A kind of high-performance rosmarinic acid molecular surface imprinted particles and preparation method thereof

A technology of rosmarinic acid and surface imprinting, applied in chemical instruments and methods, other chemical processes, alkali metal compounds, etc., can solve the problem of difficult separation of components with similar structures, low separation efficiency and recovery rate, and low purity of extracted drugs and other problems, to achieve the effect of specific recognition selectivity, simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

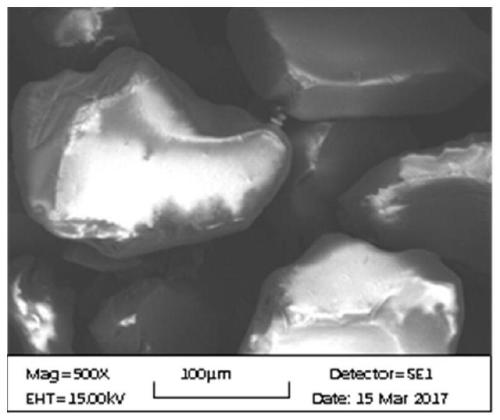

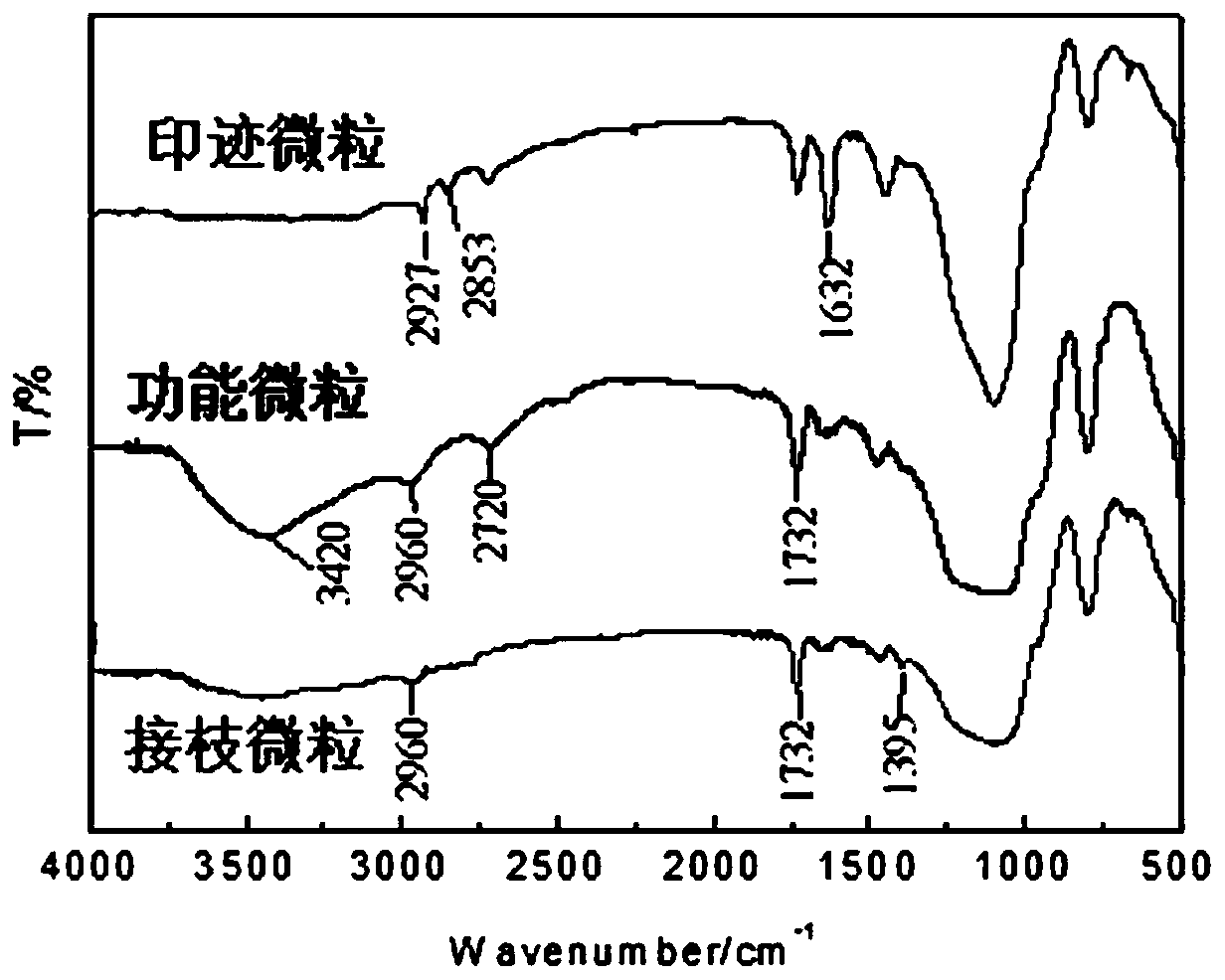

[0028] Step 1: Preparation of Grafted Microparticles

[0029] Pour 3g of AMPS-modified silica gel particles, 30mL of monomeric DMAEMA and 120mL of distilled water into a four-necked flask, exhaust the air inside the four-necked flask with nitrogen, then add 0.3g of ammonium persulfate (initiator), at 50°C Reacting at high temperature for 6 hours, the monomer DMAEMA is attached to the surface of silica gel particles, thereby preparing grafted particles.

[0030] In this step, the modification process of the silica gel particles modified by AMPS is as follows:

[0031] Weigh 10g of silica gel particles into a four-neck flask, add 100mL of distilled water, then add 10mL of AMPS, react at 50°C for 24 hours, after the reaction, suction filter (wash to neutral) to obtain modified particles.

[0032] The reason why we choose the silica gel particles modified by AMPS is that after the silica gel particles are modified by AMPS, a large amount of amino groups can be introduced into the...

Embodiment 2

[0041] Step 1: Preparation of Grafted Microparticles

[0042] 2.25g of silica gel particles modified by AMPS, 25mL of monomer DMA EMA and 125mL of distilled water were poured into a four-necked flask, and the air in the four-necked flask was purged with nitrogen, then 2.5g of ammonium persulfate (initiator) was added, and the React at 35° C. for 6 hours, so that the monomer DMAEMA is attached to the surface of the silica gel particles, thereby preparing grafted particles.

[0043] In this example, the silica gel particles modified by AMPS are the same as those in Example 1.

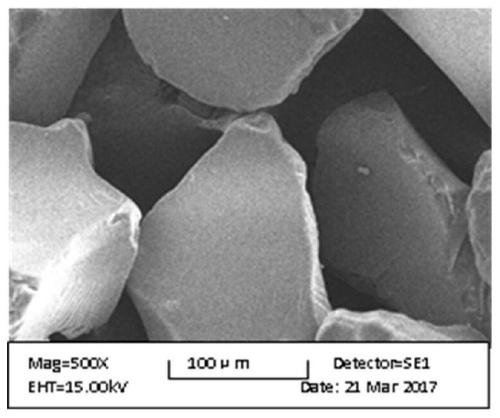

[0044] Step 2: Preparation of positively charged functional particles

[0045] Dissolve 1.2 g of 2-chloroethylamine hydrochloride (a quaternizing agent) in 150 mL of water, adjust the pH to 7.0, then add 1.5 g of grafted microparticles, and react at a temperature of 60 ° C for 14 h to make the tertiary The amine group undergoes a quaternization reaction with the chloroalkyl group of the quaternizing age...

Embodiment 3

[0052] Step 1: Preparation of Grafted Microparticles

[0053] 2.25g of silica gel particles modified by AMPS, 25mL of monomer DMA EMA and 125mL of distilled water were poured into a four-necked flask, and the air inside the four-necked flask was purged with nitrogen, then 0.25g of ammonium persulfate (initiator) was added, and React at 35° C. for 6 hours, so that the monomer DMAEMA is attached to the surface of the silica gel particles, thereby preparing grafted particles.

[0054] In this example, the silica gel particles modified by AMPS are the same as those in Example 1.

[0055] Step 2: Preparation of positively charged functional particles

[0056] Dissolve 1.2g of 2-chloroethylamine hydrochloride (a quaternizing agent) in 150mL of water, adjust the pH to 7.0, then add 1.5g of grafted particles, and react at 60°C for 14 hours to make the tertiary amino group of the grafted particles The group undergoes a quaternization reaction with the chloroalkyl group of the quatern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com