Chromatographically pure tert-butyl methyl ether as well as preparation method and production system thereof

A technology of pure tert-butyl methyl ether and tert-butyl methyl ether, which is applied in the field of chemical product purification, can solve the problems of not meeting scientific research requirements, low product purity and low yield, etc., and achieves the effects of efficient preparation, simple process and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

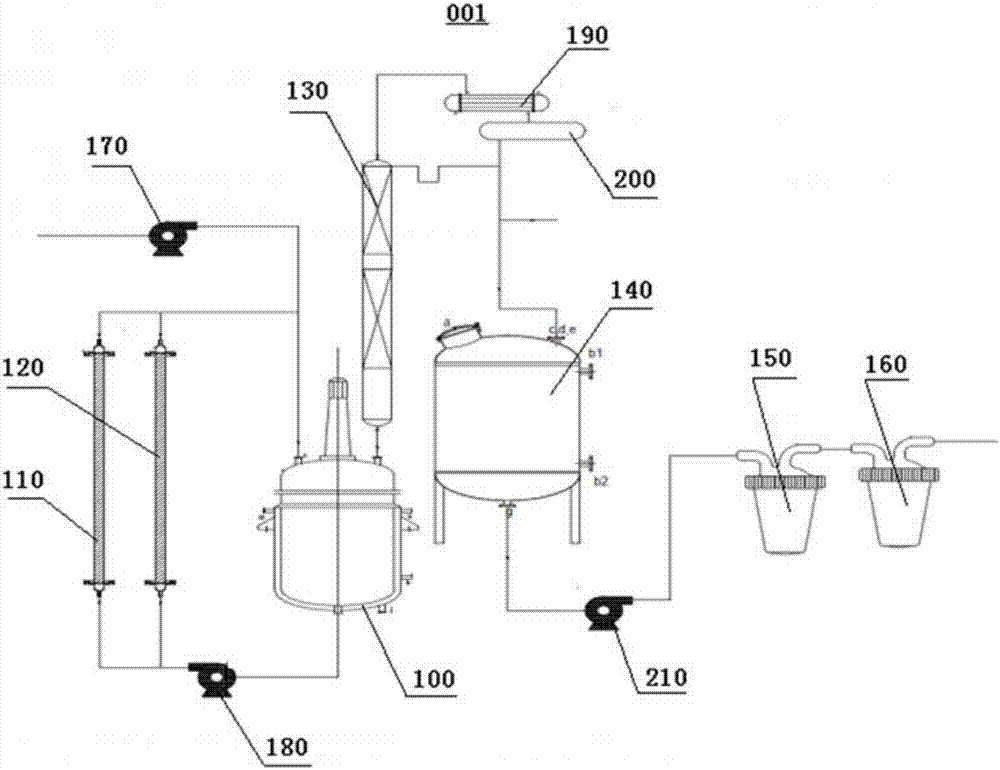

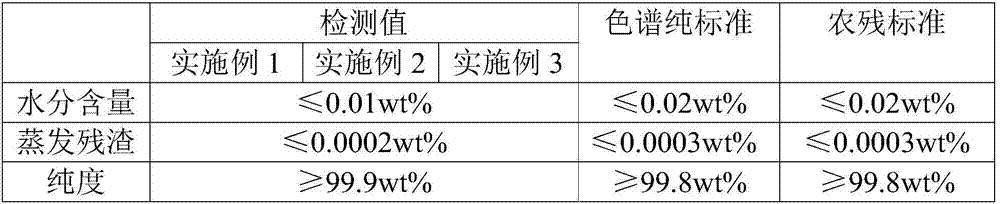

[0048] The present embodiment provides a kind of chromatographically pure tert-butyl methyl ether, which adopts figure 1 Shown production system 001, and make according to following preparation method:

[0049] S101, 4A molecular sieve adsorption: use industrial-grade tert-butyl methyl ether as a raw material, transport it to the reaction kettle 100 through the raw material delivery pump 170, close the raw material delivery pump 170, and cut off the reaction kettle 100 and the alumina adsorption column through a valve (not shown in the figure) 120, and connect the pipeline between the reaction kettle 100 and the 4A molecular sieve post 110, and open the circulation pump 180 to establish the bottom of the reaction kettle 100, the circulation pump 180, the 4A molecular sieve post 110 and the reaction kettle 100 The circulating pipeline at the top is used for circulating adsorption. The circulating pump 180 controls the flow rate of tert-butyl methyl ether in the 4A molecular sie...

Embodiment 2

[0054] The present embodiment provides a kind of chromatographically pure tert-butyl methyl ether, which adopts figure 1 Shown production system 001, and make according to following preparation method:

[0055] S201, 4A molecular sieve adsorption: use industrial-grade tert-butyl methyl ether as a raw material, transport it to the reaction kettle 100 through the raw material delivery pump 170, close the raw material delivery pump 170, and cut off the reaction kettle 100 and the alumina adsorption column through a valve (not shown in the figure) 120, and connect the pipeline between the reaction kettle 100 and the 4A molecular sieve post 110, and open the circulation pump 180 to establish the bottom of the reaction kettle 100, the circulation pump 180, the 4A molecular sieve post 110 and the reaction kettle 100 The circulating pipeline at the top is used for circulating adsorption. The circulating pump 180 controls the flow rate of tert-butyl methyl ether in the 4A molecular sie...

Embodiment 3

[0060] The present embodiment provides a kind of chromatographically pure tert-butyl methyl ether, which adopts figure 1 Shown production system 001, and make according to following preparation method:

[0061] S301, 4A molecular sieve adsorption: use industrial-grade tert-butyl methyl ether as a raw material, transport it to the reaction kettle 100 through the raw material delivery pump 170, close the raw material delivery pump 170, and cut off the reaction kettle 100 and the alumina adsorption column through a valve (not shown in the figure) 120, and connect the pipeline between the reaction kettle 100 and the 4A molecular sieve post 110, and open the circulation pump 180 to establish the bottom of the reaction kettle 100, the circulation pump 180, the 4A molecular sieve post 110 and the reaction kettle 100 The circulating pipeline at the top is used for circulating adsorption. The circulating pump 180 controls the flow rate of tert-butyl methyl ether in the 4A molecular sie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com