High-strength anti-crack concrete and preparation method thereof

A concrete and high-strength technology, applied in the field of concrete and its preparation, can solve the problems of low compressive strength and easy cracking, and achieve the effects of enhancing compressive strength and cracking strength, improving expansion effect, and slowing expansion speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

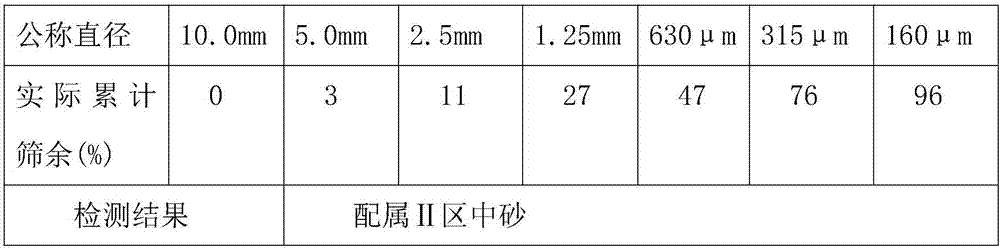

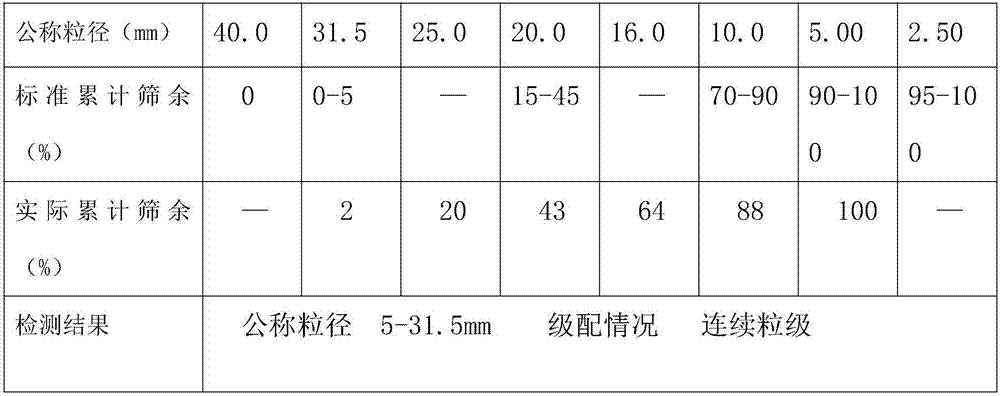

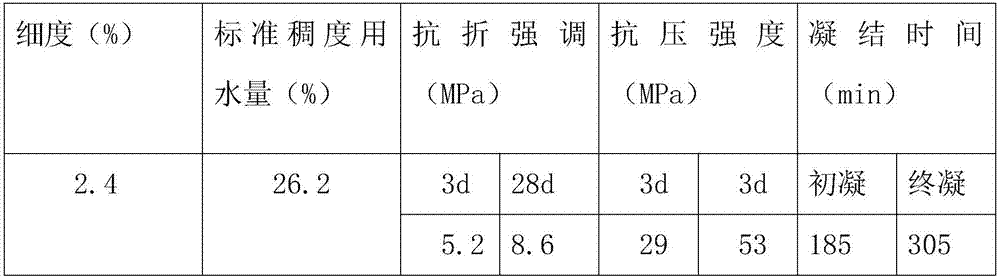

[0038] At 20-30°C, crush the stones to 950kg / m 3 , cement 250kg / m 3 , sand 650kg / m 3 , water 155kg / m 3 , Admixture 10-16kg / m 3 , Concrete expansion agent 10kg / m 3 and fly ash 75kg / m 3 Mix and stir for 10-20 minutes to make concrete product A1, wherein the mud content of the stone is ≤5%, the mud content of the sand is ≤3%, and the admixture is composed of the following raw materials in parts by weight : 50-65 parts of polycarboxylate water reducing agent, 2-8 parts of silicon carbide, 2-5 parts of hollow glass microspheres, 8-15 parts of silicon dioxide coated titanium dioxide and 1-5 parts of gelatin powder; The concrete expansion agent is composed of the following raw materials in parts by weight: 16-24 parts of calcium aluminosilicate, 22-35 parts of calcium sulfoaluminate, 5-9 parts of iron sulfate, 15-22 parts of sulfur-fixing waste residue, and 8-15 parts of red mud , 8-15 parts of modified calcium oxide, 4-6 parts of magnesium oxide, 5-9 parts of acrylic acid emul...

Embodiment 2

[0040] At 20-30°C, crush the stones at 1030kg / m 3 , Cement 350kg / m 3 , sand 680kg / m 3 , water 185kg / m 3 , Admixture 10-16kgkg / m 3 , Concrete expansion agent 14kg / m 3 and fly ash 65kg / m 3 Mix and stir for 10-20 minutes to make concrete product A2, wherein the mud content of the stone is ≤5%, the mud content of the sand is ≤3%, and the admixture is composed of the following raw materials in parts by weight : 50-65 parts of polycarboxylate water reducing agent, 2-8 parts of silicon carbide, 2-5 parts of hollow glass microspheres, 8-15 parts of silicon dioxide coated titanium dioxide, 1-5 parts of gelatin powder; The concrete expansion agent is composed of the following raw materials in parts by weight: 16-24 parts of calcium aluminosilicate, 22-35 parts of calcium sulfoaluminate, 5-9 parts of iron sulfate, 15-22 parts of sulfur-fixing waste residue, and 8-15 parts of red mud , 8-15 parts of modified calcium oxide, 4-6 parts of magnesium oxide, 5-9 parts of acrylic emulsion ...

Embodiment 3

[0042] At 20-30°C, the stone is 1000kg / m 3 , the cement is 265kg / m 3 , the sand is 650kg / m 3 , water is 174kg / m 3 , the admixture is 10.21kg / m 3 , the concrete expansion agent is 12.56kg / m 3, fly ash is 74.30kg / m 3 Mix and stir for 10-20 minutes to make concrete product A3, wherein the mud content of the stone is ≤5%, the mud content of the sand is ≤3%, and the admixture is composed of the following raw materials in parts by weight : 50-65 parts of polycarboxylate water reducer, 2-8 parts of silicon carbide, 2-5 parts of hollow glass microspheres, 8-15 parts of titanium dioxide coated with silicon dioxide, 1-5 parts of gelatin powder; The concrete expansion agent is composed of the following raw materials in parts by weight: 16-24 parts of calcium aluminosilicate, 22-35 parts of calcium sulfoaluminate, 5-9 parts of iron sulfate, 15-22 parts of sulfur-fixing waste residue, and 8-15 parts of red mud , 8-15 parts of modified calcium oxide, 4-6 parts of magnesium oxide, 5-9 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com