Method for preparing high-silicon steel sheet by gas dynamic spraying

A gas dynamic spraying, high silicon steel technology, applied in pressure inorganic powder coating and other directions, can solve the problems of complex equipment structure, low deposition rate, high preparation cost, and achieve the effects of increased deposition rate, simple equipment, and fast film formation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

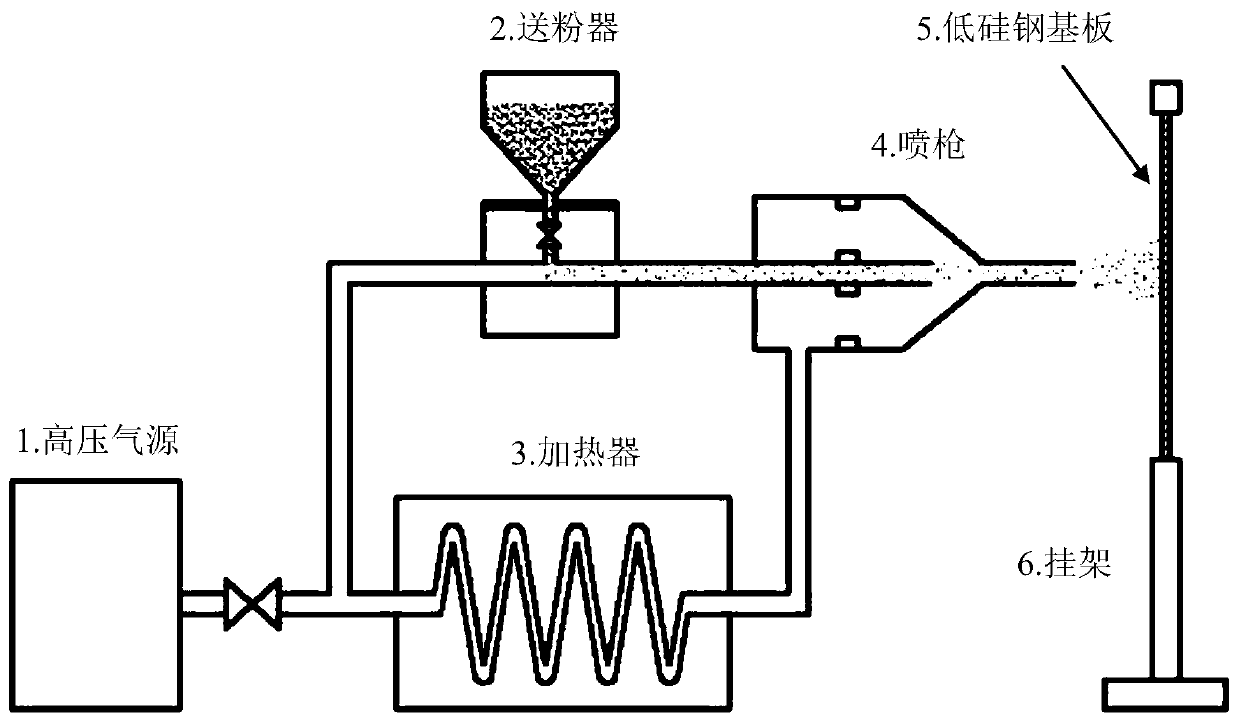

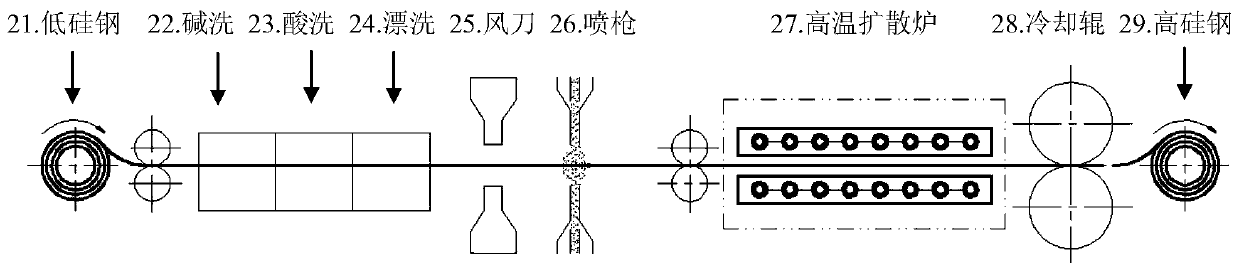

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1: A method for preparing Fe-5.5~6.5wt.%Si high-silicon steel sheet by gas dynamic spraying, the steps of preparation by single-sided spraying are:

[0057] Step 1. Select a low-silicon steel sheet with a thickness of 0.15mm and a Si content of 2wt.% as the substrate, and perform the following pretreatment:

[0058] (1) Wash with sodium hydroxide solution with a concentration of 10% and a temperature of 80° C. for 5 minutes to remove oil stains on the surface of the substrate;

[0059] (2) Wash with 4% dilute hydrochloric acid for 5 minutes to remove rust and scale on the surface of the substrate;

[0060] (3) rinse with water;

[0061] (4) Ultrasonic cleaning with anhydrous ethanol, drying for later use;

[0062] Step 2. Spray powder preparation

[0063] (1) mix metal silicon with purity ≥ 99.9% and high-purity iron with purity ≥ 99.9% in a weight ratio of 40:60, wherein the metal silicon is 40;

[0064] (2) Place the ingredients in a vacuum induction me...

Embodiment 2

[0074] Embodiment 2: A method for preparing Fe-5.5~6.5wt.%Si high-silicon steel sheet by gas dynamic spraying, the steps of double-sided spraying preparation are:

[0075] Step 1. Select a low-silicon steel sheet with a thickness of 0.35mm and a Si content of 3wt.% as the substrate, and perform the following pretreatment:

[0076] (1) Wash with sodium hydroxide solution with a concentration of 12% and a temperature of 60° C. for 5 minutes to remove oil stains on the surface of the substrate;

[0077] (2) Wash with 4% dilute hydrochloric acid for 3 minutes to remove rust and scale on the surface of the substrate;

[0078] (3) rinse with water;

[0079] (4) Ultrasonic cleaning with anhydrous ethanol, drying for later use;

[0080] Step 2. Spray powder preparation

[0081] (1) Mix metal silicon with a purity of ≥99.9% and high-purity iron with a purity of ≥99.9% in a weight ratio of 25:75, wherein the metal silicon is 25;

[0082] (2) Place the ingredients in a vacuum inducti...

Embodiment 3

[0092] Example 3 Preparation of Fe-6.5wt.% Si high-silicon steel by spraying high-Si coating on one side of low-silicon steel substrate

[0093] Step 1: Select low-silicon steel substrate

[0094] Select a 200mm×200mm, 0.35mm thick, low-silicon steel sheet with a Si content of 3wt.% as the substrate, first wash it with a sodium hydroxide solution with a concentration of 10% and a temperature of 80°C for 5 minutes to remove oil stains; then use dilute hydrochloric acid with a concentration of 4% Wash for 5 minutes to remove rust and oxide skin, etc.; then rinse with water, ultrasonically clean with absolute ethanol, and dry for later use;

[0095] Step 2. Spray powder preparation

[0096] (1) 2000 grams of metal silicon with a purity of ≥99.9% and high-purity iron with a purity of ≥99.9% are prepared in a weight ratio of 33:67;

[0097] (2) Place the ingredients in a vacuum induction melting furnace, and vacuumize to make the background vacuum in the furnace reach 10 -4 Pa l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com