Waste recovery equipment

A technology for recycling equipment and equipment, which is applied in the direction of lighting and heating equipment, solid separation, dryers, etc., can solve the problems of secondary pollution of groundwater, inconvenience of unified treatment, large air pollution, etc., achieve uniform heating area and ensure screening area, does not affect the effect of processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

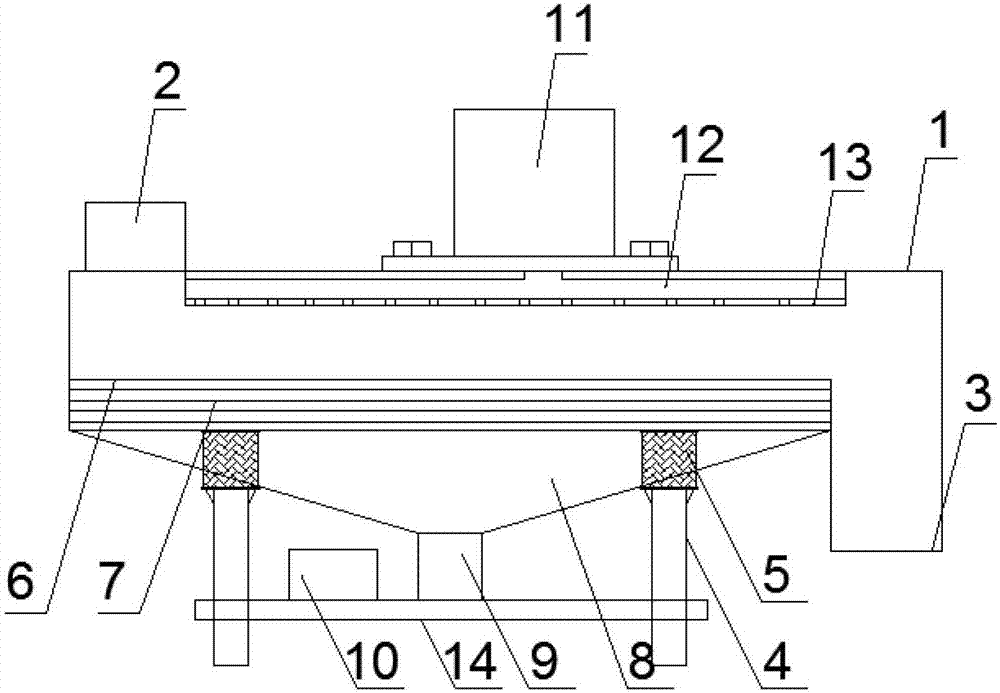

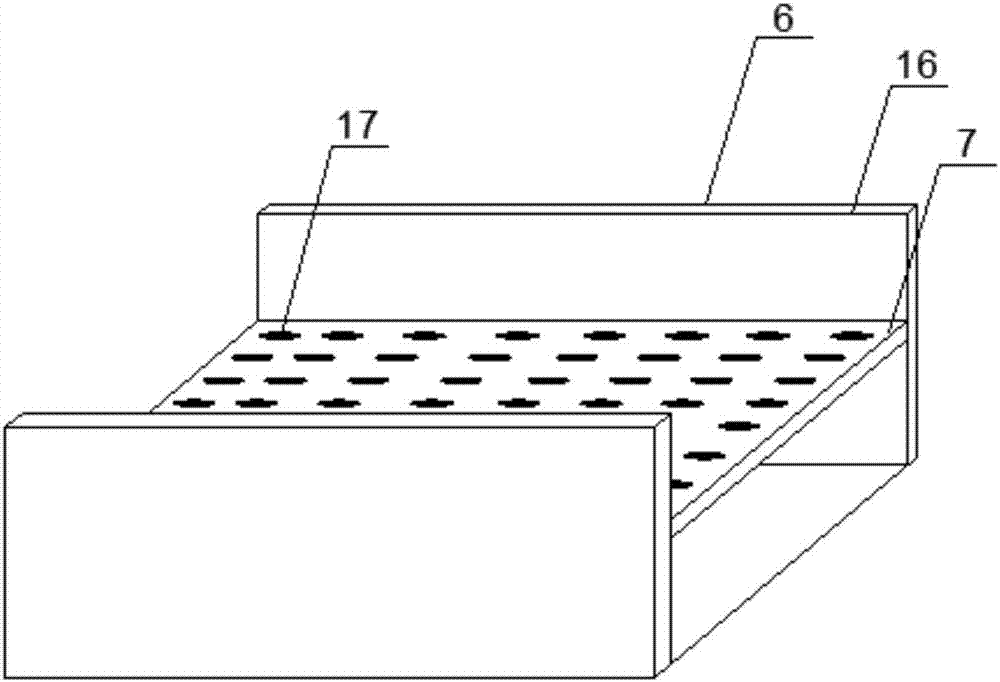

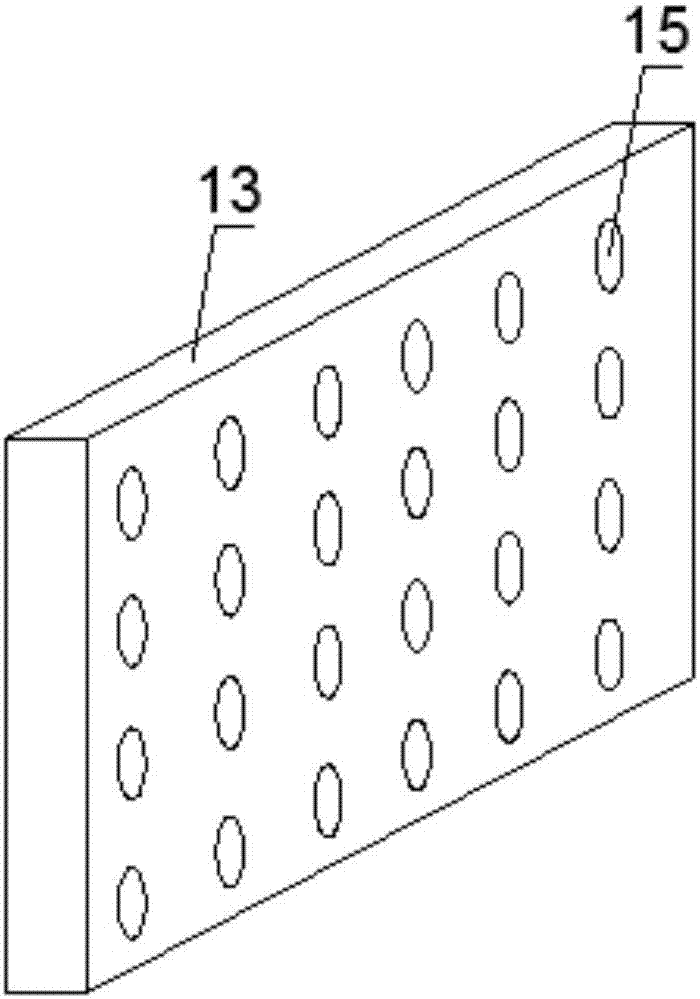

[0032] A kind of garbage recovery equipment, comprising a device body 1, one end surface of the device body 1 is provided with a material inlet 2, and the bottom surface of the other end of the device body 1 is provided with a discharge port 3, the device body 1 is supported by two sets of brackets 4, two groups Also be provided with fixed plate 14 between support 4, the surface of fixed plate 14 is provided with vibrating motor 10, and one end of vibrating motor 10 connects screen cloth 7 inside sieve box 6, and both sides of sieve box 6 are all provided with baffle plate 16, The surface of the screen cloth 7 is provided with a sieve hole 17, and a damping spring 5 is also provided between the screen box 6 and the support 4. The bottom end of the screen box 6 is provided with a funnel 8, and the bottom end of the funnel 8 is provided with a collection device 9. One side of the feed port 2 is provided with a hot air blower 11, and one end of the hot air blower 11 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com