Mobile phone middle frame and production process of mobile phone frame comprising same

A mobile phone middle frame and production process technology, which is applied in the direction of telephone structure, telephone communication, electrical components, etc., can solve the problems of poor combination stability, low processing efficiency, and difficulty in effective combination, so as to ensure connection stability and improve Production efficiency and the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

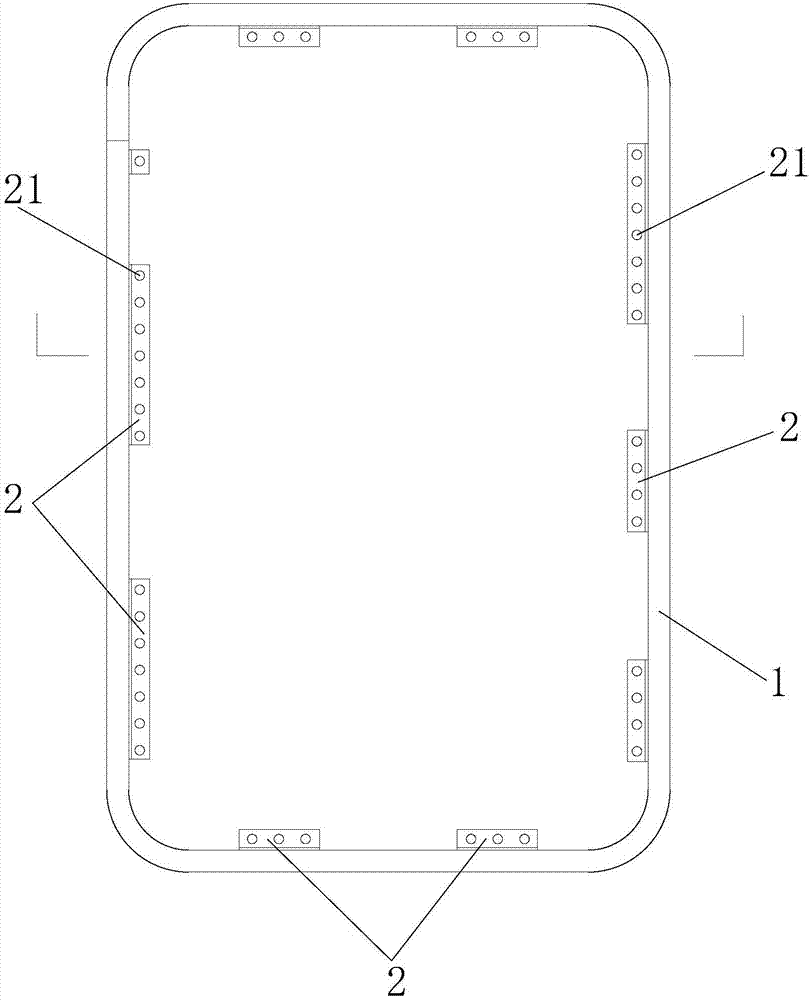

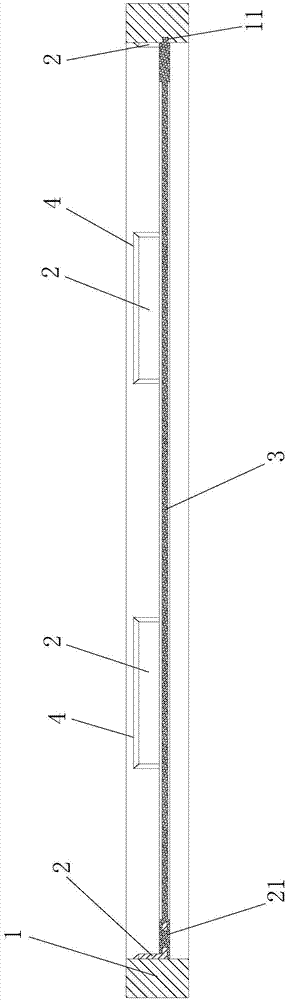

[0029] Such as Figure 1-Figure 2 As shown, the present invention is a middle frame of a mobile phone. The middle frame of the mobile phone includes a metal frame 1 formed by butting the ends of the bent metal strips. The cross section of the metal strips is rectangular; the metal strips can be stainless steel strips or aluminum strips. Alloy strips or other metal strips; several metal support sheets 2 are welded at intervals on the inner surface of the metal frame 1. Fitting and the periphery of the fitting surface is fully welded, and the other side of the metal support sheet 2 is perpendicular to the inner surface of the metal frame 1 . The material thickness of the metal support sheet 2 is about 0.3mm, and its length can be equal or unequal, and it can be set according to needs;

[0030] The middle frame of the mobile phone of the present inv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile load | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com