Flexible substrate structure and preparation method thereof

A technology for flexible substrates and rigid substrates, which is applied in the preparation of flexible display devices, flexible substrate structures and their preparation fields, can solve the problems of flexible materials falling off and cannot be removed from the mold, and achieves the effect of ideal adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

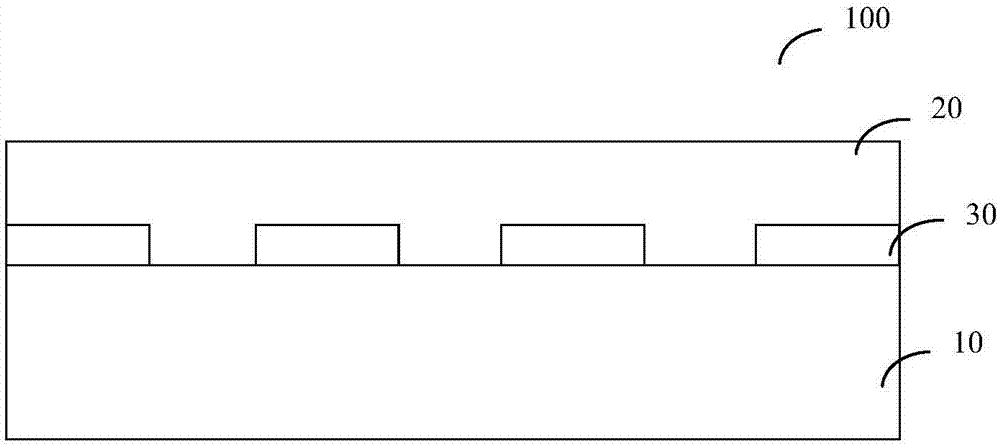

[0050] Such as figure 1 As shown, this embodiment discloses a flexible substrate structure 100, including a rigid substrate 10 and a flexible substrate 20 disposed on the rigid substrate 10, and may also include:

[0051] A plurality of island structures 30 are discretely distributed on the upper surface of the rigid substrate 10, and the flexible substrate 20 covers the upper surface and side walls of the plurality of island structures 30 and the exposed upper surface of the rigid substrate 10;

[0052] The adhesive force per unit area between the flexible substrate 20 and the rigid substrate 10 is different from the adhesive force per unit area between the flexible substrate 20 and the island structure 30 .

[0053] In the above technical solution, since there are discretely distributed island structures 30 between the rigid substrate 10 and the flexible substrate 20, and the adhesive force per unit area between the flexible substrate 20 and the rigid substrate 10 is differe...

Embodiment 2

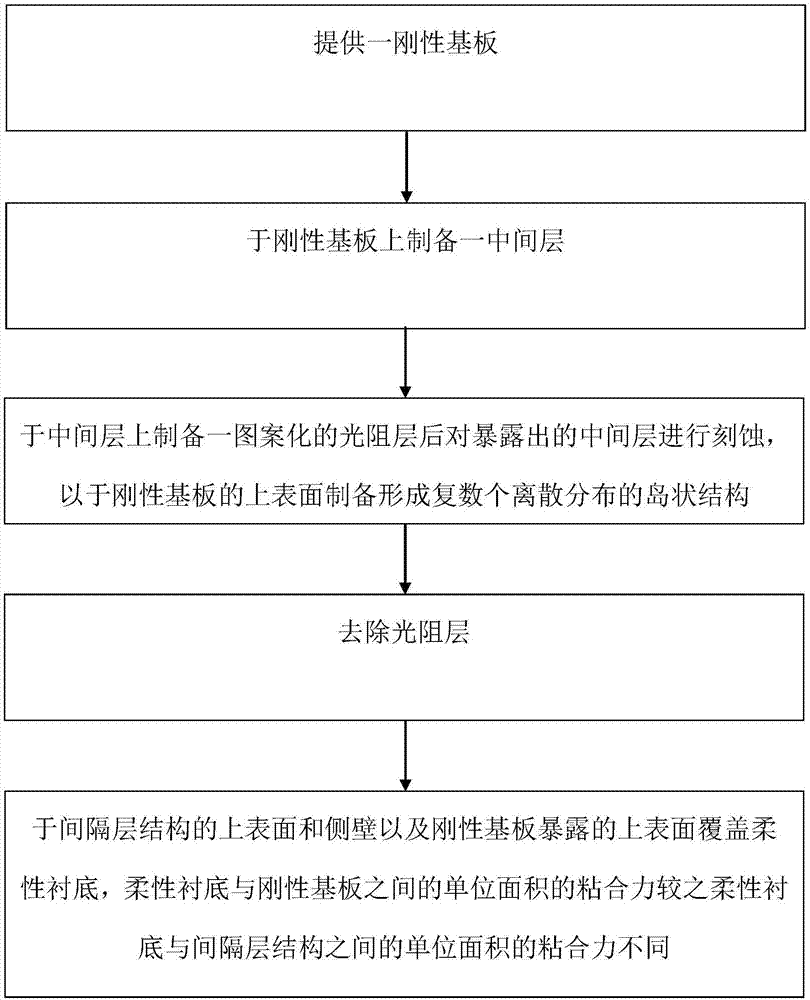

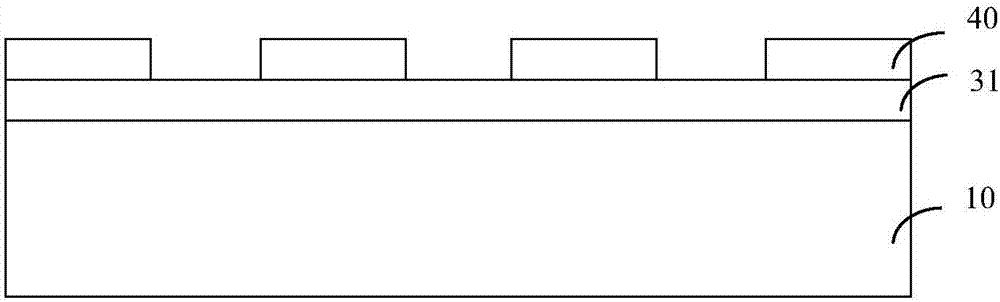

[0057] Such as figure 2 As shown, it also includes a method for preparing a flexible substrate structure, and the structure formed in each preparation step can be as follows Figure 3-5 As shown in the structure, the preparation method may include:

[0058] providing a rigid substrate 10;

[0059] Prepare an intermediate layer 31 on the rigid substrate 10;

[0060] After preparing a patterned photoresist layer 40 on the intermediate layer 31, the exposed intermediate layer 31 is etched, so as to form a pattern on the upper surface of the rigid substrate 10 such as Figure 4 The plurality of discretely distributed island structures 30 shown;

[0061] removing the photoresist layer 40;

[0062] A flexible substrate 20 is covered on the upper surface and side walls of the island structure 30 and the exposed upper surface of the rigid substrate 10 to form Figure 5 structure shown. Wherein, the adhesive force per unit area between the flexible substrate 20 and the rigid sub...

Embodiment 3

[0070] Such as Figure 6 Shown, also includes a kind of preparation method of flexible display device, this preparation method may comprise:

[0071] providing a rigid substrate 10;

[0072] Prepare an intermediate layer 31 on the rigid substrate 10;

[0073] Prepare a patterned photoresist layer 40 on the intermediate layer 31 and then etch the exposed intermediate layer 31 to prepare and form a plurality of discretely distributed island structures 30 on the upper surface of the rigid substrate 10;

[0074] removing the photoresist layer 40;

[0075] Covering a flexible substrate 20 on the upper surface and side walls of the island structure 30 and the exposed upper surface of the rigid substrate to obtain a flexible substrate structure 100;

[0076] Executing a predetermined process combination on the flexible substrate structure 100 to form a composite structure having a thin film transistor device structure and an organic light emitting diode device structure;

[0077]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com