Textile singeing production technology process

A production process and airflow technology, applied in the field of textile production, can solve the problems of inconvenient dust removal and poor singeing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

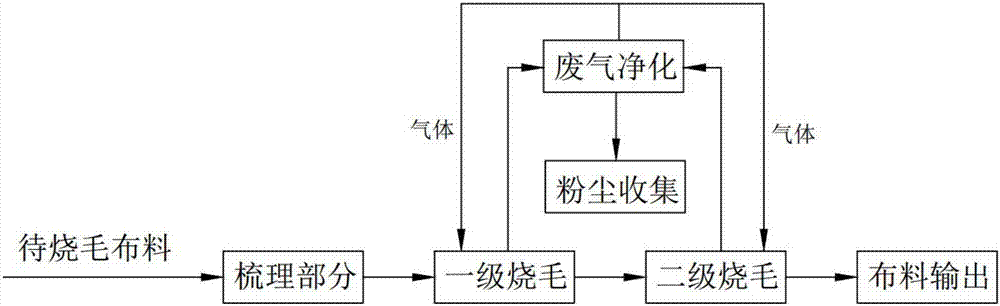

[0037] Refer to the attached figure 1 A textile singeing production process flow in Embodiment 1 of the present invention is described.

[0038] A kind of textile singeing production technological process, comprises the following steps:

[0039] (a) combing part, the fiber on the surface of the cloth 2 is subjected to sizing and combing through the carding assembly 4 through the carding assembly 4 and utilizing a negative pressure adsorption once;

[0040] (b) For the singeing part, the cloth 2 after being shaped and carded in ...

Embodiment 2

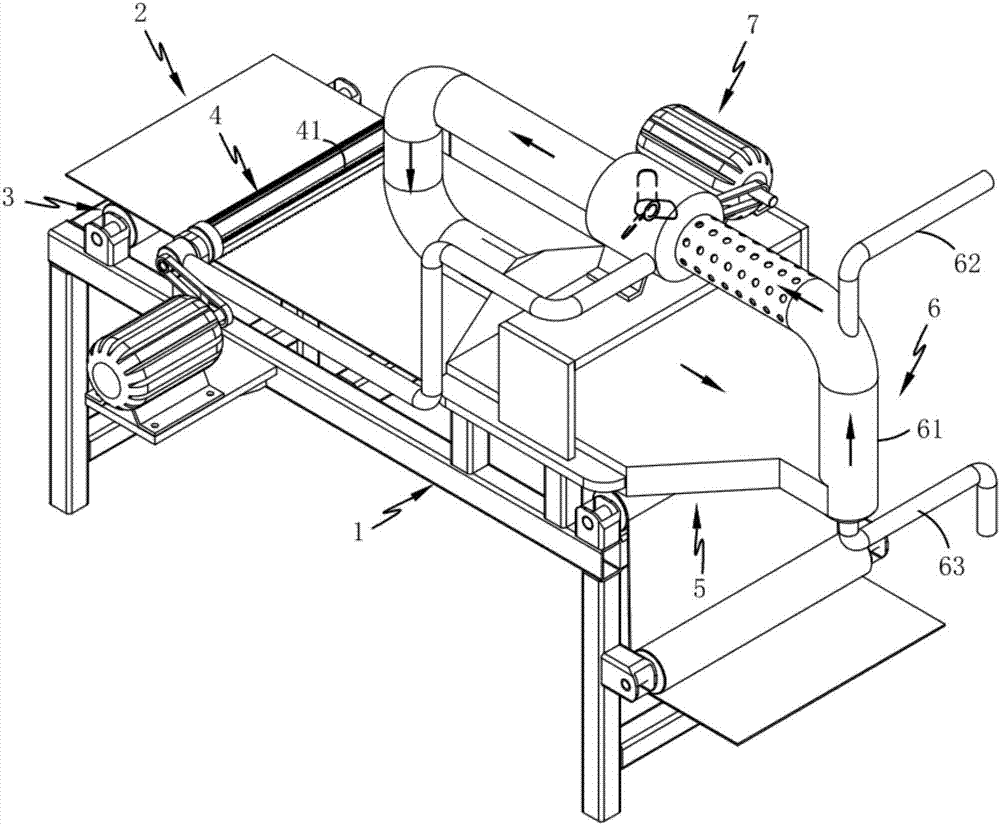

[0055] Reference attached Figure 2-9 A cloth negative pressure finishing and hair removal device according to the second embodiment of the present invention is described.

[0056] Such as figure 2 , 3 , 4, 5, 6 and 7, a cloth negative pressure finishing hair removal device, including a frame 1 and a cloth guide roller 3 that is rotatably mounted on the frame 1 for the tension and conduction of the cloth 2, also includes:

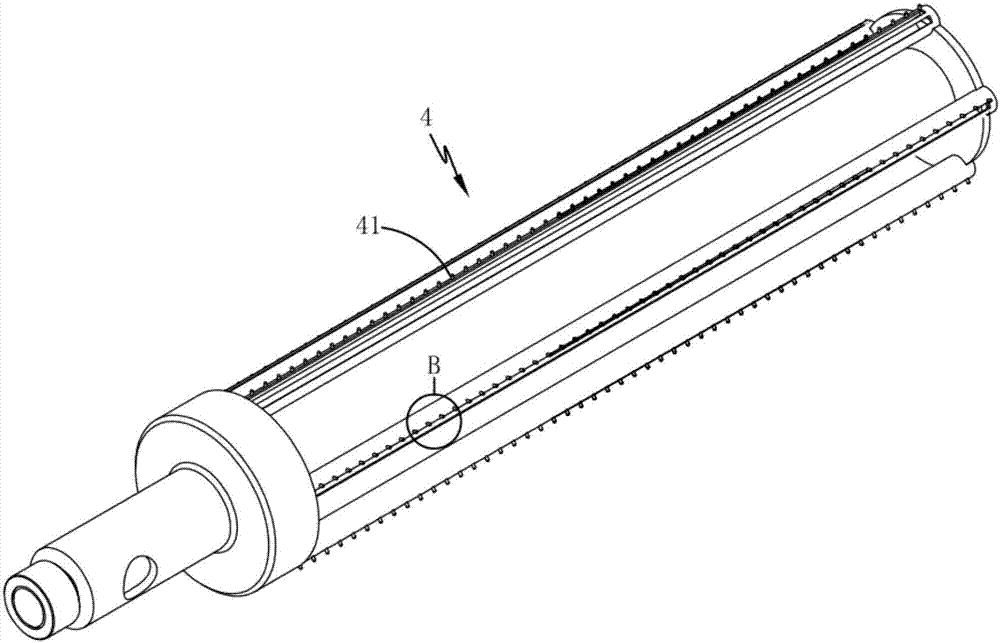

[0057] Combing assembly 4, which is rotatably mounted on the frame 1 and positioned above the cloth 2, the combing assembly 4 includes an adsorption portion 41 arranged thereon, and the adsorption portion 41 is attached to the cloth during rotation. 2. The fibers on the surface are erected and adsorbed and pulled to keep them in an upright state;

[0058] Negative pressure depilation assembly 5, described negative pressure depilation assembly 5 is arranged on the top of cloth 2 and between it and cloth 2 forms fluff stereotyped space 50, the fiber after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com