Blade electric vehicle transmission with novel lubrication structure

A pure electric vehicle and lubrication structure technology, applied in the field of pure electric vehicle transmission, can solve the problems of increased manufacturing difficulty and cost, decreased transmission efficiency of the transmission, and inability to achieve lubricating effects, etc., so as to save consumption, reduce the amount of lubricating oil, The effect of lowering the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

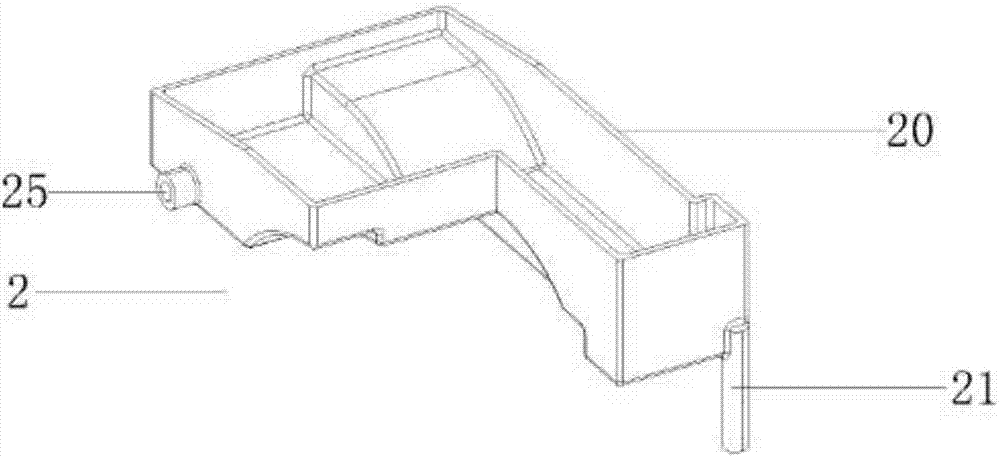

[0019] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment: see Figure 1-4 ,

[0020] A pure electric vehicle transmission with a new lubricating structure, including a transmission case 1, a temporary oil storage box 2 is provided on the top side of the transmission case body, and a lubricating oil 30 is stored on the bottom side, and the temporary oil storage box 2 is provided with several The lubricating oil drip hole 3 is located on the lower side of the temporary oil storage box 2 and above the lubricating oil surface. The transmission input shaft 4 and the intermediate coupling shaft 5 connected by gear transmission are arranged. The gear transmission on the intermediate coupling shaft 5 is connected to the differential main shaft. The reduction gear 6 (or it can also be called the differential outer ring gear), the lower side of the differential main reduction gear 6 is immersed in the lubricating oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com