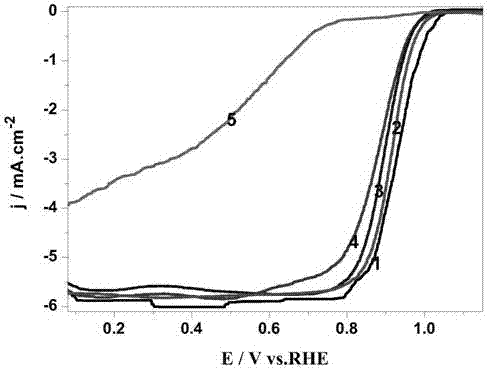

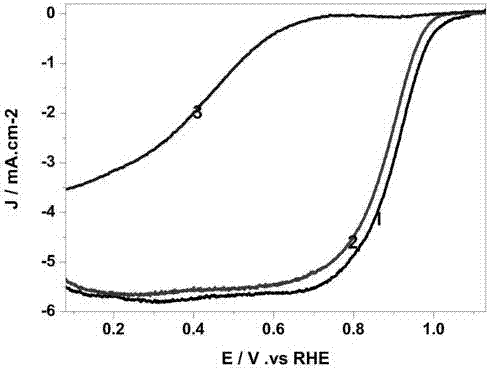

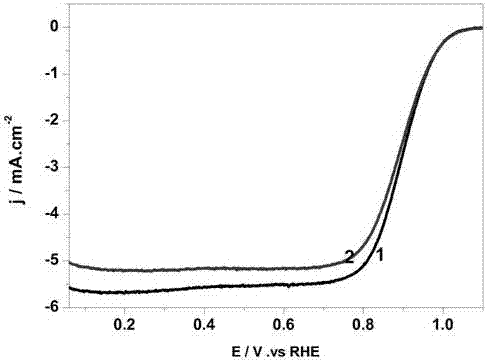

Method for preparing three-dimensional carbon framework embedded nano platinum-based alloy catalyst

A carbon skeleton, nano-platinum technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of poor stability, low utilization rate of Pt, low activity of Pt-based catalyst, etc. Effective construction, improved utilization, excellent stability and the effect of mass specific activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing an oxygen reduction three-dimensional carbon skeleton mosaic nano-platinum-cobalt alloy catalyst, the specific method steps comprising:

[0035] (1) Preparation of surfactant-modified Pt nanoparticles dispersion

[0036] According to the methanol solution of chloroplatinic acid: methanol reducing agent: polyvinylpyrrolidone mass ratio is 1: 18: 0.20, take by weighing the methanol solution of chloroplatinic acid, methanol reducing agent and polyvinylpyrrolidone; first the methanol solution of chloroplatinic acid Dissolve it in a hydrochloric acid solution with a concentration of 9mol / L, then add a methanol reducing agent to form a platinum precursor solution with a platinum mass concentration of 9.42mg / mL; then add polyvinylpyrrolidone to the methanol solution of chloroplatinic acid, and ultrasonically stir for 20 Minutes later, adjust the pH to 9-10 with a NaOH organic reducing agent solution with a concentration of 2.92mol / L, then condense and re...

Embodiment 2

[0046] A method for preparing an oxygen reduction three-dimensional carbon skeleton mosaic nano-platinum-cobalt alloy catalyst, the specific method steps comprising:

[0047] (1) Preparation of surfactant-modified Pt nanoparticles dispersion

[0048] According to the methanol solution of chloroplatinic acid: methanol reducing agent: polyvinylpyrrolidone mass ratio is 1: 10: 0.10, take by weighing the methanol solution of chloroplatinic acid, methanol reducing agent and polyvinylpyrrolidone; first the methanol solution of chloroplatinic acid Dissolve it in a hydrochloric acid solution with a concentration of 6mol / L, then add a methanol reducing agent to form a platinum precursor solution with a platinum mass concentration of 7.54mg / mL; then add polyvinylpyrrolidone to the methanol solution of chloroplatinic acid, and ultrasonically stir for 10 Minutes later, adjust the pH to 9-10 with a NaOH organic reducing agent solution with a concentration of 1.25mol / L, then condense and re...

Embodiment 3

[0056] A method for preparing an oxygen reduction three-dimensional carbon skeleton mosaic nano-platinum-cobalt alloy catalyst, the specific method steps comprising:

[0057] (1) Preparation of surfactant-modified Pt nanoparticles dispersion

[0058]According to the mass ratio of methanol solution of potassium chloroplatinite: methanol reducing agent: polyvinylpyrrolidone is 1: 30: 0.30, take by weighing the methanol solution of potassium chloroplatinite, methanol reducing agent and polyvinylpyrrolidone; The methanol solution of potassium platinate is dissolved in the concentration of 12mol / L hydrochloric acid solution, then add methanol reducing agent to form a platinum precursor solution with a platinum mass concentration of 18.84mg / mL; Add polyvinylpyrrolidone, stir ultrasonically for 30 minutes, adjust the pH to 9-10 with a NaOH organic reducing agent solution with a concentration of 4.75mol / L, condense and reflux for 5 hours, and obtain a dispersion of nano-Pt particles; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com