Rear steering drive axle assembly of forklift

A drive axle assembly and rear steering technology, which is applied to vehicle parts, control devices, transportation and packaging, etc., can solve the problems of no limited slip self-locking, off-road performance of the vehicle, poor climbing ability of driving force, and poor work efficiency, etc. Problems, to achieve the effect of improving work efficiency and off-road performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

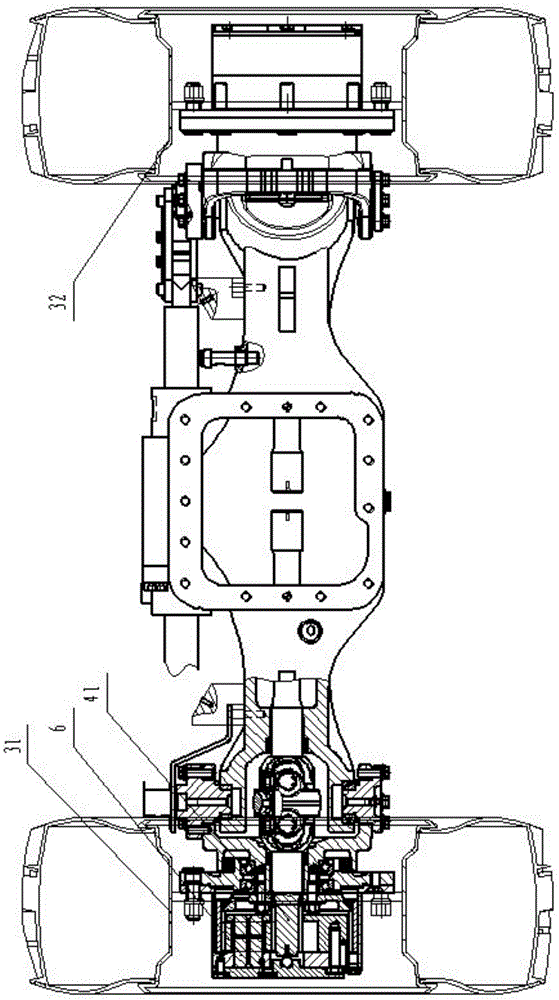

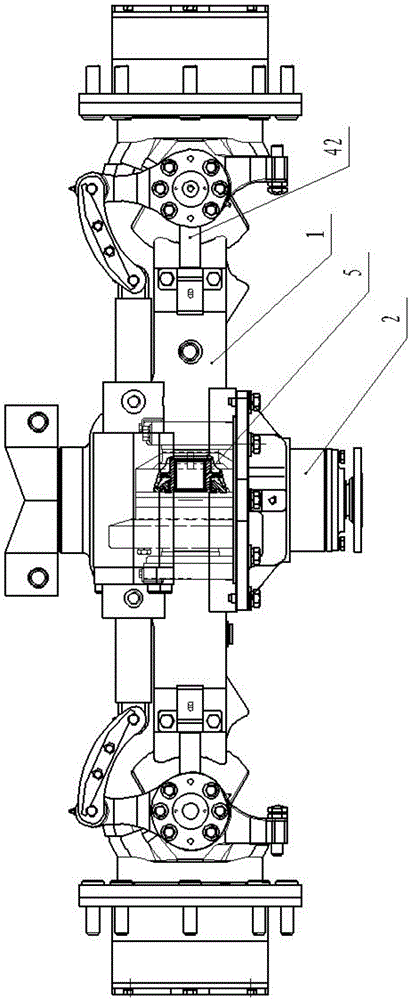

[0019] Forklift rear steering drive axle assembly, such as figure 1 , figure 2 As shown, it includes the bridge body assembly 1, the main reducer 2 is installed on the bridge body assembly 1, and the left and right half shaft assemblies connected with the left and right hubs 31 and 32 are respectively arranged on both sides of the bridge body assembly 1 41, 42, a differential lock 5 is installed in the main reducer 1, and the differential lock 5 is connected with the left and right half shaft assemblies 41, 42 through splines.

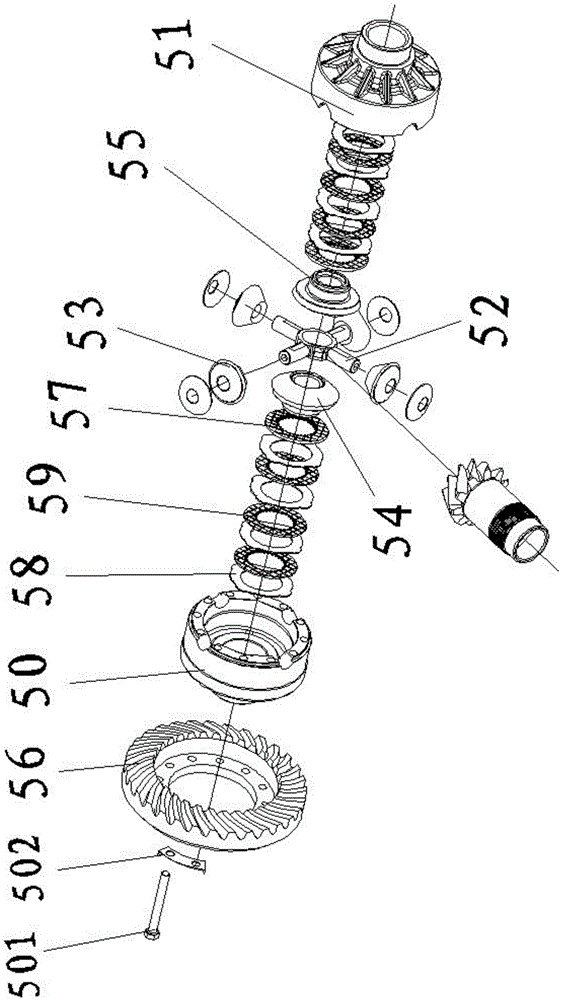

[0020] Among them, such as image 3 As shown, the differential lock 5 comprises a left differential lock housing 50, a right differential lock housing 51 and a cross shaft 52 fixed between the left differential lock housing 50 and the right differential lock housing 51, the up, down, left, and right sides of the cross shaft 52 Planetary gears 53 are provided on the four shafts, and spherical washers are provided on the planetary gears 53. In this em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com