Processing equipment for removing impurities from Porphyra haitanensis and application technology

A processing equipment and technology of laver, applied in the direction of climate change adaptation, separation of solids from solids by air flow, magnetic separation, etc., can solve the problems of poor production capacity, single variety, low grade, etc., and improve the efficiency of impurity removal. , the effect of reducing the rate of mis-picking and the rate of mis-cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

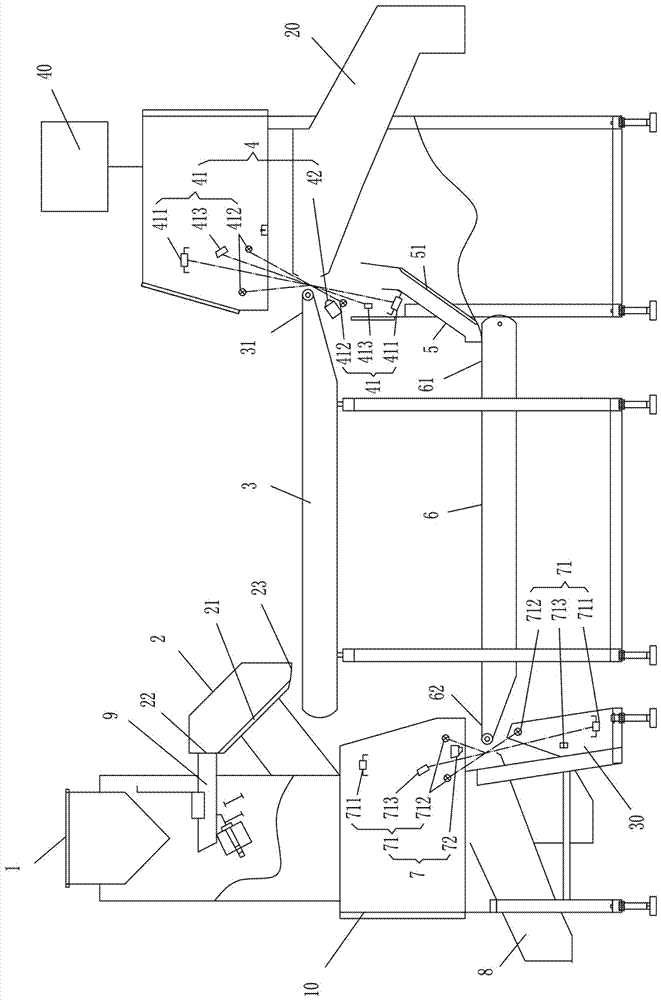

[0021] Such as figure 1 Shown, a kind of altar laver removal processing equipment, it comprises feed hopper 1, upper chute 2, the first belt conveying mechanism 3, the first sorting device 4, lower chute 5, the second chute arranged by altar laver transmission sequence Two belt conveyors 6, the second sorting device 7 and a hopper 8, the feed hopper 1 is positioned on the frame 10 above the first belt conveyor 3, the gap between the feed hopper 1 and the upper chute 2 A vibrating hopper 9 is installed between them, and the upper chute 2 is obliquely installed on the frame 10 between the vibrating hopper 9 and the first belt conveyor mechanism 3, and a magnetic element 21 is laid in the upper chute 2, and the upper chute 2 The feed end 22 is opposite to the discharge end of the vibrating hopper 9, and the discharge end 23 of the upper chute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com