Preparation method of white carbon black/rubber composite

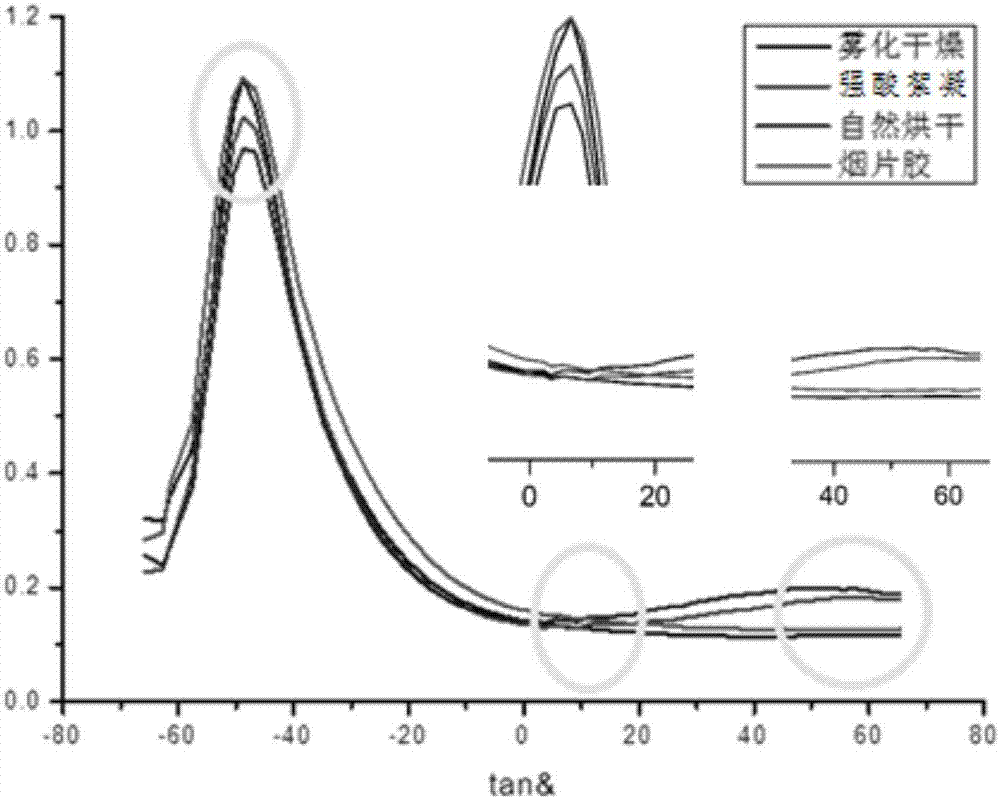

A technology of composite materials and silica, which is applied in the field of preparation of silica/rubber composite materials, can solve problems such as easy agglomeration, difficult dispersion of silica, and poor performance of rubber materials, so as to achieve high preparation efficiency and improve microscopic dispersion Grade, use environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

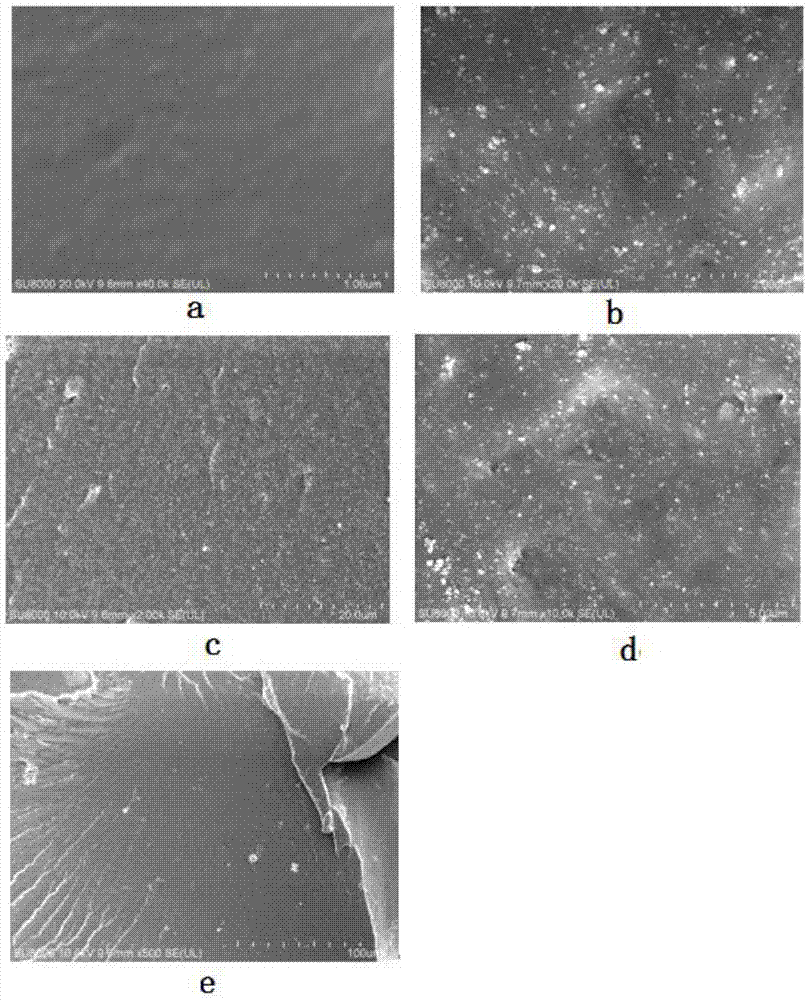

[0020] The preparation method of the silica / rubber composite material involved in this embodiment is also called the atomization drying method, and its process includes three steps of preparing the masterbatch mixture, preparing the masterbatch and preparing the composite material:

[0021](1) prepare masterbatch mixed solution: at first the water and white carbon black of setting mass fraction are mixed and stirred, and the mass percent concentration that obtains 800g is dispersed with high-speed disperser is 25% white carbon black aqueous dispersion, then Use an all-round planetary ball mill to process the silica water dispersion for 4 hours to obtain a silica slurry, then add 166.6g of natural latex to the silica slurry for stirring treatment, and finally 30g of it is subjected to ultrasonic treatment with a power of 750W for 5min The Si69 aqueous solution with a mass percentage concentration of 20% is added to the white carbon black slurry to be configured as a masterbatch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com