Quartz boat and solar cell diffusion process

A solar cell and diffusion process technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the deviation of the inter-chip PN junction diffusion doping longitudinal concentration distribution consistency, affect the debugging of electrode printing and sintering process, and the inter-chip PN junction electricity. Problems such as poor performance consistency, to achieve the effect of optimizing the impurity redistribution process, improving performance stability, improving stability and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

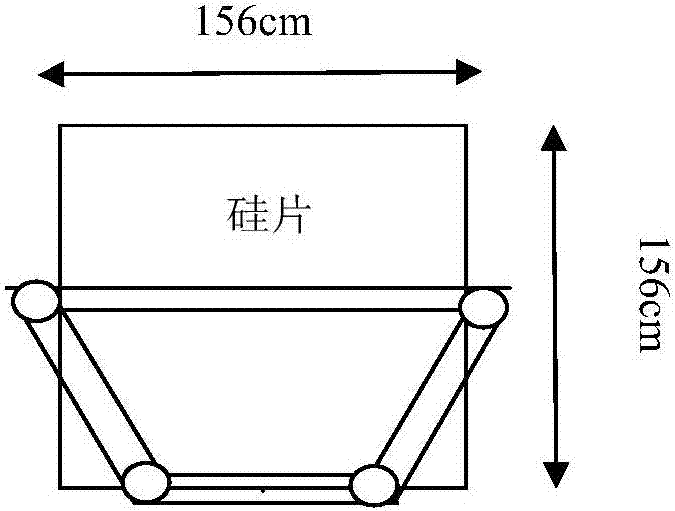

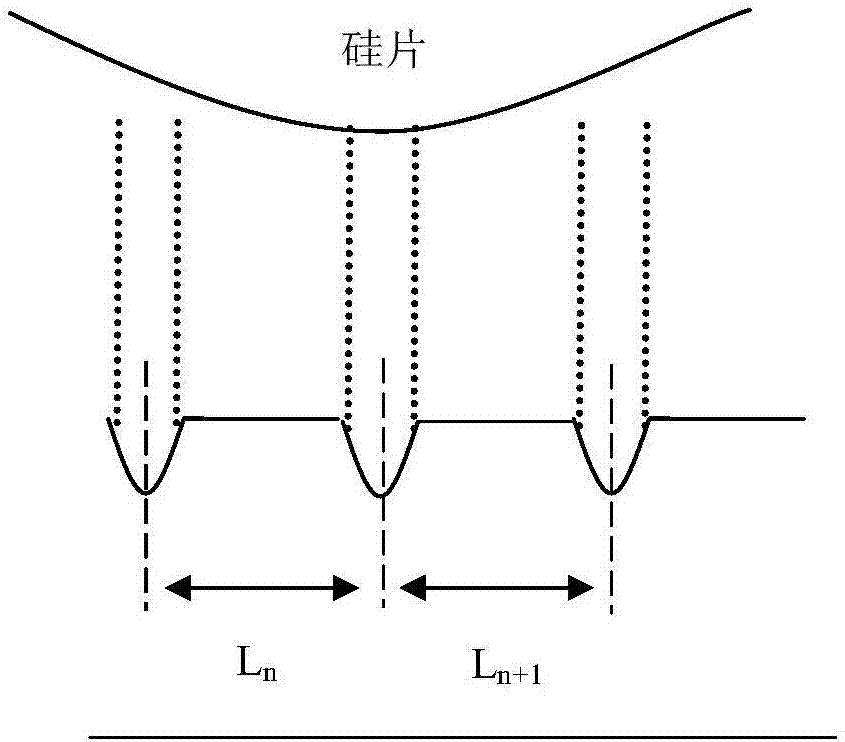

[0035] A quartz boat such as figure 1 and figure 2 As shown, it includes 4 trough rods (in the actual application process, the two ends of the quartz boat also include two quartz plates for fixing the trough rods), and each trough rod is provided with several corresponding ones for placing silicon wafers The tooth space between the adjacent tooth spaces on the slot bar increases in proportion to the first tooth space at the intake end.

[0036] In this embodiment, the minimum value of the tooth spacing (L 1 ) is 2mm, such as figure 1 Shown; common ratio of tooth spacing (L n+1 / L n ) is 1.009, such as image 3 Shown; the maximum tooth spacing is 11.895mm.

[0037] In the present embodiment, there are 200 slots on each grooved bar; the quartz boat can be loaded with 200 silicon wafers.

[0038] A kind of solar cell diffusion process, realized in the above-mentioned quartz boat of this embodiment, comprises the following steps:

[0039] (1) Boat-in process: Insert the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com