Streptococcus equi subsp. Zooepidemicus subspecies SXY36 and application in fermentation production of hyaluronic acid

A technology of Streptococcus equi and hyaluronic acid, which is applied in the direction of fermentation, microbial-based methods, bacteria, etc., can solve the problems of limited application, fermentation cost and HA production, and achieve high fermentation yield and genetic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: mutagenesis of Streptococcus equi subspecies zooepidemicus SXY36 strain

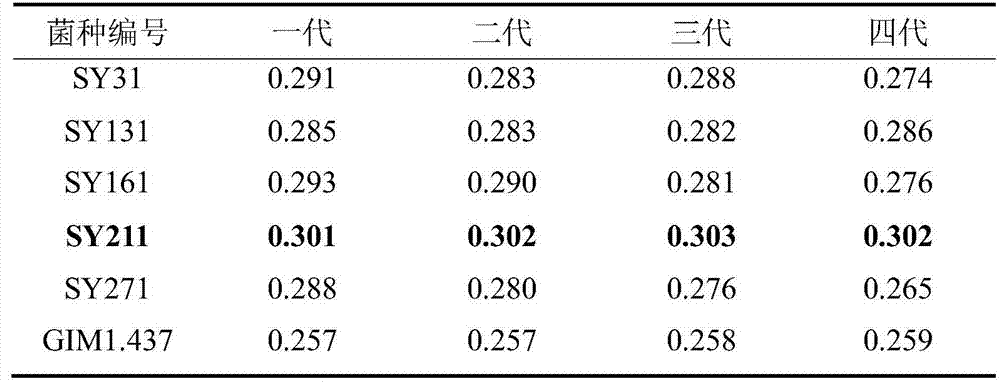

[0026] The HA fermentation yield of Streptococcus equi subsp. It carries out continuous mutagenesis, and selects high-yielding strains from the mutants.

[0027] (1) UV mutagenesis

[0028] Prepare the bacterial suspension of the starting strain GIM1.437, after mutagenesis by ultraviolet radiation, the bacterial liquid is diluted and spread on a plate medium for culture, pick a single colony and transfer it to the slant medium to obtain the strain, and then insert the bacteria of each strain Shake flask culture medium was cultivated at 37°C and 200r / min for 24 hours, and the HA content was detected. The strains with HA production rate increased by more than 10% were screened out initially, and then subcultured and re-screened to obtain mutant strains with significantly increased HA fermentation production rate.

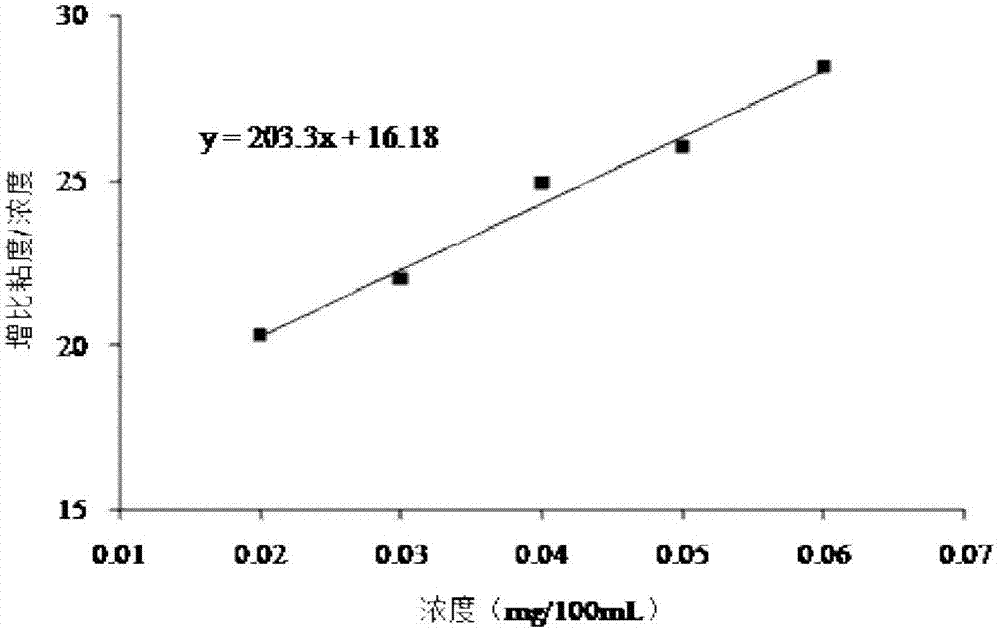

[0029] The ultraviolet mutagenesis method is as follows: turn on the ...

Embodiment 2

[0062] Embodiment 2: the method for producing HA by SXY36 strain shake flask fermentation under optimal conditions

[0063] Using the SXY36 strain as the strain, after optimizing the composition of the fermentation medium and the fermentation conditions, the yield of HA produced by shake flask fermentation was significantly improved. The specific steps are as follows:

[0064] (1) The SXY36 strain stored in frozen glycerol tubes was inoculated on the slant medium, and cultured at 37° C. for 24 hours to obtain the activated slant of the SXY36 strain. The final concentration of the slant medium consists of: glucose 2g / L, beef extract 5g / L, peptone 5g / L, yeast extract powder 2g / L, K 2 HPO 4 2.5g / L, MgSO 4 1.5g / L, agar 20g / L, solvent is distilled water, pH is 7.0.

[0065] (2) Inoculation loop picking step (1) After activation culture, 2 loops of SXY36 bacteria were inoculated into 100mL seed medium, cultured at 37°C and 200r / min shaking for 24 hours, and the concentration of d...

Embodiment 3

[0067] Embodiment 3: the method that SXY36 strain produces hyaluronic acid in fermentor

[0068] Using the SXY36 strain as the strain, use a 10L mechanically stirred fermenter to ferment and produce hyaluronic acid. The specific steps are as follows:

[0069] (1) SXY36 cells stored in frozen glycerol tubes were inoculated on the slant medium, and cultured at 37° C. for 24 hours to obtain the activated slant of the SXY36 strain. Described slant culture medium composition and preparation method are with embodiment 2;

[0070] (2) Inoculation loop picking step (1) After activation culture, 2 loops of SXY36 cells were inoculated into 3 bottles of 100mL seed medium, cultured at 37°C and 200r / min shaking for 24h, and the concentration of dry cells was 1.37 g / L seed liquid; described seed medium composition and preparation method are with embodiment 2;

[0071] (3) Transplant the seed solution of step (2) into 6L fermentation medium with an inoculum volume concentration of 2%, that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com