Deep load testing device

A load test and deep layer technology, which is applied in the field of foundation soil survey, construction, infrastructure engineering, etc., can solve the problems of hole wall collapse, low monitoring accuracy of bearing plate sinking, hole wall necking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

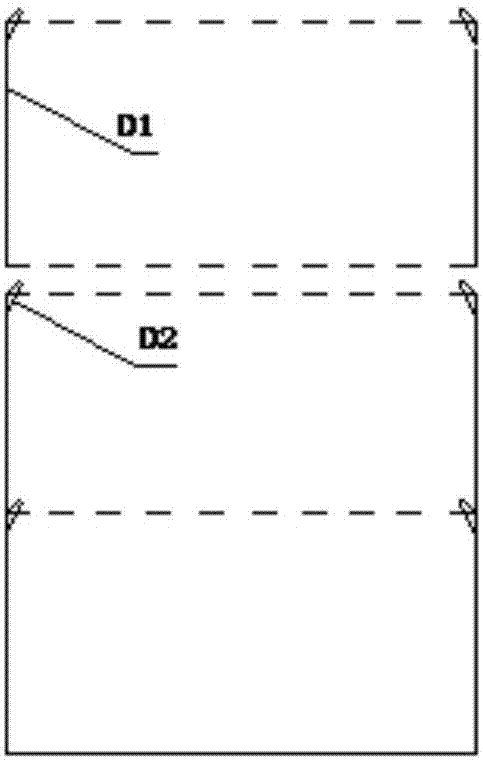

[0021] Such as figure 1 Shown: including the pressure plate A set at the bottom of the foundation pit, above the pressure plate A there is a transmission column B and a displacement rod C, the displacement rod C is located on both sides of the transmission column B, and the top of the displacement rod C is set There is a displacement rod fixing plate E, and an automatic numerical control pressure device F is installed on the top of the transmission column B; an arm sleeve D is arranged along the inside of the foundation pit.

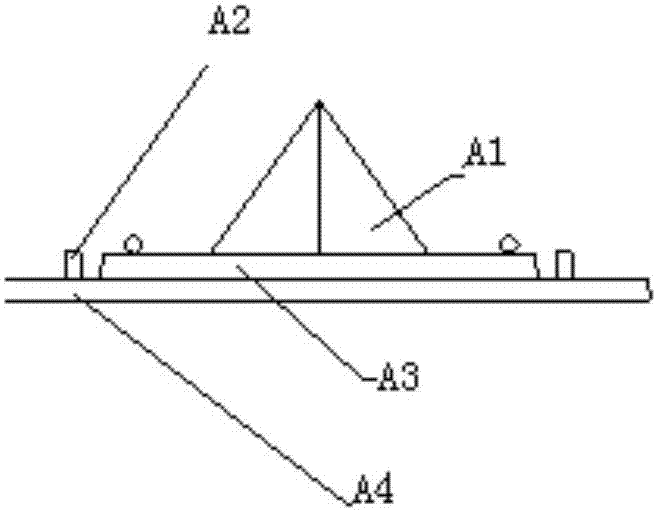

[0022] Such as figure 2 As shown: the four directions of the pressure plate A are equipped with moving rod connecting screw ports A2, and the pressure plate A is placed downward through the four displacement rods C, which can ensure that the pressure plate A is installed horizontally. As for the test surface, the pressure plate A The level o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com