Zero-energy-consumption seawater washing and purifying method and device for marine engineering engine tail gas

A marine engineering and engine technology, applied to exhaust devices, engine components, combustion engines, etc., can solve the problems of low-efficiency gas-solid heat transfer, low energy consumption, and little effect, and achieve remarkable technical effects. Low energy consumption and the effect of improving energy efficiency indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

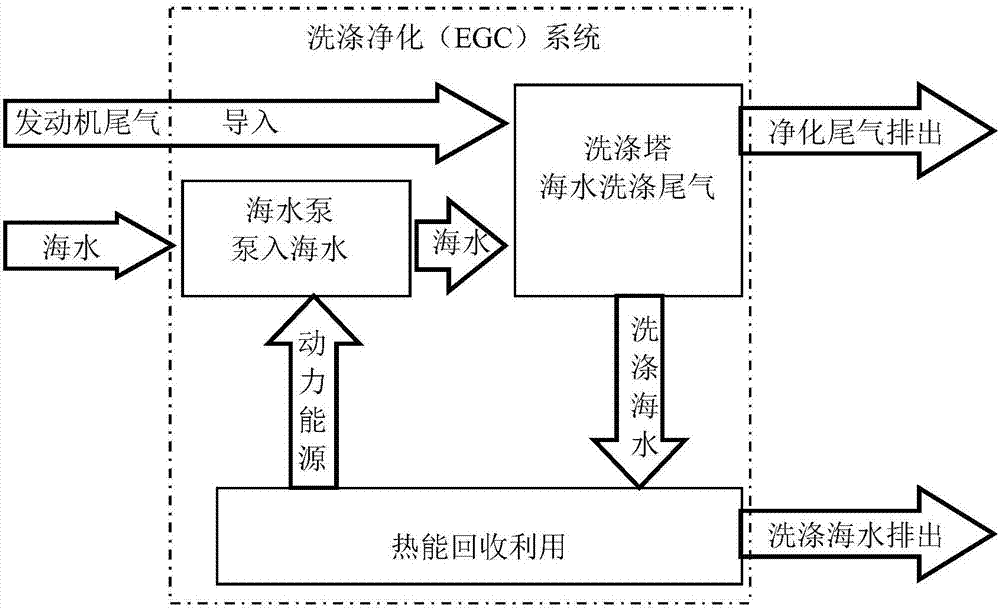

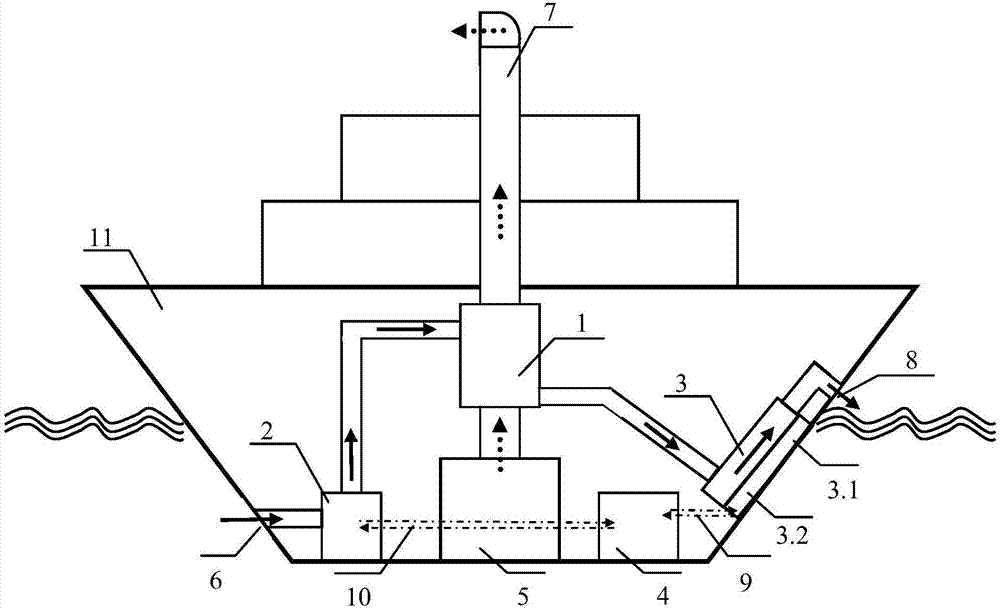

[0024] Embodiment 1: It is the basic embodiment of the seawater washing and purification method for zero-energy marine engineering engine tail gas of the present invention, as attached figure 1 As shown, the implementation steps include introducing engine exhaust gas to the washing tower of the washing and purification system, pumping seawater into the washing tower by the seawater pump, washing the engine exhaust gas with seawater in the washing tower, and discharging the cleaned exhaust gas and washed seawater out of the washing and purification system, Before the washed seawater is discharged from the washing and purification system, it goes through a heat energy recovery step, and the heat energy recovery step recovers the waste heat energy of the washed seawater and uses it as the power energy of the seawater pump.

Embodiment 2

[0025] Embodiment 2: is the embodiment based on embodiment 1. Said recovery of waste heat energy from washing seawater as the power energy of the seawater pump is to use the temperature difference between the washing seawater and the ambient seawater to generate electricity and use the generated electric energy as the power energy of the seawater pump.

[0026] A further embodiment is that the temperature difference generates electricity and uses the generated electric energy as the power source of the seawater pump, and the electricity generated by the temperature difference is used to adjust the seawater flow of the seawater pump, so as to realize the self-stabilizing and constant temperature operation of the seawater washing and purification system.

Embodiment 3

[0027] Embodiment 3: it is another embodiment on the basis of embodiment 1. The step of recovering waste heat energy from washing seawater is heating.

[0028] In another embodiment, the step of recovering waste heat from seawater washing is refrigeration.

[0029] In another embodiment, the step of recovering waste heat from seawater washing is seawater desalination.

[0030] In the above embodiments, the original load of the power system of the marine engineering facility is reduced to free up the corresponding electric power, and then the power system of the marine engineering facility uses the corresponding electric power output as the power energy of the seawater pump, and also realizes the recovery of waste heat energy from washing seawater as a seawater pump The purpose of power energy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com