Liquid metal computer

A liquid metal and computer technology, applied in the direction of computers, computing, digital computer components, etc., can solve the problems of high power consumption, slow computing speed, and large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

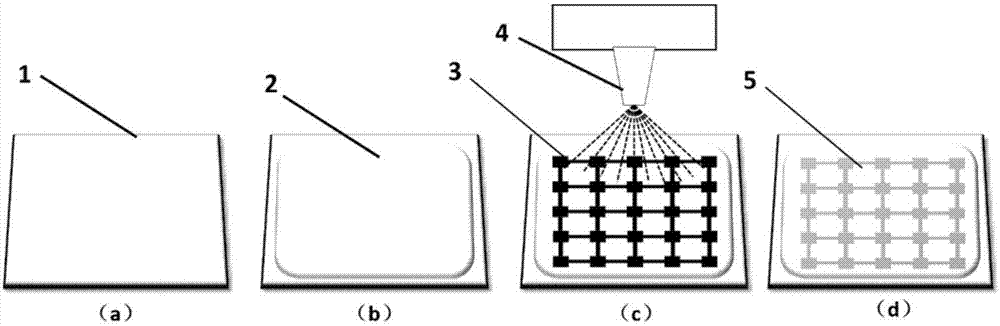

Method used

Image

Examples

Embodiment 1

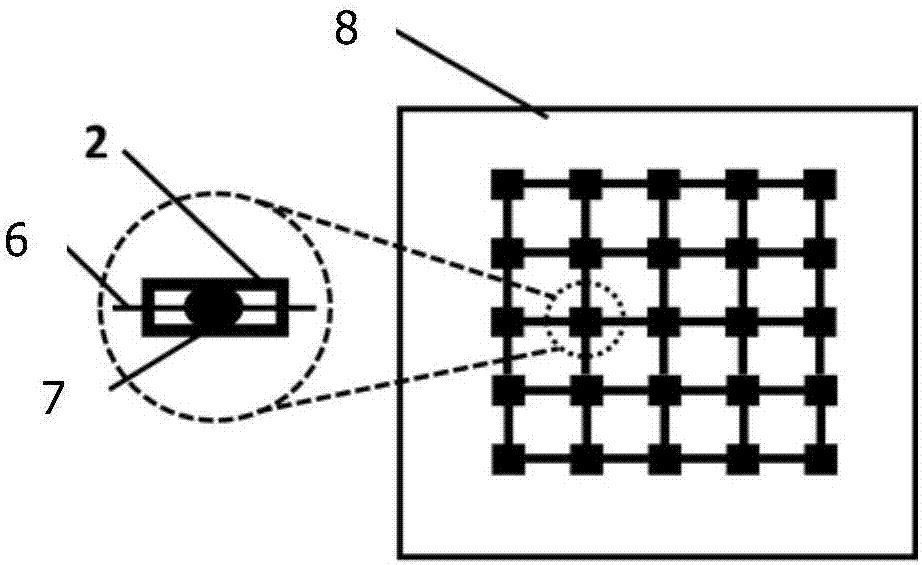

[0042] Reference attached figure 2 The basic logic device structure of the liquid metal computer of the present invention includes electrode lines 6, flexible film 2, liquid metal particles 7, etc., and multiple basic logic devices can form a simple element array 8 to perform complex functions.

Embodiment 2

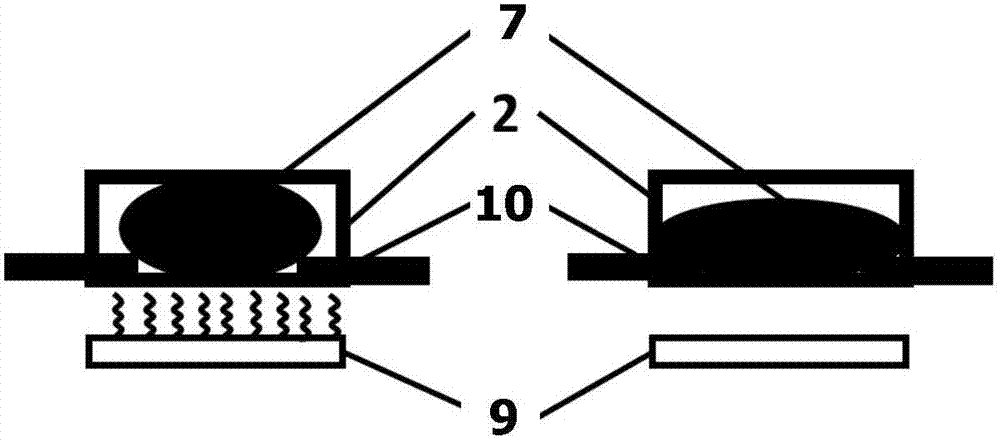

[0044] Reference attached image 3 , by adjusting the ambient temperature to realize the control scheme of solid-liquid phase transition. The liquid metal 7 is encapsulated in the flexible film 2, and a temperature regulating device, such as a cooling plate 9, is attached on the surface of the flexible film 2. Use refrigerating plate 9 to cool down, liquid metal 7 becomes solid, reduces its contact area with electrode plate 10, thereby reduces electrical conductivity; Close refrigerating plate 9, liquid metal 7 becomes liquid at normal temperature, increases its contact area with electrode plate 10 contact area, thereby improving conductivity. In addition, the liquid metal 7 with a higher melting point is selected, and the liquid metal 7 is directly energized to melt it by using the thermal effect of the current, and then it is naturally cooled and solidified when the power is turned off, so that the effect of solid-liquid phase transition can also be achieved.

Embodiment 3

[0046] Reference attached Figure 4 , a control scheme that changes the surface oxidation degree of liquid metal particles by applying an external current, and then controls its electrical conductivity. Oxidation and deoxidation of the surface of the liquid metal particles 7 are achieved by applying currents 11 in different directions. Applying a positive current 11 causes it to lose electrons, forming an oxide film 12 on the surface, and the conductivity decreases; applying a reverse current 11 makes it gain electrons, removing the surface oxide film 12, and improving the conductivity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com