A kind of molybdenum disulfide/carbon fiber network flexible electrode and its preparation method and application

A molybdenum disulfide, flexible electrode technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of inability to meet the requirements of flexible lithium-ion batteries, cumbersome preparation process, poor electrode flexibility, etc., and is suitable for mass production. Simplified process steps, not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

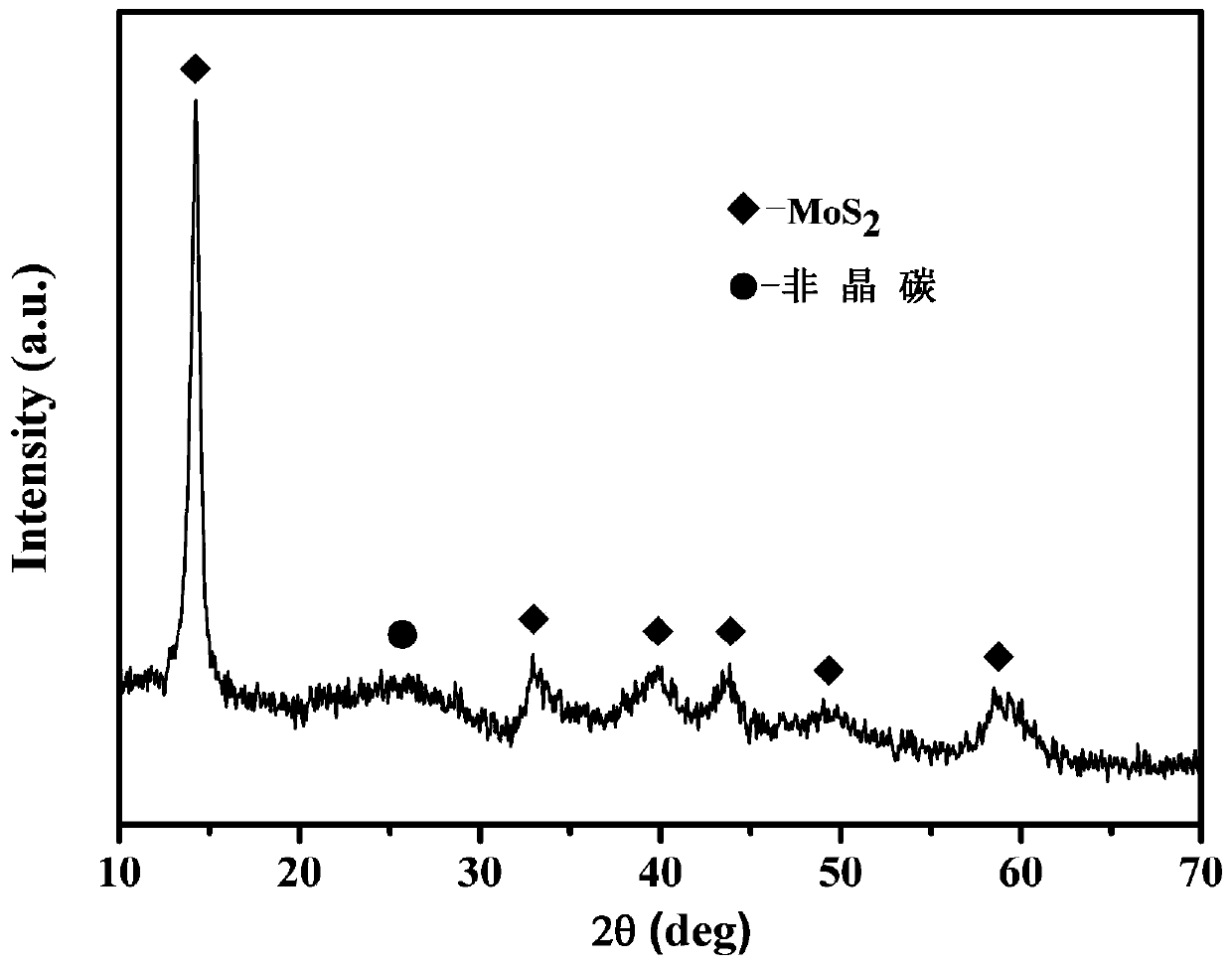

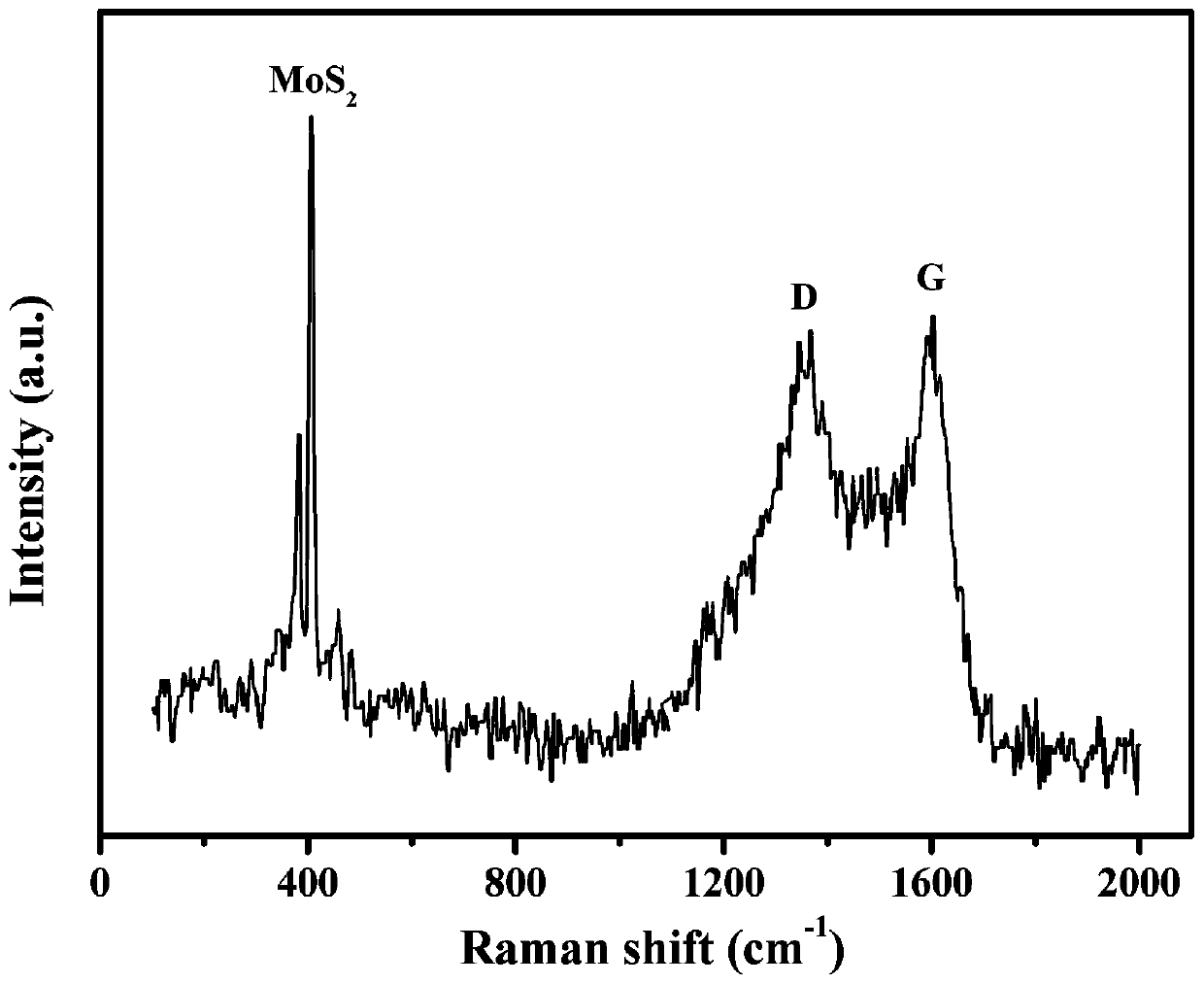

Embodiment 1

[0046] Weigh 0.1960g of ammonium molybdate and 0.1903g of thiourea, add them to 5mL of deionized water successively, carry out magnetic stirring at a stirring speed of 200r / min to dissolve them into a solution, and then sonicate for 15min with an ultrasonic machine with a power of 320W Mix it well. Take the pre-cut Hangzhou Fuyang Xinxing slow-speed quantitative filter paper disk with a diameter of 19mm and immerse it in the above mixture, and use an ultrasonic device with a power of 320W for 30 minutes, and then in 10 -1 Pa stand in a vacuum box for 12 hours. The above-mentioned fully soaked filter paper discs were frozen in a refrigerator for 12 hours, and then placed in a freeze dryer at -50°C for 30 hours in vacuum to obtain a filter paper disc containing a mixture of molybdenum source and sulfur source airgel. Then put it in a porcelain boat, put the porcelain boat into the constant temperature zone of the tube furnace, first pass in 300mL / min argon gas for 30min to remo...

Embodiment 2

[0050] Weigh 0.2059g of sodium molybdate and 0.3806g of thiourea, add them to 2mL of deionized water successively, carry out magnetic stirring at a stirring speed of 200r / min to dissolve them into a solution, and then sonicate them with a 320W ultrasonic machine for 15min Mix it well. Take the pre-cut Hangzhou Fuyang Xinxing medium-speed quantitative filter paper disk with a diameter of 14mm and immerse it in the above mixture, and use an ultrasonic device with a power of 320W for 30 minutes, and then in 10 -1 Pa stand in a vacuum box for 12 hours. The above-mentioned fully soaked filter paper disks were frozen in a refrigerator for 12 hours, and then placed in a freeze dryer at -80°C for 24 hours in vacuum to obtain a filter paper disk containing a mixture of molybdenum source and sulfur source airgel. Then put it in a porcelain boat, put the porcelain boat into the constant temperature zone of the tube furnace, first pass in 500mL / min argon gas for 20min to remove the air, ...

Embodiment 3

[0053] Weigh 0.1960g of ammonium molybdate and 0.1878g of thioacetamide, add them to 3mL of deionized water successively, carry out magnetic stirring at a stirring speed of 200r / min to dissolve them into a solution, and then use a 320W ultrasonic Sonicate for 15 minutes to make it evenly mixed. Take the pre-cut Hangzhou Fuyang Xinxing slow quantitative filter paper disk with a diameter of 14mm and immerse it in the above mixture, sonicate with a power 320W ultrasonic machine for 30min, then in 10 -1 Pa stand in a vacuum box for 12 hours. The above-mentioned fully soaked filter paper discs were frozen in a refrigerator for 12 hours, and then placed in a freeze dryer at -50°C for 24 hours in vacuum to obtain a filter paper disc containing a mixture of molybdenum source and sulfur source airgel. Then put it in a porcelain boat, put the porcelain boat into the constant temperature zone of the tube furnace, first pass 200mL / min nitrogen gas for 30min to remove the air, then pass 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com