Integrated skid-mounted continuous mixing device and technology for acid liquor

An integrated acid solution technology, applied in mixers, mining fluids, fluid mixers, etc., can solve the problems of excess acid solution, poor mixing effect, environmental pollution, etc., and achieve fast mixing speed and high acid quality , the effect of mixing evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

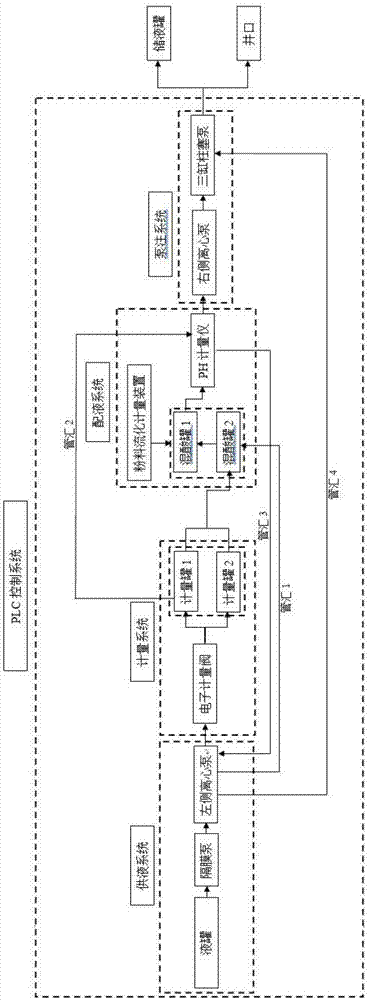

Image

Examples

specific Embodiment approach

[0028] According to the above-mentioned device, the specific implementation of the integrated skid-mounted acid solution continuous mixing process method of the present invention is as follows:

[0029]Continuous acid injection operation process: According to the requirements of the acid liquid ratio in the construction operation plan, by adjusting the speed knob of the centrifugal pump motor on the left side of the PLC control system, the flow rate of the suction liquid is controlled, and the pump is pumped from the liquid tank to the metering tank through the electronic metering valve. A fixed proportion of water and acid is injected, and the liquid flow rate is displayed by the electronic metering valve in the metering system, and the electronic metering valve feeds back real-time data to the PLC control system; water and acid enter the metering tank and are mixed, and the The manifold directly enters the pH meter, and the pH meter feeds back the pH value to the PLC control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com