Coaxial direct-current plasma nozzle based on dielectric barrier discharge

A dielectric barrier discharge and plasma technology, applied in jet propulsion devices, rocket engine devices, machines/engines, etc., can solve problems such as narrow control range, difficult nozzle atomization, insufficient mixing of fuel and oxidant jets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

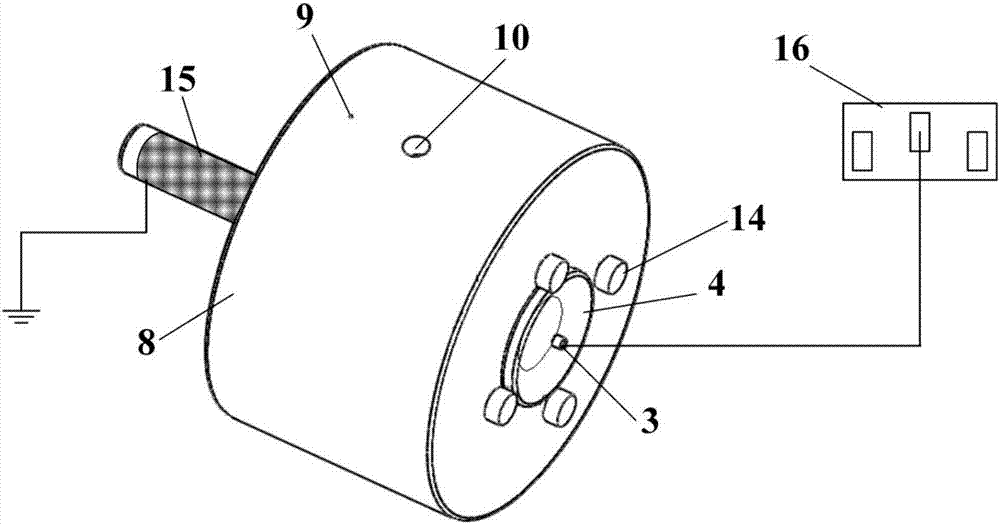

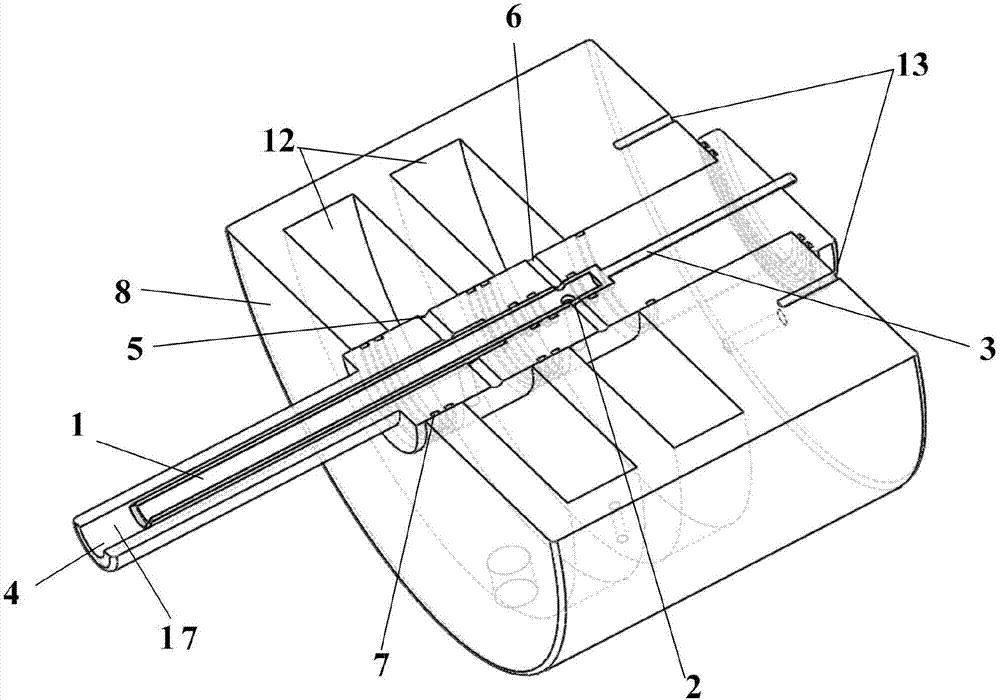

[0051] Such as figure 1 and figure 2 As shown, a coaxial direct current plasma nozzle based on dielectric barrier discharge includes a metal inner cylinder 1 , a metal rod 3 , an insulating outer cylinder 4 , a propellant chamber 8 , an outer electrode 15 and a high voltage power supply 16 .

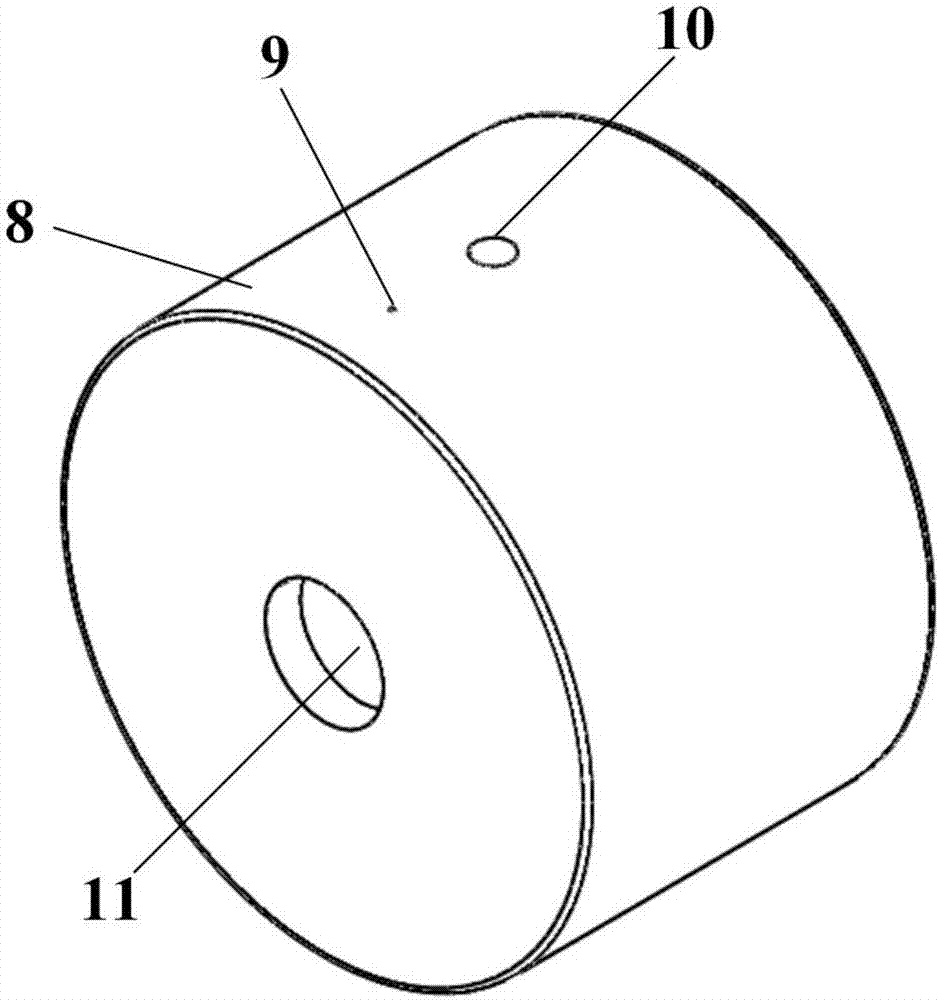

[0052] Such as image 3 and Figure 4 As shown, the propellant chamber 8 includes a main through hole 11 , two sub-chambers 12 , a propellant filling hole 10 , a monitoring hole 9 and a threaded hole 13 .

[0053] The above-mentioned main through holes are arranged along the central axis of the propellant chamber.

[0054] The two sub-cavities are parallel to each other and communicate with the main through hole.

[0055] The two sub-chambers are a propellant Y storage chamber 121 and a propellant X storage chamber 122, wherein t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com