Control method of eliminating yield point elongation at front part and rear part of weld joint of cold-rolled strip steel

A technology of yield platform and control method, applied in the field of cold-rolled strip steel production control, can solve the problems of large waste of cutting waste, scratched steel plate surface, strip accident, etc., to ensure product quality, improve production efficiency, and reduce quality objections Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

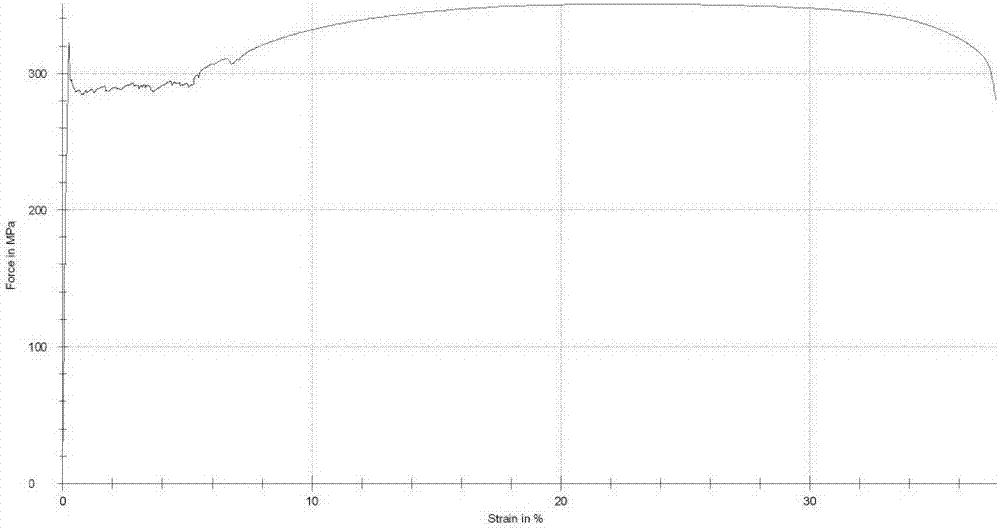

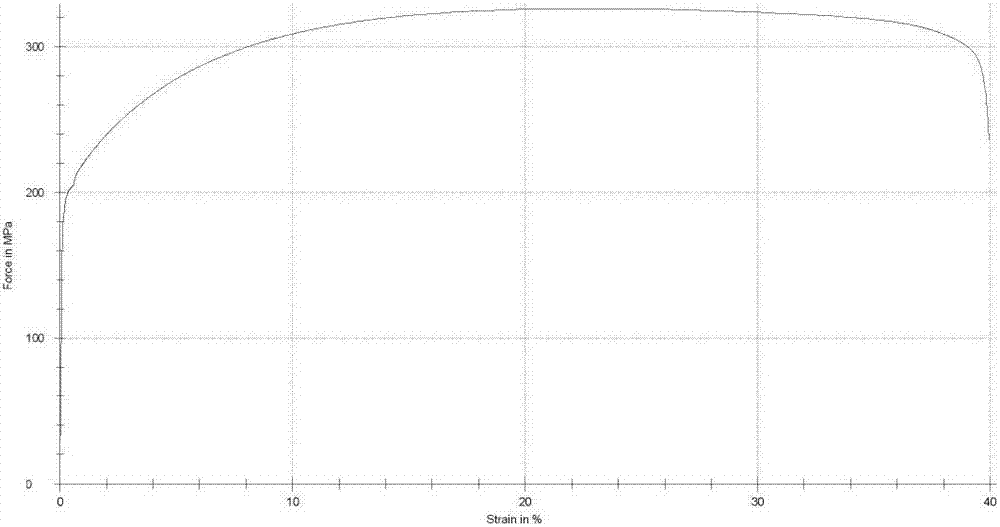

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below through embodiment.

[0018] A control method for eliminating the yield platform before and after the cold-rolled strip weld comprises the following steps:

[0019] ① During the continuous production of strip steel, the operator determines the minimum number of waste cutting knives at the end of the strip and the minimum number of waste cutting knives at the head according to the speed of the weld pass through the skin pass machine according to the following formula, and then sets the minimum waste cutting at the end of the strip at the exit sub-coil The number of knives and the minimum number of waste cutting knives:

[0020] Y1≥ROUNDUP{(0.58595+0.01384*X) / 0.45,0};

[0021] Y2≥ROUNDUP{(5.48925-0.04198*X+0.000346*X 2 ) / 0.45,0};

[0022] Among them: Y1 is the minimum number of waste cutting knives at the tail, Y2 is the minimum number of waste cutting knives at the head, X is the speed of the weld pass pass levelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com