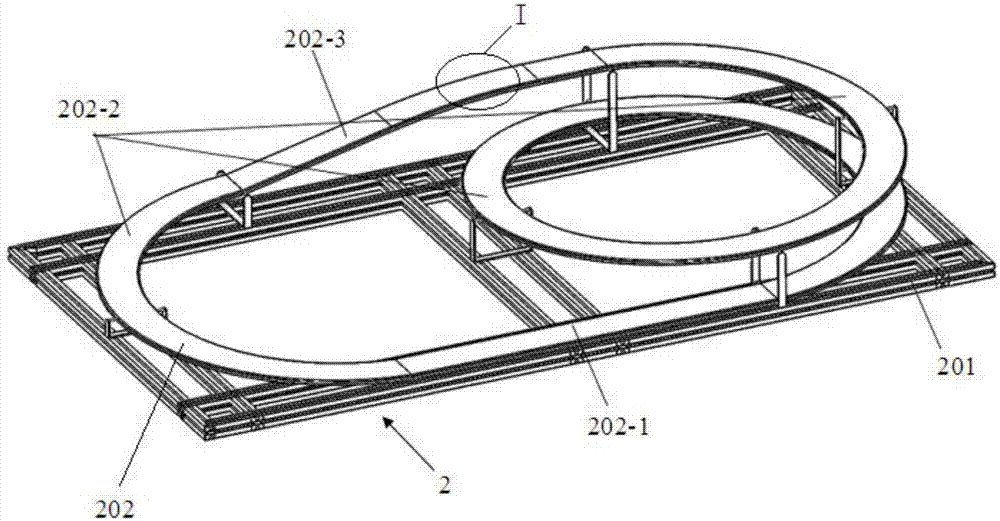

[0031] Such as image 3 with Figure 4 As shown, the permanent magnet track...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com