Motor stator and shell installation structure designed with spray bars and design method for spray bar

A technology for mounting structures and motor stators, which is applied in the direction of electromechanical devices, manufacturing motor generators, casings/covers/supports, etc., can solve the problems that the installation structure of motor stators and casings cannot meet the needs of actual use, and achieve simple structure , easy to implement, and ensure the consistency of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to have a further understanding and understanding of the structural features of the present invention and the effects achieved, the preferred embodiments and drawings are used in conjunction with detailed descriptions, which are described as follows:

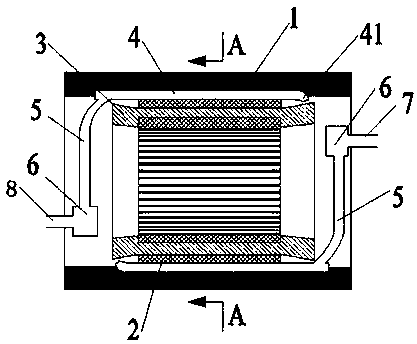

[0045] Such as figure 1 As shown, a motor stator and housing installation structure with a fuel injection pipe design according to the present invention includes a housing 1 and a stator core 2. The stator core 2 is installed in the housing 1, and the stator core 2 It is still installed with the housing 1 using the traditional thermal sleeve process, but there is no need to consider the issue of interference fit.

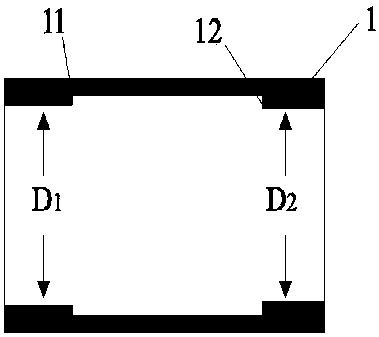

[0046] Such as image 3 As shown, the two ends of the inner surface of the housing 1 are respectively provided with a ring-shaped boss A11 and a ring-shaped boss B12, the ring-shaped boss A11 and the ring-shaped boss B12 are used to limit the stator core 2 Therefore, the inner diameter of the housing 1 at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com