Thawing equipment for food detection

A food detection and equipment technology, applied in the field of thawing equipment, can solve the problems of affecting work efficiency, unadjustable thawing speed, slow thawing speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

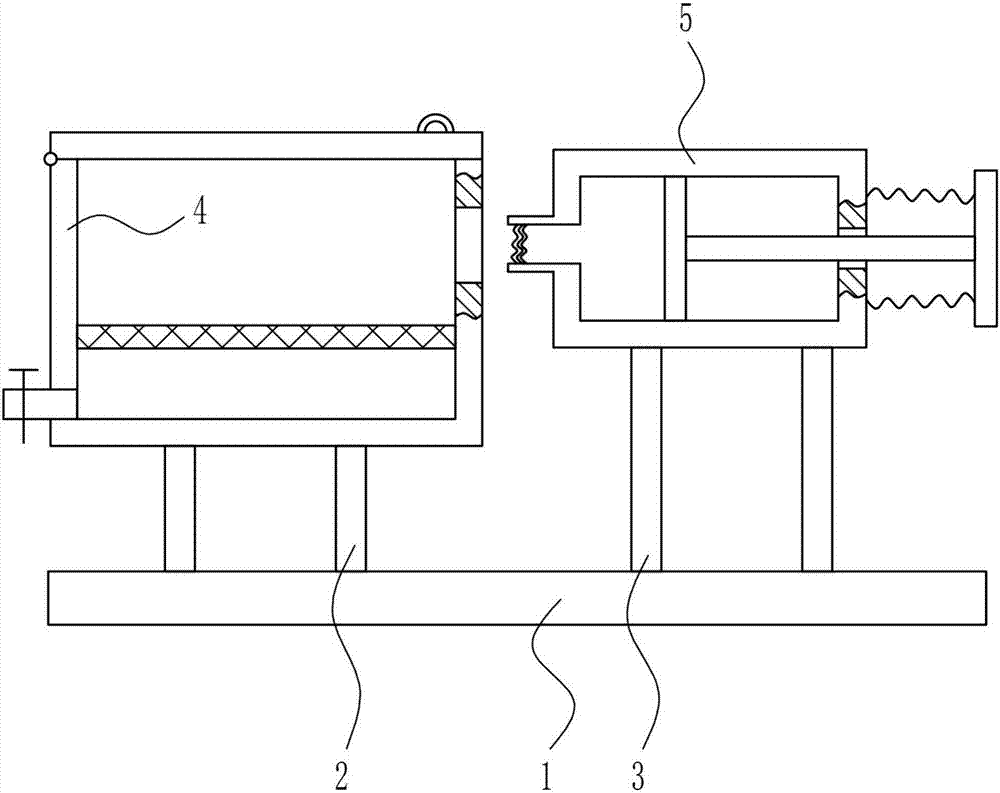

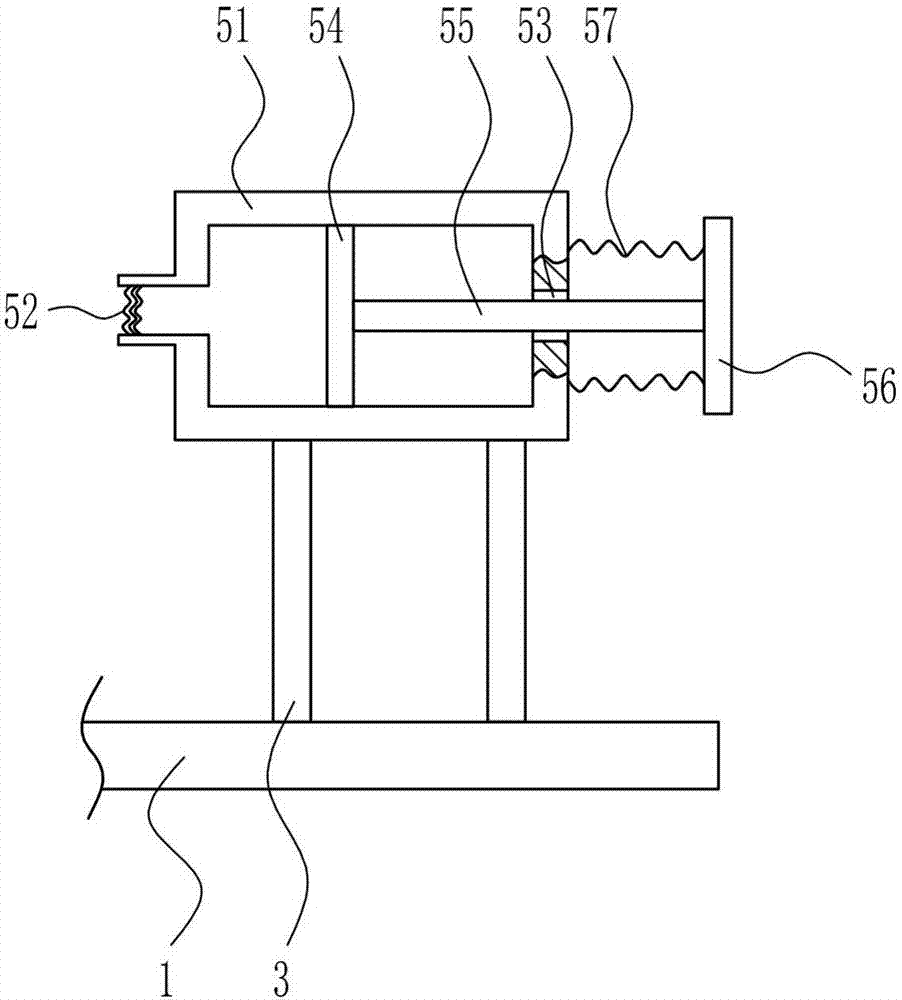

[0029] A kind of thawing equipment for food testing, such as Figure 1-5 As shown, it includes a bottom plate 1, a first pole 2, a second pole 3, a placement device 4, and a thawing device 5. The left and right sides of the top of the bottom plate 1 are symmetrically provided with the first pole 2, and the left and right sides of the top of the bottom plate 1 are symmetrical. A second pole 3 is provided, a placement device 4 is provided on the top of the first pole 2, and a thawing device 5 is provided on the top of the second pole 3, and the placement device 4 is on the left of the thawing device 5.

Embodiment 2

[0031] A kind of thawing equipment for food testing, such as Figure 1-5 As shown, it includes a bottom plate 1, a first pole 2, a second pole 3, a placement device 4, and a thawing device 5. The left and right sides of the top of the bottom plate 1 are symmetrically provided with the first pole 2, and the left and right sides of the top of the bottom plate 1 are symmetrical. A second pole 3 is provided, a placement device 4 is provided on the top of the first pole 2, and a thawing device 5 is provided on the top of the second pole 3, and the placement device 4 is on the left of the thawing device 5.

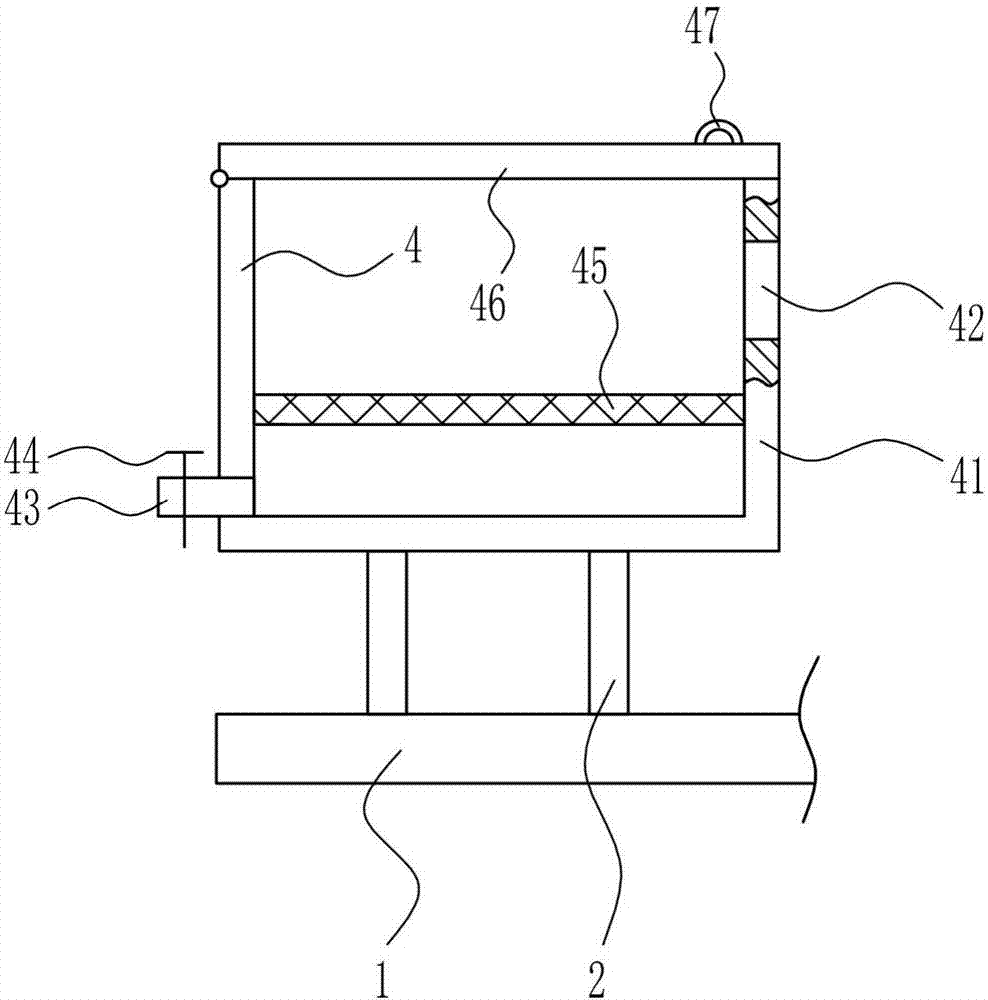

[0032] The placement device 4 includes a casing 41, an outlet pipe 43, a valve 44, a net plate 45, a cover plate 46 and a handle 47. The top of the first pole 2 is provided with a casing 41, and the top of the right wall of the casing 41 has a first pass. The hole 42, the lower part of the left wall of the box body 41 is provided with a water outlet pipe 43, the water outlet pip...

Embodiment 3

[0034] A kind of thawing equipment for food testing, such as Figure 1-5 As shown, it includes a bottom plate 1, a first pole 2, a second pole 3, a placement device 4, and a thawing device 5. The left and right sides of the top of the bottom plate 1 are symmetrically provided with the first pole 2, and the left and right sides of the top of the bottom plate 1 are symmetrical. A second pole 3 is provided, a placement device 4 is provided on the top of the first pole 2 , a thawing device 5 is provided on the top of the second pole 3 , and the placement device 4 is on the left of the thawing device 5 .

[0035]The placement device 4 includes a casing 41, an outlet pipe 43, a valve 44, a net plate 45, a cover plate 46 and a handle 47. The top of the first pole 2 is provided with a casing 41, and the top of the right wall of the casing 41 has a first pass. The hole 42, the lower part of the left wall of the box body 41 is provided with a water outlet pipe 43, the water outlet pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com