Manufacturing method of three-dimensional graphene/graphite-phase carbonized nitrogen and application thereof

A graphene and graphite phase technology, applied in the field of preparation of three-dimensional graphene/graphite phase nitrogen carbide, can solve problems such as low specific capacitance, and achieve the effects of low production cost, wide application range and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Disperse 40 mg of graphene oxide in 20 mL of deionized water, add 10 mg of graphite-phase carbonized nitrogen, and mix with low-temperature ultrasonic for 3 h at 10 °C, transfer the mixed solution to a stainless steel hydrothermal reaction kettle, keep it at 180 °C for 12 h, and cool naturally to room temperature to obtain a graphene / graphite phase nitrogen carbide hydrogel column, cut into slices, wash the product three times with deionized water, and freeze-dry at -40°C to obtain a three-dimensional graphene / g-C 3 N 4 .

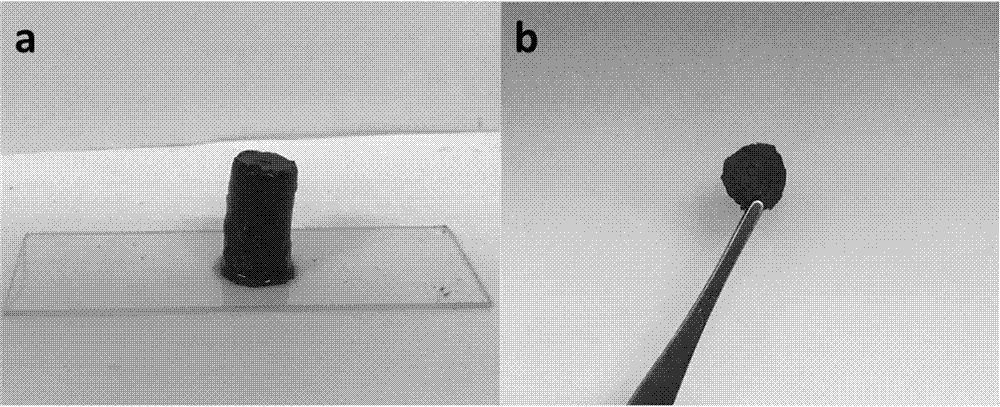

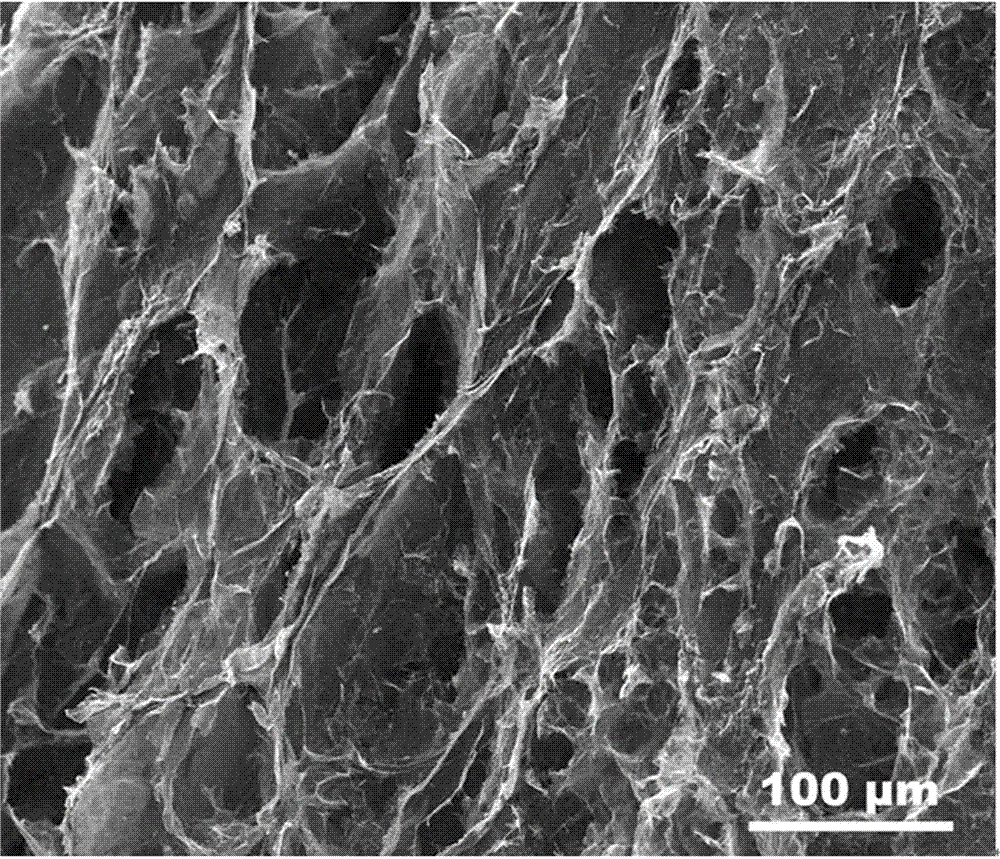

[0023] figure 1 Three-dimensional graphene / g-C prepared for embodiment 1 3 N 4 Optical photographs of the hydrogel column (a) and slice after freeze-drying (b), by figure 1 (a) (b) It can be seen that the three-dimensional graphene / g-C obtained in this example 3 N 4 The hydrogel column has a regular columnar morphology with regular edges; and the shape is well maintained after freeze-drying, and it can be directly used as an electrode materia...

Embodiment 2

[0025] Disperse 50 mg of graphene oxide in 20 mL of deionized water, add 5 mg of graphite-phase carbonized nitrogen, and mix with low-temperature ultrasonic for 3 h at 12 °C, transfer the mixed solution to a stainless steel hydrothermal reaction kettle, keep it at 160 °C for 10 h, and cool naturally Three-dimensional graphene / g-C obtained at room temperature 3 N 4 Hydrogel column, sectioned, washed with deionized water three times, freeze-dried at -40°C to obtain three-dimensional graphene / g-C 3 N 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com