An automatic weeding device based on the joint operation of drones

A joint operation and unmanned aerial vehicle technology, applied in the field of weeding machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

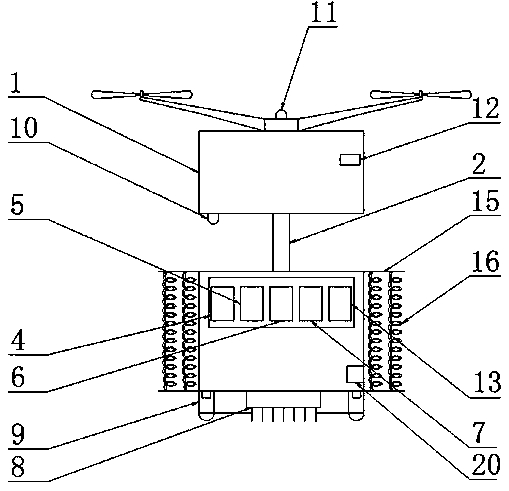

[0033] like figure 1 As shown, an automatic weeding device based on the joint operation of drones includes a drone 1, a connecting device 2 and a weeding mechanism 3, and the connecting device 2 is used to connect the drone 1 and the weeding mechanism 3 , the weeding mechanism 3 includes a processor 4, a driving device 5, a first navigation device 6, an expelling device 7, a roller blade 8 and a wheel 9, the driving device 5 is connected with the processor 4, and the first navigation device The device 6 is connected with the processor 4 for setting the walking route of the weeding mechanism 3, and the expelling device 7 is connected with the driving device 5 for expelling living things close to the weeding mechanism 3, so The drum blade 8 is connected with the driving device 5 through a transmission mechanism for cutting weeds, and the wheel 9 is connected with the driving device 5 for driving the weeding mechanism 3 to walk. The drone 1 includes The first camera 10, the seco...

Embodiment 2

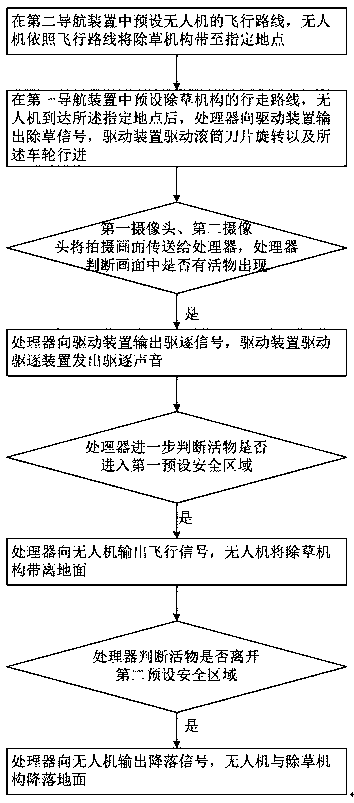

[0042] like image 3 As shown, a working method of an automatic weeding device based on unmanned aerial vehicle joint operation includes the following working steps: a) preset the flight route of the unmanned aerial vehicle 1 in the second navigation device 12, the unmanned aerial vehicle The man-machine 1 brings the weeding mechanism 3 to a designated place according to the flight route;

[0043] b) preset the walking route of the weeding mechanism 3 in the first navigation device 6, after the UAV 1 arrives at the designated location, the processor 4 outputs a weeding signal to the driving device 5, The driving device 5 drives the drum blade 8 to rotate and the wheel 9 to travel;

[0044] c) The first camera 10 and the second camera 11 transmit the shooting picture to the processor 4, and the processor 4 judges whether there is a living thing in the picture;

[0045] d) if so, output an expulsion signal to the driving device 5, and the driving device 5 drives the expulsion ...

Embodiment 3

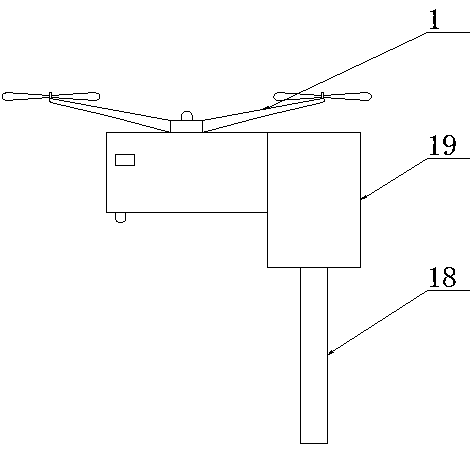

[0054] like Image 6 As shown, if the storage bin 19 is full, the processor 4 will mark the position of the garbage bin closest to the current position in the second navigation device 12, and the processor 4 will send the UAV 1 An unloading signal is output, and the UAV 1 carries the storage box 19 to the position for unloading.

[0055] Specifically, this embodiment provides two methods to judge whether the storage box 19 is full. One, a laser rangefinder is set at the top of the storage box 19, and the laser rangefinder is connected with the processor 4 for measuring the distance value of the grass clippings to the top of the storage box 19 and calculating it Sent to the processor 4, if the processor 4 judges that the distance value is equal to the height of the storage box 19, it means that the storage box 19 is full; A third camera is added on the side of the 1, and the third camera is connected to the processor 4 for taking pictures in the collection box and sending it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com