Tunnel boring machine (TBM) cutter head pressurizing freeing hydraulic control system

A technology of hydraulic control system and cutter head, which is applied in mining equipment, tunnels, earth-moving drilling, etc., can solve the problems of stuck driving and getting out of trouble.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

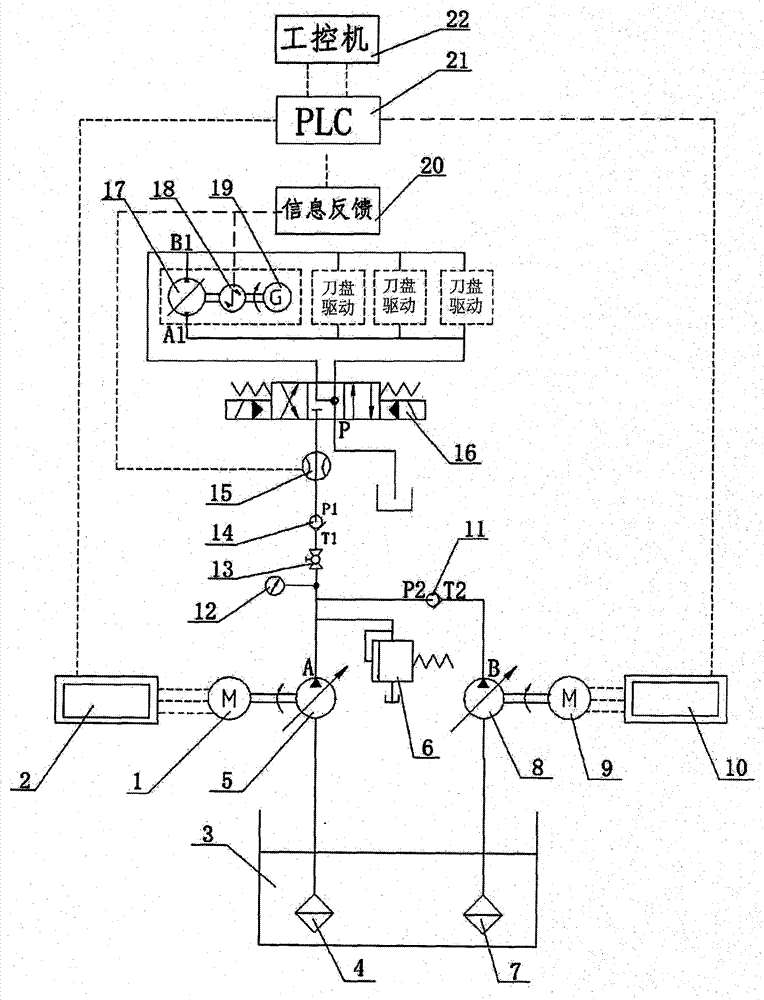

[0020] Embodiment 1: A hydraulic control system for pressurization and escape of a TBM cutterhead, see figure 1 , including the control assembly, the cutter head drive assembly, the main control oil circuit and the booster control oil circuit.

[0021] The control assembly includes a sequentially connected industrial computer 22, a PLC control unit 21, and an information feedback unit 20; the cutter head drive assembly includes a hydraulic motor 17, a torque sensor 18, and a reducer 19 that are connected correspondingly to the TBM cutter head, and the torque sensor 18 and information feedback The unit 20 corresponds to the electrical connection; among them, the cutter head drive assembly can be set in multiple groups according to the specific situation. In this embodiment, four groups of cutter head drive assemblies are provided, and the hydraulic motors in each group are connected in parallel to drive the TBM cutter head to rotate synchronously.

[0022] The main control oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com