Boiler primary air pulverized coal flow gasification device for boiler ignition and stable combustion

A boiler ignition and gasification device technology, which is applied in the gasification of granular/powder fuel, the combustion of gaseous fuel and powder fuel, and the manufacture of combustible gas, etc., can solve the problems of high failure rate, huge equipment, complex system, etc. Achieve the effect of enhanced peak shaving capability, sufficient response, and reduced minimum stable combustion load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

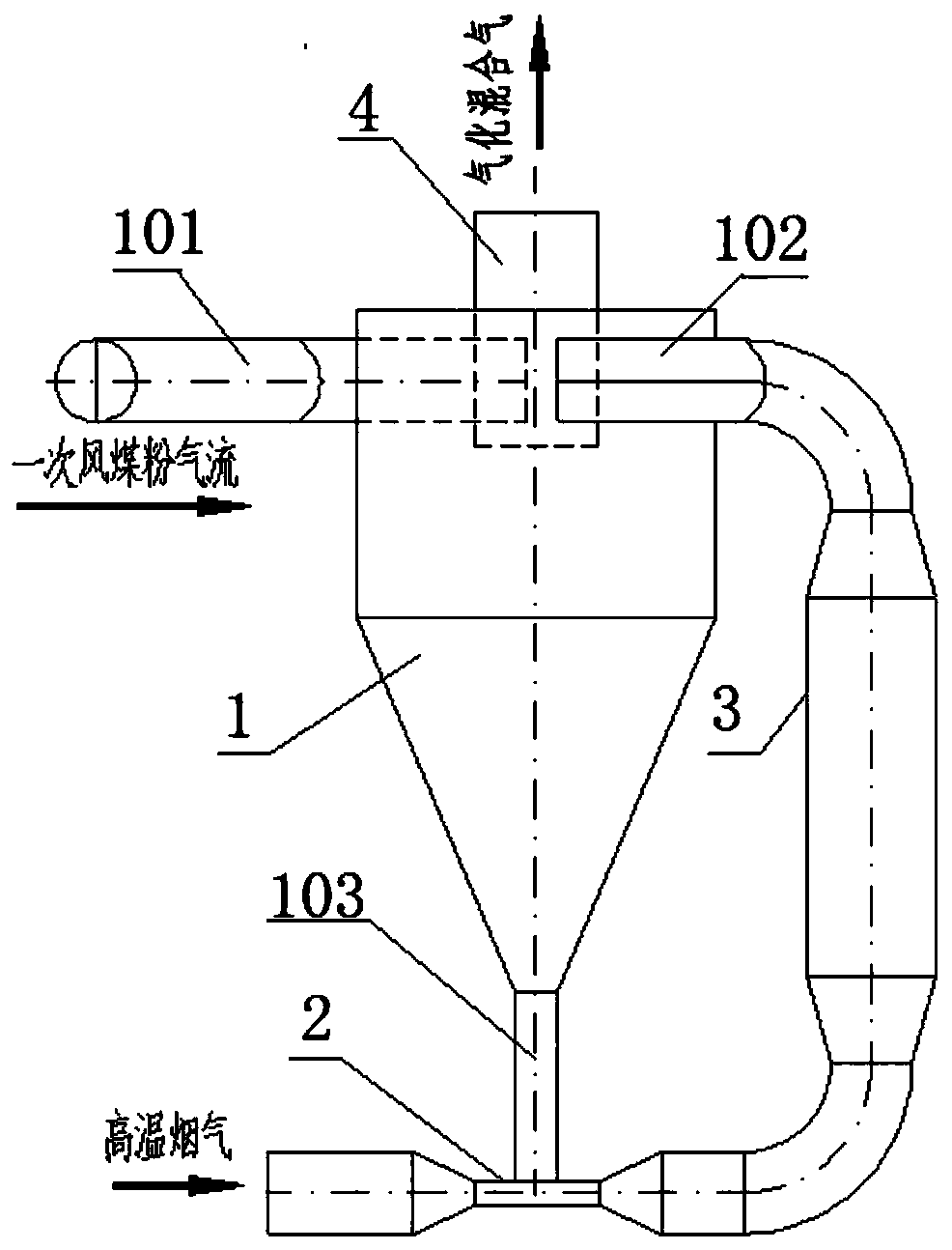

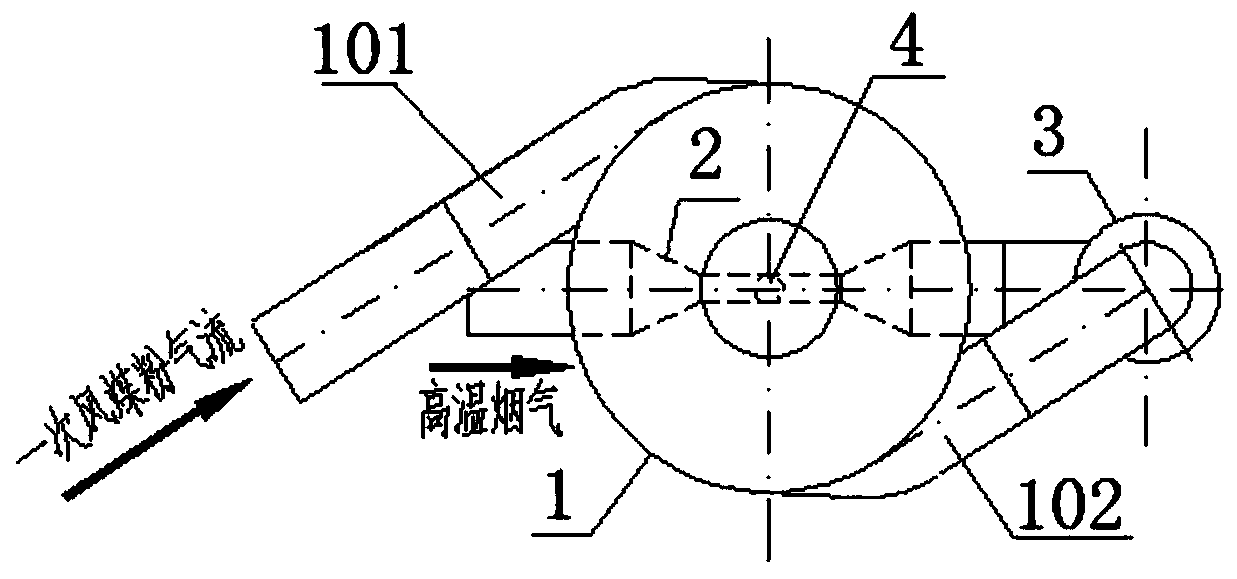

[0021] see figure 1 , figure 2 , a boiler primary air pulverized coal airflow gasification device for boiler ignition and stable combustion, including a cyclone separator 1, a Laval mixer 2, a gasification reactor 3, and a central pipe 4 arranged on the top of the cyclone separator 1 ;

[0022] The upper part of the cyclone separator 1 is tangentially symmetrically provided with a first inlet pipe 101 and a second inlet pipe 102, and the second inlet pipe 102 communicates with the outlet of the gasification reactor 3; the bottom of the cyclone separator 1 is provided with a straight pipe 103 It communicates with the throat of the Laval mixer 2; the outlet side of the Laval mixer 2 communicates with the inlet of the gasification reactor 3 through a conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com