High-temperature and salt-resistant high-density spacer fluid and preparation method thereof

A high-density, high-temperature-resistant technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of suspension capacity limitation and suspension capacity weakening, and achieve low water loss, high fluidity, and compatibility good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

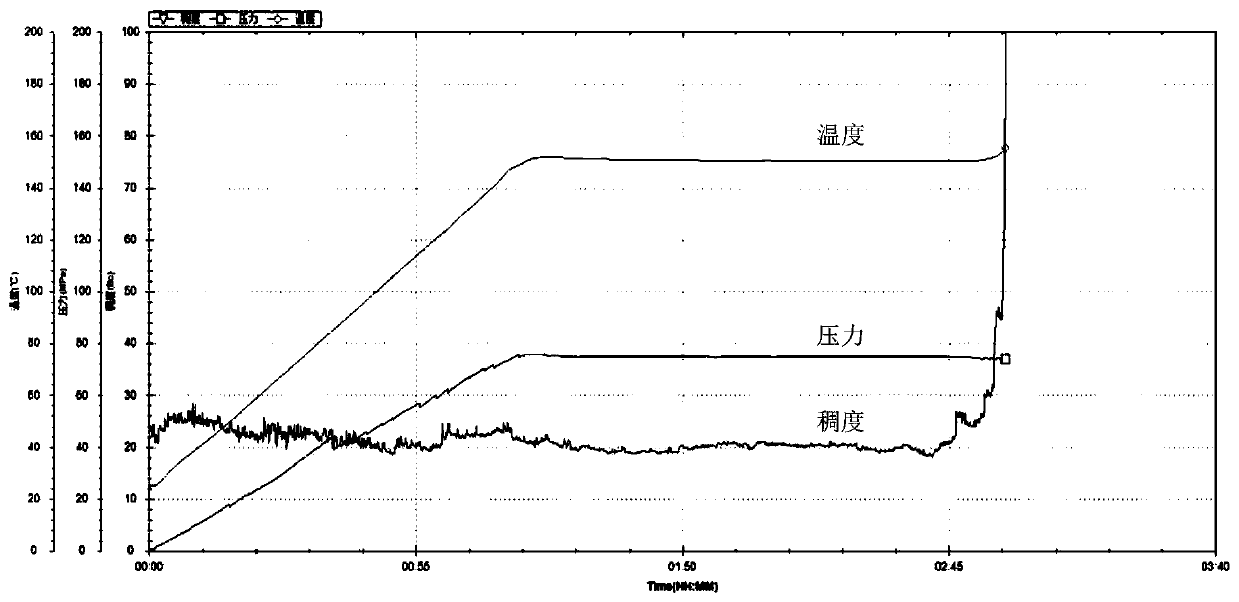

Embodiment 1

[0028] Slowly add 2 parts of suspension stabilizer to 100 parts of water, mix evenly, stir in a Waring mixer at a speed of 4000r / min for 1.5min, stop stirring, hydrate for 8min, then slowly add 195 parts of weighting agent, and then add 7 1 part of water loss reducer, 5 parts of cleaning agent, 1 part of retarder and 18 parts of sodium chloride, mix well and then stir at 2000r / min for 1min, finally add 0.2 part of defoamer, stir evenly to get the density 2.0g / cm 3 High-temperature and salt-resistant high-density spacer fluid.

[0029] Among them, the weighting agent consists of 180 parts with an average particle size of 100 μm and a density of 5.0 g / cm 3 The iron ore powder and 15 parts have an average particle size of 1.8μm and a density of 5.05g / cm 3 The micro manganese composition; the defoamer is a mixture of simethicone oil and tributyl phosphate in a weight ratio of 1:0.2.

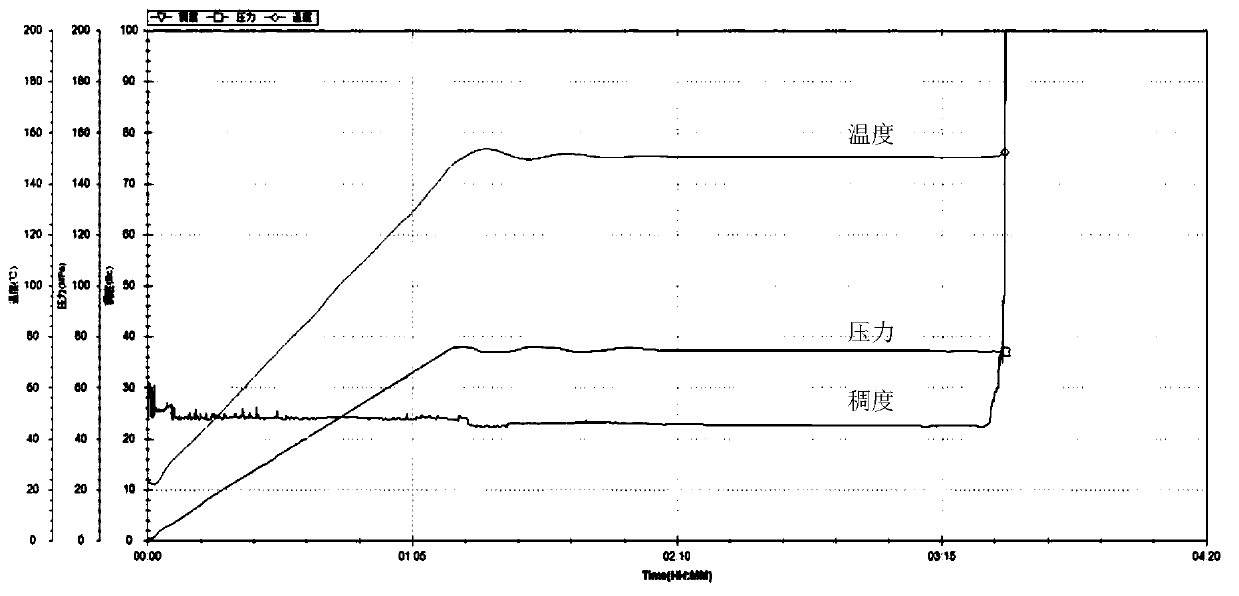

Embodiment 2

[0031] Slowly add 1.6 parts of suspension stabilizer to 100 parts of water, mix evenly, stir in a Waring mixer at a speed of 4000r / min for 1.5min, stop stirring, hydrate for 8min, then slowly add 235 parts of weighting agent, and then add 8 1 part of fluid loss reducer, 6 parts of cleaning agent, 2 parts of retarder and 22 parts of sodium chloride, mix well and then stir at 2000r / min for 1min, finally add 0.3 part of defoamer, stir evenly to get the density 2.20g / cm 3 High-temperature and salt-resistant high-density spacer fluid.

[0032] Among them, the weighting agent consists of 215 parts with an average particle size of 100 μm and a density of 5.05 g / cm 3Iron ore powder and 20 parts with an average particle size of 1.6μm and a density of 5.05g / cm 3 The micro manganese composition; the defoamer is a mixture of simethicone oil and tributyl phosphate in a weight ratio of 1:0.3.

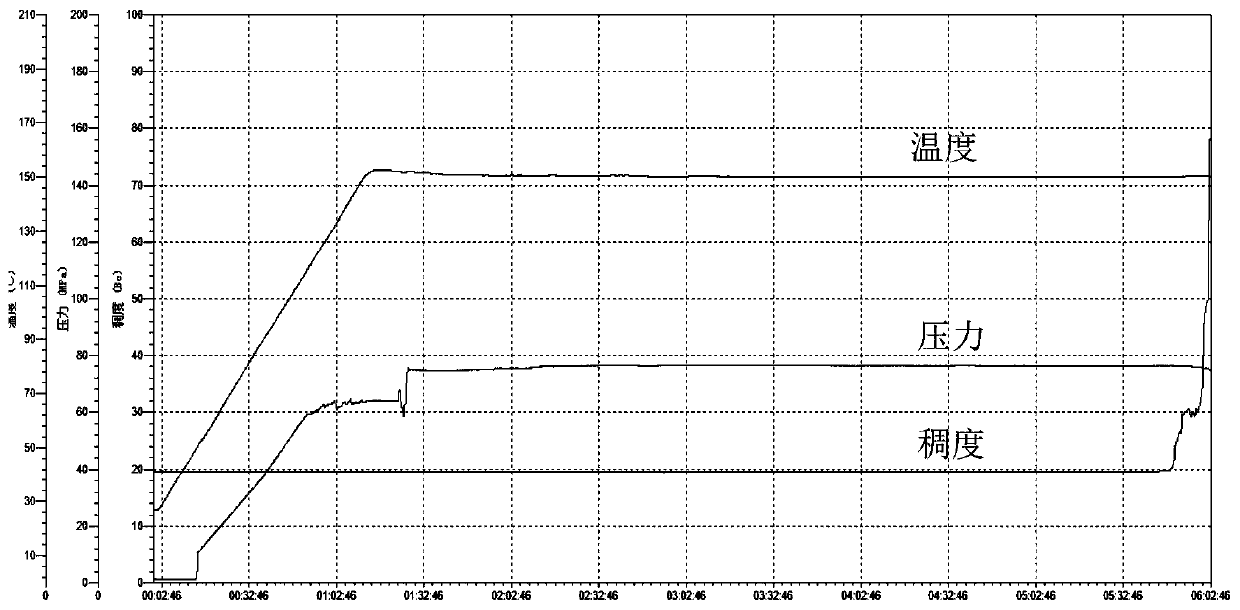

Embodiment 3

[0034] First, slowly add 1.4 parts of suspension stabilizer to 100 parts of water, mix evenly, stir in a Waring mixer at a speed of 4000r / min for 1.5min, stop stirring, hydrate for 8min, then slowly add 270 parts of weighting agent, and then add 8 parts of fluid loss reducer, 7 parts of cleaning agent, 2 parts of retarder and 36 parts of sodium chloride, after mixing evenly, stir at a speed of 2000r / min for 1min, and finally add 0.4 parts of defoamer, stir evenly, and get The density is 2.40g / cm 3 High-temperature and salt-resistant high-density spacer fluid.

[0035] Among them, the weighting agent consists of 90 parts with an average particle size of 100 μm and a density of 5.0 g / cm 3 Iron ore powder, 160 parts with an average particle size of 140μm and a density of 7.0g / cm 3 Iron ore powder and 20 parts with an average particle size of 1.4μm and a density of 5.05g / cm 3 The micro manganese composition; the defoamer is a mixture of simethicone oil and tributyl phosphate in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com