Method for preparing sodium glutamate by using glutamic acid fermentation broth.

A technology of sodium glutamate and ammonia glutamate, applied in fermentation, cyanide reaction preparation, chemical instruments and methods, etc., can solve the problems of discharge, acid-base consumption, large waste liquid, etc. The effect of less and high sterilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

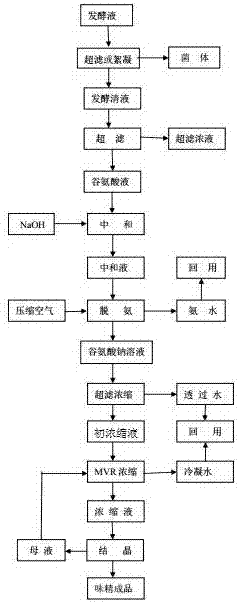

[0034] Take the glutamic acid fermentation broth and use a high-speed centrifuge. Firstly, the bacterial cells in the glutamic acid fermentation liquid are separated to obtain a liquid containing ammonium glutamate. Bacteria are used to produce feed. Pass the above-mentioned fermented liquid with ammonium glutamate removed from bacteria through an ultrafiltration membrane to intercept residual sugar, pigment, protein, colloidal substances and other fermentation by-products, etc., to obtain an ammonium glutamate solution. The ultrafiltration retentate is combined with the aforementioned bacteria to produce feed. The obtained ammonium glutamate solution is neutralized with NaOH, the pH is controlled at 6-8, and the temperature is 60-80° C. to obtain the aqueous solution of sodium glutamate and ammonia. When the temperature is 60-80°C, use compressed air to remove the ammonia generated in the neutralizing solution, and then concentrate it to the initial concentrated solution wi...

Embodiment 2

[0038] The glutamic acid fermentation broth is taken, and the bacteria, residual sugar, pigment, protein, colloidal substances and other fermentation by-products in the glutamic acid fermentation broth are separated by an ultrafiltration membrane to obtain a liquid containing ammonium glutamate. The ultrafiltration retentate is used to produce feed. The above-mentioned fermented liquid of ammonium glutamate from which bacteria cells have been removed is passed through an ultrafiltration membrane to obtain an ammonium glutamate solution. The ultrafiltration retentate is combined with the aforementioned bacteria to produce feed. The obtained ammonium glutamate solution is neutralized with NaOH, the pH is controlled at 6-8, and the temperature is 60-80° C. to obtain the aqueous solution of sodium glutamate and ammonia. When the temperature is 60-80°C, use compressed air to remove the ammonia generated in the neutralizing solution, and then concentrate it to the initial concentra...

Embodiment 3

[0042]Take the glutamic acid fermentation broth, add flocculant to the glutamic acid fermentation broth to coagulate and flocculate the bacteria and impurities in the fermentation broth, and then use the conventional air flotation method to separate the solid from the liquid. The liquid containing ammonium glutamate obtained by separating bacteria, residual sugar, pigment, protein, colloidal substances and other fermentation by-products. The flocs obtained by air flotation are used to produce feed. The above-mentioned fermented liquid of ammonium glutamate from which impurities have been removed is refined through an ultrafiltration membrane to obtain an ammonium glutamate solution. The ultrafiltration retentate is combined with the aforementioned flocs to produce feed. The obtained ammonium glutamate solution is neutralized with NaOH, the pH is controlled at 6-8, and the temperature is 60-80° C. to obtain the aqueous solution of sodium glutamate and ammonia. When the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com