Body skeleton of assaulting vehicle

An assault vehicle and skeleton technology, applied in the direction of load-bearing body structure, vehicle components, superstructure, etc., can solve problems such as difficulty in meeting practical applications, non-uniform materials of body frame components, etc., and achieve off-road performance and passability. Standardized and easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

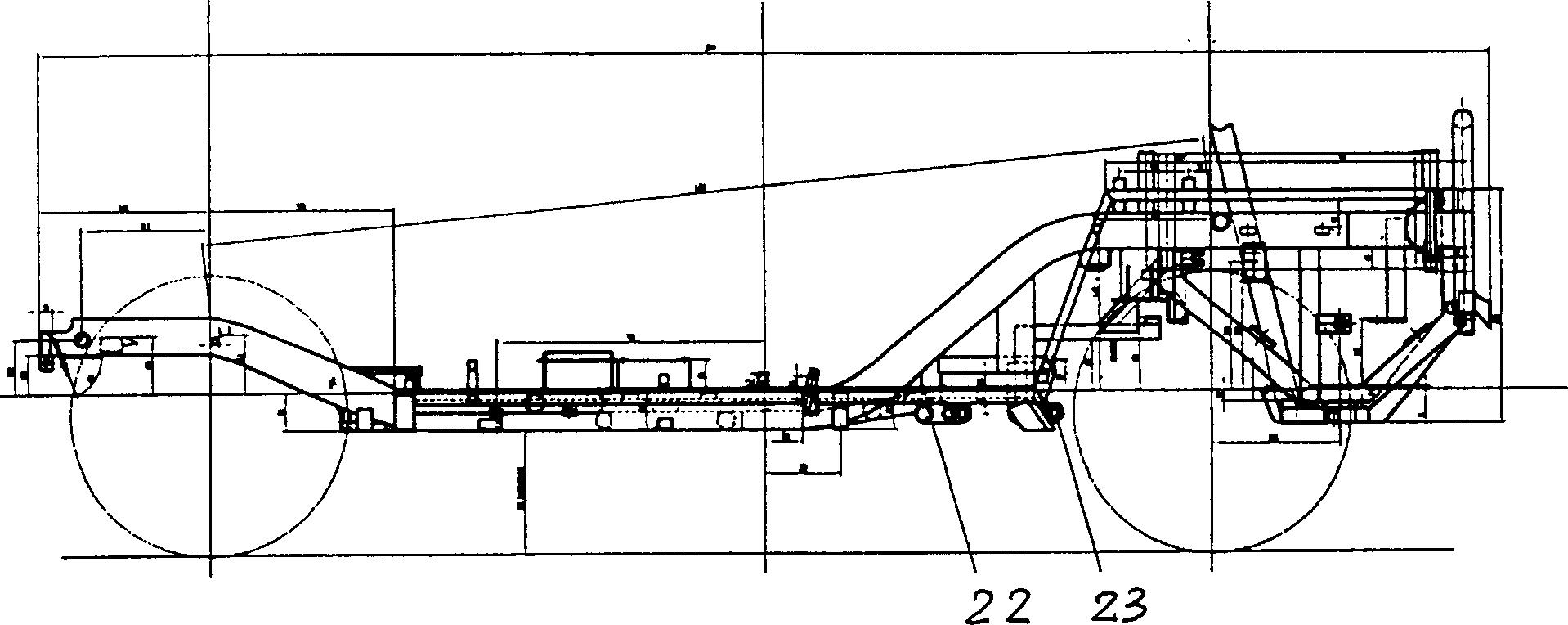

[0025] The specific embodiments of the present invention, combined with the attached Figure 1 to 15 The details are as follows:

[0026]The body frame of the assault vehicle referred to in the present invention is composed of a bottom frame, a front frame, a top frame and a rear frame. The body frame is designed as a whole by adopting a uniform cross-section and tubular steel truss structure. The bottom frame is made up of multiple beams, cross beams and support beams to weld the left longitudinal beam 1 and the right longitudinal beam 2 into a whole. The first beam 3 is arranged at the front of the left and right longitudinal beams 1, 2, and its ends are connected to the left and right longitudinal beams. The right longitudinal beams 1 and 2 are connected, the front suspension front support beam assembly 20 is arranged on the first cross beam 3, the front suspension rear support beam assembly 21 is arranged on the second cross beam, the diagonal cross beam 8 and the diagonal cros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com