Modeling method for mass transfer rate structure-effect regulating model of micro-interface enhanced reactor

A model modeling and reactor technology, applied in the fields of instruments, special data processing applications, chemical process analysis/design, etc., can solve the problems of difficult universal application, high energy consumption and high manufacturing cost of microbubble equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0273] Method of the present invention specifically comprises the steps:

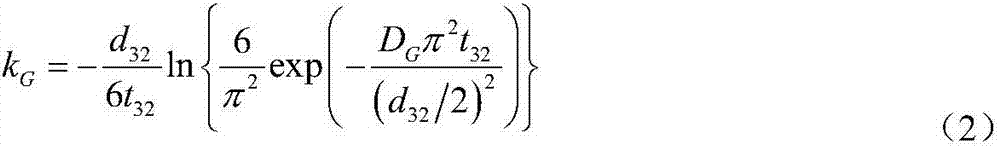

[0274] Step 10: Establish the gas side mass transfer coefficient k G Computational model;

[0275] According to membrane theory, the gas side mass transfer coefficient k G The size is determined by the gas phase diffusion coefficient D G and effective gas film thickness δ G Decide;

[0276] Based on the Chapman-Enskog motion theory, D G The general form of is:

[0277]

[0278] In the formula, T is the gas temperature; M A , M B Respectively, the molar mass of gas A and solvent B, Kg / mol; P G is the average pressure of the gas in the bubbles in the reactor, Pa;

[0279] For medium and high temperature gases, the accuracy of the above formula is relatively high, and the general error is within 5-10%. It can be seen from the formula that when the gas composition is constant, D G It increases with the increase of temperature and decreases with the increase of gas partial pressure. D of low d...

Embodiment 2

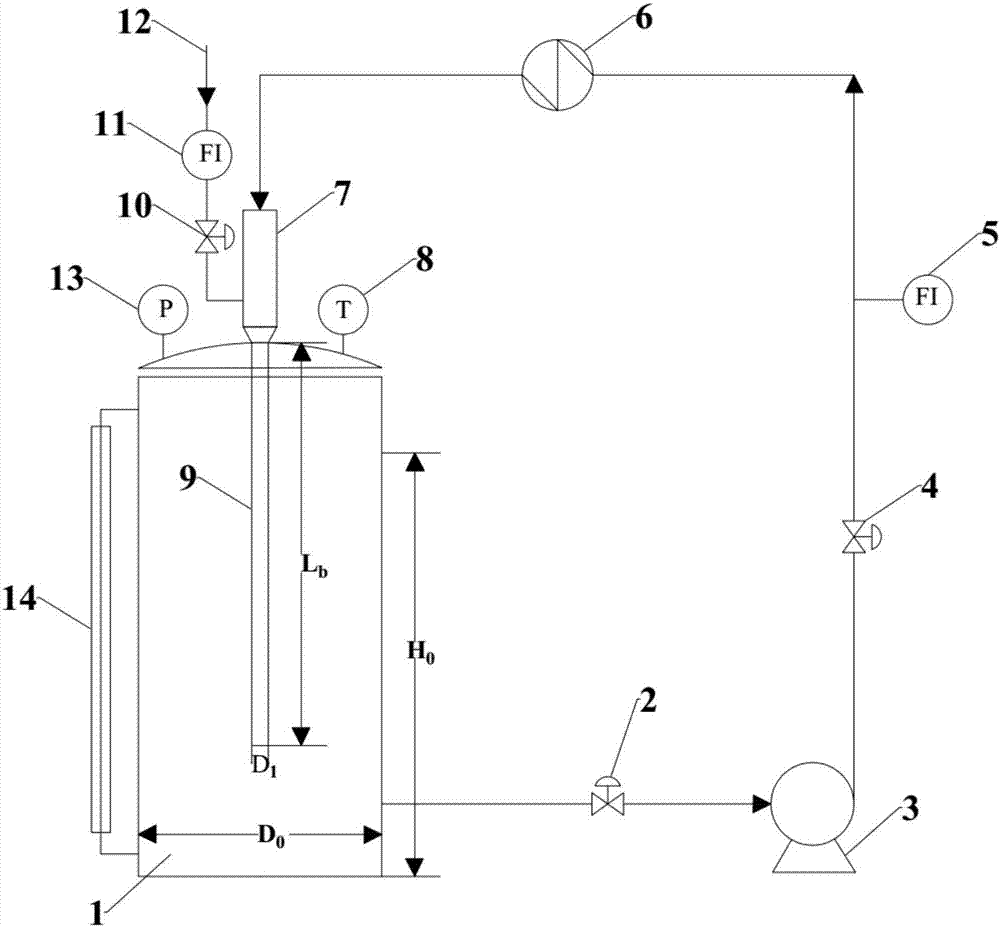

[0461] This embodiment takes figure 1 The reactor shown is taken as an example to illustrate the application of the model constructed by the modeling method described in Example 1 in the carbon dioxide and water system reactor. figure 1 The structure of the reactor can be the structure of the existing reactor, and only the method of the present invention is used for parameter design, and the structure of the reactor is not described in detail in the present invention.

[0462] The mass transfer rate structure-effect control model constructed according to Example 1 is as follows:

[0463]

[0464]

[0465]

[0466] d min =11.4(μ L / ρ L ) 0.75 ε -0.25 (33)

[0467] d max =0.75(σ L / ρ L ) 0.6 ε -0.4 (36)

[0468]

[0469]

[0470]

[0471]

[0472]

[0473]

[0474]

[0475]

[0476]

[0477] In the formula, d 32 is the average Sauter diameter of bubbles in the reactor, m; d min 、d max are the largest and smallest bubble diamet...

Embodiment 3

[0478] The model selected in embodiment 3 mainly considers L mix less than L b The situation, because the opposite situation is not common, more extreme. The structural parameters of the reactor also need to satisfy: λ 1 =0.1~0.5、K 1 =0.5,L b =13D 1 .

[0479] For carbon dioxide and water system, when the operating conditions are: Q L =2000L / h(5.56×10 -4 m 3 / s), gas flow Q G =0.2Q L , T=298K, P G0 =1atm; and the physical parameters of the liquid phase in this system are: ρ L =1000kg / m 3 , μ L =8.9×10 -4 Pa s, σ L =7.197×10 -4 N / m; diameter of reactor bubble breaker tube D 1 =0.02m; E 0 Indicates the energy input by the system, that is, the rated power on the nameplate of the circulating pump, take E 0 = 1000W. According to the operating conditions and the above model, the average diameter of bubble Sauter is calculated by applying MIR 32 The mass transfer rates of gas side and liquid side when =0.1mm are k G =1.78×10 -6 mol / Pa·m 3 s, k L =5.75×10 -4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com